A shower cabin is a stylish, comfortable and functional alternative to a regular bath. True, for comfortable use of the cabin it is not enough to simply install it and connect communications. The owner will have to take care of a number of important details, which include seals - special devices that ensure the tightness of the structure. When purchasing a new shower cabin, they are included in the kit, but there are times when the seal needs to be purchased separately.

Seals for shower cabins

The difficulty lies in the fact that such parts have different configurations and are made of different materials, so choosing what you need can be quite difficult.

Seals come in different shapes

Why do you need a seal?

The main task of the seal is to prevent water from getting out of the shower stall, which will cause puddles on the bathroom floor and the humidity in the room will be too high.

Seals are necessary to prevent water from entering the shower stall onto the floor

It is a dense strip that is laid around the perimeter of panels and other parts of the structure to ensure tight contact between:

- swing or sliding doors;

- adjacent panels of the shower cabin;

- vertical parts of the structure and pallet;

- doors and tray;

- cabin panels and bathroom walls.

The photo shows installed seals

In order for the seal to fully perform its functions, it must meet the following criteria:

- resistance to high humidity;

- resistance to temperature changes;

- elasticity and good adhesion to the surface;

- strength and reliability.

Silicone seal

Important: despite the fact that the sealing profile may seem like an insignificant detail, it is not recommended to save on its purchase. Cheap products tend not only to wear out quickly, but also to accumulate dirt and moisture, which can lead to the appearance of fungus, mold and bacterial growth.

Ceramic baseboards and tiles

If the bathroom walls are finished with ceramic tiles, you can close the corner between the bathtub and the wall using a standard baseboard, which is purchased along with the main coating material.

The method is ideal for those cases when renovations are being carried out with an already installed bathroom - no special calculations are required, you just need to try on the bottom row of tiles and cut them at the required distance.

Joining using cut tiles

The method is almost similar to the previous one, when the space between the bathtub and the wall is covered with tiles cut to size. However, the side of the bathroom must be wide enough, otherwise the tiles will chip.

True, there are disadvantages here too - if you need to replace the bathroom, the finishing will have to be seriously damaged. But the use of ceramics gives another important advantage - it is laid on mineral glue and grouted with mineral grout. The fungus starts quite rarely in such conditions.

There is also a method where the bathtub “cuts” directly into the tile covering. However, it requires preliminary fitting and special accuracy. The lower and upper edges of the side with the bathtub installed are marked on the wall.

After this, the plumbing fixture is taken out of the room, and the cladding is done above and below the marked lines. After final installation, the joint is sealed with standard tile grout.

Types of seals

There are several options for seals, which differ from each other in size and cross-section, and are also made of different materials.

Shape (type) of seal

| Type of seal | Where is it used? |

T-shaped | The fittings are installed at the bottom of the cabin door to prevent water from flowing out from under it onto the bathroom floor. |

A-shaped | Used to seal joints between two glass panels, as well as between a wall and glass. |

C-shaped | It is mounted at the bottom of the door, as well as at the junction points of the structure. |

U-shaped | A universal seal that can be used in any location. |

H-shaped | Suitable for shower cabins of non-standard shape and where the sheets do not join at right angles. |

Petal (dropper) | The fittings consist of two parts (petals): one covers the cabin threshold and seals the gap, and the second directs water splashes inside the cabin. It is especially necessary in cases where the shower drain is located directly in the floor. |

seals for shower cabins

In addition to the above types of seals, there are special profiles that are designed for installation on radius equipment. Since conventional fittings on curved glass do not hold up well, fly off from the extreme points, gather in folds and allow moisture to pass through, products with a certain bend are produced for radius cabins.

Seal for radius shower door

Silicone seals

GC Matins offers a wide range of extruded silicone seals made of biologically inert materials based on siloxane rubber (silicone).Due to their unique properties, silicone rubber seals have found wide application in various industries.

Silicone profiles are used as seals for various types of connections and can be used in any climatic zones over a wide temperature range from -60 oC to +315 oC.

Silicone seals are resistant to ozone, sea and fresh water (including boiling water), alcohol, mineral oils and fuel, weak solutions of acids and alkalis.

Scope of application of silicone seals:

Heat-resistant seals in bakery ovens, smoking ovens, proofers and drying ovens

Frost-resistant seals for refrigerators and freezers

Universal seals for windows, doors, portholes, hatches in machine and shipbuilding

Used as insulation and sealing of heat and gas removal equipment

Due to the high electrical insulating properties of silicone rubber, they are used as insulation for output and installation wires of electrical equipment, current-carrying elements of electrical devices, etc.

Used as a substrate for thermal knives in packaging equipment (non-stick properties)

Our company offers silicone sealants for various purposes, hardness and a wide range of colors, including transparent. Profiles made of silicone rubber are manufactured both in a standard configuration, from an assortment of dies available, and according to the technical specifications (drawing) of the customer.

The catalog below presents the most common types of silicone seals.

Catalog of silicone seals (profiles)

| Sectional profile | Profile number | Dimensions axbxcxd (mm) | Weight 1 l.m. (gram.) |

| 1 | 18x24x3.5 | 220 | |

| 2 | 36×20 | 400 | |

| 3-1 | 23x14x19 | 210 | |

| 3-2 | 23x12x18 | 170 | |

| 3-3 | 23x14x17 | 180 | |

| 3-4 | 20x12x17 | 160 | |

| 3-5 | 16x19x19 | 260 | |

| 4-1 | 17x19x7.0x5.5 | 170 | |

| 4-2 | 17x19x4.5x4.5 | 170 | |

| 5-1 | 22x18x20 | 230 | |

| 5-2 | 22x23x18 | 300 | |

| 5-3 | 270 | ||

| 5-4 | 19x13x17 | 170 | |

| 5-5 | 12x10x12 | 110 | |

| 5-6 | Silicone seal for oven door ledge Analogue VIGE 754152.077 | 185 | |

| 6-1 | 13x11x16 | 110 | |

| 6-2 | 20x11x16 | 140 | |

| 7-1 | 11x16x8x14 | 155 | |

| 7-2 | 11x16x9x16 | 180 | |

| 7-3 | 11x15x9x14 | 150 | |

| 7-4 | 10x17x8x16 | 195 | |

| 7-5 | 11x18x9x18 | 235 | |

| 7-6 | 13x11x6x11 | 100 | |

| 7-7 | 13x12x8x11 | 85 | |

| 7-8 | 11×17.5x12x15 | 100 | |

| 8-1 | 11x21x13x18 | 165 | |

| 8-2 | 16x21x13x18 | 210 | |

| 8-3 | 16x21x10x18 | 250 | |

| 8-4 | 8x13x8x12 | 90 | |

| 8-5 | 13x13x8x12 | 110 | |

| 8-6 | 19x26x16.5x24 | 300 | |

| 9 | 14x15x20 | 175 | |

| 10 | 18x24x22 | 320 | |

| 11 | 24x10x10x5 | 320 | |

| 12 | 10x20x14x4 | 170 | |

| 13 | 12x20x2 | 150 | |

| 14-1 | 2.5x20x1.5x1.5 | 53 | |

| 14-2 | 3.5x21x2.0x2.5 | 83 | |

| 14-3 | 3.5x25x2.0x2.5 | 100 | |

| 14-4 | 5.0x28x4.0x3.0 | 174 | |

| 14-5 | 4.0x31x2.0x2.5 | 106 | |

| 14-6 | 7.0x25x1.5x2.5 | 110 | |

| 14-7 | 13x32x2.0x2.0 | 180 | |

| 14-8 | 7.5x28x3.0x3.0 | 175 | |

| 14-9 | 12x35x2.5x2.5 | 210 | |

| 14-10 | 14x52x4.0x5.0 | 460 | |

| 14-11 | 15x54x6.0x5.5 | 650 | |

| 14-12 | 7.5x28x1.5x2.5 | 120 | |

| 14-13 | 9.0x30x2.5x3.0 | 190 | |

| 14-14 | 9.0x35x3.0x3.0 | 230 | |

| 14-15 | 4.0x28x1.0x2.0 | 60 | |

| 14-16 | 10.5x40x2.0x4.0 | 295 | |

| 14-17 | 9.0x36x3.5x3.5 | 260 | |

| 14-18 | 8.5x30x2.0x3.5 | 160 | |

| 14-19 | 8.5x27x3.0x3.0 | 195 | |

| 14-20 | 10.5x33x3.5x2.0 | 250 | |

| 14-21 | 10.5x25x1.5x2.0 | 105 | |

| 14-22 | 11.5x41x3.5x4.0 | 320 | |

| 14-23 | 3.0x19x1.5x1.5 | 50 | |

| 14-24 | 14.5x40x2.5x3.5 | 280 | |

| 14-25 | 43x85x4.0x4.0 | 950 | |

| 15-1 | 15.5x11x6x5.5 | 130 | |

| 15-2 | 20×20.8x8x8 | 235 | |

| 15-3 | 19.5x17x8x7 | 290 | |

| 16 | 18x24x13x3 | 260 | |

| 17 | 14x15x22 | 210 | |

| 18-1 | 17x12x6x6 | 160 | |

| 18-2 | 11×8.5x3x4.5 | 75 | |

| 18-3 | 16x10x5x5 | 130 | |

| 18-4 | 13x8x3x4 | 75 | |

| 18-5 | 6,5×6,5×2,7×3 | 40 | |

| 18-6 | 5x6x3x3.6 | 35 | |

| 18-7 | 16x7x3x8 | 100 | |

| 18-8 | 27x28x14x10 | 620 | |

| 19 | 21×20 | 155 | |

| 20 | 11×6,5×2,5 | 50 | |

| 22-1 | 20x15x2 | 95 | |

| 22-2 | 19x15x2.5 | 100 | |

| 23 | 6x6x1 | 25 | |

| 26 | 4.5x10x10 | 60 | |

| 27-1 | 12×17 | 240 | |

| 27-2 | 17×20 | 385 | |

| 27-3 | 17×24 | 480 | |

| 27-4 | 16×12 | 210 | |

| 27-5 | 6×6 | 37 | |

| 27-6 | 7×16 | 115 | |

| 27-7 | 13×24 | 335 | |

| 27-8 | 7,5×6,1 | 50 | |

| 27-9 | 19,5×11,5 | 220 | |

| 27-10 | Frost-resistant seal for hatches (fits into a frame according to customer dimensions) | 700 | |

| 27-11 | 25 | ||

| 29 | 7×7 | 30 | |

| 30 | 7×5,5×5 | 32 | |

| 31 | 36×8,5 | 90 | |

| 32-1 | 11x7x9 | 80 | |

| 32-2 | 9x6x9 | 50 | |

| 33-1 | 9,5×1,9 | 16 | |

| 33-2 | 9,5×1,7 | 16 | |

| 34-1 | 13×3.6x6x0.8 | 40 | |

| 34-2 | 13×4,8×6,5×1,5 | 55 | |

| 34-3 | 13×5,5×6,5×1,8 | 70 | |

| 34-4 | 14×5.5x7x2.5 | 65 | |

| 34-5 | 18.4x7x10.4x2 | 100 | |

| 34-6 | 20×4.5x14x1.5 | 150 | |

| 35 | 19.5x7x4.5 | 80 | |

| 36-1 | 10x14x3x3.5 | 110 | |

| 36-2 | 10x15x4.5x2.5 | 90 | |

| 36-3 | 10x15x5x2.5 | 95 | |

| 36-4 | 11x11x5x3.5 | 95 | |

| 36-5 | 10x11x5x2.5 | 80 | |

| 36-6 | 15x18x6x4.5 | 200 | |

| 36-7 | 12x12x5x3.5 | 120 | |

| 36-8 | 12x25x5x3.5 | 270 | |

| 36-9 | 10x22x5x3 | 225 | |

| 36-10 | 6x8x2.5x1.5 | 40 | |

| 36-11 | 5x10x2x1.5 | 40 | |

| 36-12 | 16x16x10x3 | 160 | |

| 36-13 | 3.2x3x1.8x0.7 | 7 | |

| 36-14 | 4.2x6x1.3x1.5 | 23 | |

| 36-15 | 15x28x6x4 | 310 | |

| 37-1 | 21x4x1.5 | 45 | |

| 37-2 | 27x4x1 | 50 | |

| 37-3 | 25x4x1 | 40 | |

| 37-4 | 25x12x1.5 | 210 | |

| 38-1 | 8.5x13x5x2 | 70 | |

| 38-2 | 7.5x13x5.5x1 | 50 | |

| 38-3 | 7.5×9.5x5x1 | 35 | |

| 38-4 | 7x12x5x1 | 30 | |

| 38-5 | 10x13x7x1 | 70 | |

| 39 | 23x8x11x3 | 120 | |

| 40-1 | 43x13x18x3 | 220 | |

| 40-2 | 44x15x21x3 | 270 | |

| 41-1 | 20x19x16x15 | 175 | |

| 41-2 | 20x17x11x10 | 200 | |

| 42 | 15x18x12x10 | 135 | |

| 43 | 12x7x8x4 | 55 | |

| 44 | 30x18x10x9 | 260 | |

| 45-1 | 9x30x1.5x1.5 | 100 | |

| 45-2 | 9x26x1.6x1.6 | 90 | |

| 46 | 23x8x3.5 | 115 | |

| 47-1 | 20x20x3.5 | 210 | |

| 47-2 | 17x17x3 | 160 | |

| 48-1 | 14x24x9.5 | 320 | |

| 48-2 | 16x24x9.5 | 288 | |

| 49 | 26x20x21x6 | 440 | |

| 50-1 | 14.5×13.5x4x2 | 165 | |

| 50-2 | 12x10x4x2.5 | 90 | |

| 50-3 | 20x16x7x2 | 250 | |

| 50-4 | 20x16x8x4 | 300 | |

| 50-5 | 17x12x3x2.5 | 150 | |

| 50-6 | 19.5x12x3x3 | 170 | |

| 50-7 | 11x20x9x2.5 | 200 | |

| 50-8 | 16,5×14,5×5,5×2,5 | 190 | |

| 50-9 | 17x22x2x2 | 170 | |

| 50-10 | 13x15x4x2 | 125 | |

| 51-1 | 25x16x11.5x4 | 210 | |

| 51-2 | 25x16x11.5×0 | 210 | |

| 52 | 31x16x20x13 | 290 | |

| 53 | 11×16,5×9 | 150 | |

| 54 | 9x12x4.5 | 60 | |

| 55 | 15x12x12 | 135 | |

| 56 | 16×16,5×18 | 240 | |

| 57-1 | 15x12x8x11 | 140 | |

| 57-2 | 22x20x10x9 | 295 | |

| 57-3 | 18x15x9x9 | 200 | |

| 58-1 | 15×9.5x10x5.5 | 120 | |

| 58-2 | 18x11x12x6 | 185 | |

| 58-3 | 17x11x10.5x4.5 | 165 | |

| 59 | 15x31x24x5 | 530 | |

| 60-1 | 17x11x5 | 190 | |

| 60-2 | 21.5x11x5 | 250 | |

| 61-1 | 19x24x25x4 | 320 | |

| 61-2 | 28x32x35x7 | 595 | |

| 62 | 10x11x9.5x1 | 85 | |

| 63 | 28x25x20 | 360 | |

| 64 | 27x6x3 | 130 | |

| 65 | 12x12x3 | 135 | |

| 66 | 46x17x2.5x13 | 250 | |

| 67 | 15×11 | 85 | |

| 68-1 | 26x16x21 | 530 | |

| 68-2 | 27x20x13 | 360 | |

| 68-3 | 24x21x14 | 380 | |

| 68-4 | 19.5x16x17 | 371 | |

| 68-5 | 12x7x15 | 190 | |

| 68-6 | 11x7x10.5 | 120 | |

| 68-7 | 11,5×7,7×9,7 | 110 | |

| 68-8 | 11x7x15 | 110 | |

| 68-9 | 26x21x16 | 420 | |

| 68-10 | 31×23,5×10 | 325 | |

| 68-11 | 14x10x6 | 85 | |

| 68-12 | 12x10x8 | — | |

| 69 | 25x20x18x14 | 315 | |

| 70 | 25x19x14x2.5 | 210 | |

| 71 | 32x12x12x2 | 140 | |

| 72 | 28x24x25x9 | 490 | |

| 73 | 29x19x17x8 | 295 | |

| 74 | 23×21 | 350 | |

| 75 | 12x14x7x4 | 95 | |

| 76-1 | 11×10,5×1 | 45 | |

| 76-2 | 9.5x15x1 | 50 | |

| 77 | 11x8x6 | 70 | |

| 78-1 | 6.5x9x5.5 | 50 | |

| 78-2 | 7.5x11x6.5 | 70 | |

| 79-1 | 12.5x12x9 | 75 | |

| 79-2 | 14×14,5×10 | 145 | |

| 80 | 27x17x10x8.5 | 290 | |

| 81 | 31×14.5x13x10 | 230 | |

| 82 | 6x8x1x2 | 30 | |

| 83 | 7×10 | 40 | |

| 84 | 27x27x36 | 430 | |

| 85 | 10x10x5.5x2 | 55 | |

| 86 | 32x24x17.5x14 | 620 | |

| 87 | 10.5x19x16 | 195 | |

| 88 | 24x20x17x3 | 310 | |

| 89 | 8x10x14x1 | 55 | |

| 90 | 28x25x14x20 | 260 | |

| 91 | 5,2×11,5×1,2 | 50 | |

| 92 | 15×6.5x4x1 | 55 | |

| 93 | 18×12.5x7x7 | 185 | |

| 94 | 18x18x3 | 125 | |

| 95 | 18x25x16x10.5 | 210 | |

| 96 | 18x25x16x3 | 150 | |

| 97 | 12x15x14 | 170 | |

| 98-1 | 15x8x11x6 | 80 | |

| 98-2 | 156 | ||

| 99 | 13x20x8x1.5 | 200 | |

| 100 | 16,4×7,1×3,5 | 70 | |

| 101 | 10,7×12,9×4,4×4,5 | 70 | |

| 102-1 | Silicone seal for Rotor-Agro ovens | 190 | |

| 102-2 | Silicone seal for Rotor-Agro ovens | 140 | |

| 103 | Silicone seal for baking ovens Monsoon-Rotor models 55, 77, 99, 250, 350. Seal No. 146 is used on the bottom of the oven | 180 | |

| 104 | Silicone seal for UNOX and FOTON ovens | 230 | |

| 105-1 | Silicone seal for drying line | 450 | |

| 105-2 | Heat Resistant Aging Furnace Door Seal | 340 | |

| 106 | Silicone sealant for modular building structures Analogue VIGE 751392.118 | 470 | |

| 107 | Silicone seal for Xpeed automatic tray sealers | 65 | |

| 108 | Silicone seal for main pipeline | 730 | |

| 109 | Silicone seal for chipboard cabinets | 20 | |

| 110 | Silicone seal for Autotherm thermal chamber door | 260 | |

| 111-1 | High Temperature Silicone Profile for Packing Machine | 300 | |

| 111-2 | High Temperature Silicone Backing for PE Film Sealing | 170 | |

| 112 | Analogue VIGE 751392.068 | 300 | |

| 113-1 | 50x30x10 | 660 | |

| 113-2 | 46x30x16 | 785 | |

| 114 | Silicone sealant is used in the production of lamps | 90 | |

| 115-1 | Silicone seal for wafer sheet production furnace No. 115-1 | 115 | |

| 115-2 | Silicone seal for wafer sheet production furnace No. 115-2 | 175 | |

| 116 | Silicone sealant for hatches and portholes | 115 | |

| 117 | Silicone seal for doors of thermal chambers and smoke generators | 40 | |

| 118 | 87 | ||

| 119 | Analogue VIGE 751392.054 | 225 | |

| 120 | 33 | ||

| 121-1 | 6.5×13.5x3x7 | 95 | |

| 121-2 | 10x20x4x12.5 | 240 | |

| 121-3 | 8.5x24x5x13 | 246 | |

| 122-1 | The fender is mounted on the side of the boat along the entire perimeter | 660 | |

| 122-2 | The silicone seal is joined into a ring and mounted on the tank. Used in meat processing plants | 1000 | |

| 123 | Silicone fry stirrer lid seal | 235 | |

| 124 | 53 | ||

| 125 | Silicone seal for vacuum laminator MA-00-763 | 25 | |

| 126 | Silicone seal for hydraulic injection molding machines | 85 | |

| 127 | Silicone sealant is used in the production of lamps | 25 | |

| 128 | CEPI Flour Vibrating Screen Silicone Seal | 490 | |

| 129-1 | Silicone cabin seal for a light jet trainer | 130 | |

| 129-2 | 105 | ||

| 130-1 | Silicone seal for payment terminal | 57 | |

| 130-2 | Silicone seal for sight glass. At the request of the client, it is joined into a ring. | 160 | |

| 131 | Silicone seal for thick display glass | 90 | |

| 132 | 275 | ||

| 133 | Silicone seal for SOTTORIVA proofing cabinet | 250 | |

| 134 | Silicone sealant is used in the production of lamps | 50 | |

| 135 | Silicone sealant is used in the production of lamps | 35 | |

| 136 | 165 | ||

| 137 | Silicone sealant for ceiling tile gaps on ships | 225 | |

| 138 | Silicone seal used in vacuum forming machine | 505 | |

| 139 | 380 | ||

| 140 | 650 | ||

| 141-1 | 20x25x18x22 | 315 | |

| 141-2 | 20x25x15x22 | 365 | |

| 142-1 | 60 Shore Medium Hard Silicone Seal Used in Plastic Bag Making Machine | 117 | |

| 142-2 | Soft silicone seal, hardness 40 Shore, used in plastic bag making machine | 117 | |

| 143 | Silicone seal for vacuum cover of cutter RSM-352 | 200 | |

| 144 | 215 | ||

| 145 | Silicone profile for textile industry | 265 | |

| 146 | Silicone furnace threshold seal Monsoon Rotor. Used on all Monsoon-rotor baking ovens models 55, 77, 99, 250, 350 Installed on the bottom of the door (threshold). Along the rest of the door perimeter, seal No. 103 is used | 265 | |

| 147 | The seal is made with a hardness of 80 Shore | 80 | |

| 148 | 112 | ||

| 149-1 | 5,4×7,5×2,8×2,5 | 34 | |

| 149-2 | 5.5x8.2x3x2.8 | 36 | |

| 149-3 | 32 | ||

| 150 | 306 | ||

| 151 | Silicone seal for vibrating separator (vibrating sieve) | 300 | |

| 152 | Silicone seal for convection oven | 113 | |

| 153 | 268 | ||

| 154 | 18 | ||

| 155 | Silicone seal for vibrating separator (vibrating sieve) | 260 | |

| 156 | 137 | ||

| 157-1 | 12,5×20,5×7,5 | 214 | |

| 157-2 | 10x24x9.5 | 220 | |

| 157-3 | 10x20x8 | 187 | |

| 158 | Silicone seal for the doors of the smoke generator of the thermal chamber for cooking and smoking AUTOTHERM | 455 | |

| 159 | Silicone seal with resin channel | 165 | |

| 160-1 | 14x24x9 | 317 | |

| 160-2 | 16x25x10 | 370 | |

| 160-3 | 22x27x8 | 600 | |

| 160-4 | 10x12x5 | 110 | |

| 160-5 | 12×14.5×8 | 135 | |

| 161 | Silicone seal for bread machine | 281 | |

| 162 | Heat-resistant seal for vulcanization boiler. This seal is joined into a ring according to customer dimensions. | 271 | |

| 163 | 73 | ||

| 164-1 | 185 | ||

| 164-2 | Heat-resistant silicone seal for the tank hatch, joined into a ring, followed by installation on the tank. | 205 | |

| 165 | 240 | ||

| 166 | 55 | ||

| 167 | Silicone seal for vibrating separator (vibrating sieve) | 161 | |

| 168 | Silicone seal for SOTTORIVA proofing cabinet | 140 | |

| 169 | 150 | ||

| 170 | Used to seal the joints of chambers of ELU-20R and AELTK-8-425 installations | 161 | |

| 171 | The seal is manufactured with a hardness of 70 Shore | 351 | |

| 172 | 405 | ||

| 173 | Silicone seal for convection oven | 100 | |

| 174 | 260 | ||

| 175 | Frost-resistant seal for the rear side of a garbage truck | 346 | |

| 176 | Heat-resistant seal for injection molds ORP-STAMPI Italy | 217 | |

| 177 | Seal for press filter | 293 | |

| 178 | 76 | ||

| 179-1 | Gasket No. 179-1 fits into a rectangular frame to seal a double-leaf oven door | 386 | |

| 179-2 | Gasket No. 179-2 fits into a rectangular frame to seal a double-leaf oven door | 480 | |

| 180 | The seal is made with a hardness of 80 Shore | 280 | |

| 181 | 268 | ||

| 182 | Silicone seal for convection oven | 250 | |

| 183 | 600 | ||

| 184 | 582 | ||

| 185 | 237 | ||

| 186 | 241 | ||

| 187 | Heat-resistant seal for injection molds ORP-STAMPI Italy | 57 | |

| 188 | 180 | ||

| 189 | 78 | ||

| 190 | 330 | ||

| 191-1 | Frost-resistant seal for façade sliding and lift-and-slide aluminum doors | 116 | |

| 191-2 | Silicone seal for ZIEL equipment | 175 | |

| 192-1 | Silicone sealant for clean rooms, installed in wall panels for clean rooms | 90 | |

| 192-2 | Silicone sealant for clean rooms, installed in wall panels for clean rooms | 110 | |

| 193 | 125 | ||

| 194 | 250 | ||

| 195 | Silicone sealant is used in the production of lamps (placed on the sharp edge of a metal reflector) | 43 | |

| 196 | Silicone seal for oven door seal | 388 | |

| 197 | Silicone cord for jewelry (used to create bracelets and necklaces). Available in glossy and matte finishes | 70 | |

| 198 | 55 | ||

| 199 | Silicone seal used in a machine for the production of PP/PE bags | 220 | |

| 200 | The seal is manufactured in 5m sections; other multiplicities must be agreed upon upon application. | 220 | |

| 201 | 180 | ||

| 202-1 | 10x10x4 | 108 | |

| 202-2 | 12x12x5 | 154 | |

| 202-3 | 14x14x6 | 210 | |

| 202-4 | 15x15x7 | 231 | |

| 202-5 | 16x16x8 | 260 | |

| 202-6 | 18x18x9 | 325 | |

| 202-7 | 20x20x10 | 400 | |

| 202-8 | 22x22x11 | 481 | |

| 202-9 | 24x24x12 | 575 | |

| 202-10 | 26x26x14 | 650 | |

| 203-1 | 10x10x4 | 105 | |

| 203-2 | 12x12x5 | 148 | |

| 203-3 | 14x14x6 | 197 | |

| 203-4 | 15x15x7 | 217 | |

| 203-5 | 16x16x8 | 236 | |

| 203-6 | 18x18x9 | 302 | |

| 203-7 | 20x20x10 | 372 | |

| 203-8 | 22x22x11 | 451 | |

| 203-9 | 24x24x12 | 540 | |

| 203-10 | 26x26x14 | 600 | |

| 204 | 480 | ||

| 205 | Frost-resistant silicone seal for refrigeration tunnel | 75 | |

| 206 | Silicone seal for vacuum sealing. At the request of the client, it is joined into a large diameter ring. | 295 | |

| 207 | Silicone seal for the oven. Manufactured with a hardness of 80 Shore. At the request of the client, it is joined into a ring for subsequent installation on the door leaf. | 200 | |

| 208 | Profile for sealing rings on hatches of food tankers. The seal is inserted into the groove and pressed against the hatch. We produce both by the meter and in a joined version. | 300 | |

| 209 | Frost-resistant seal for freezer compartment | 370 | |

| 210 | 140 | ||

| 211 | 30 | ||

| 212 | 250 | ||

| 213 | 260 | ||

| 214 | Heat-resistant seal for ALUS equipment | 230 | |

| 215 | Seal for the spray booth (yarn dyeing). At the client's request, the profile is joined into a ring. | 285 | |

| 216 | Autoclave lid seal. Working environment - steam up to 200oC. At the client's request, the profile is joined into a ring. | 310 | |

| 217 | Seal with groove for air supply. At the client's request, the profile is joined into a ring. | 260 | |

| 218 | Autoclave lid seal. The profile is joined into a ring with a circumference of 5000mm | 490 | |

| 219 | An analogue of the Italian seal, at the request of the customer we join it into a ring. | 1850 | |

| 220 | The heat-resistant profile is designed for gas boilers. Application temperature +300oС | 145 | |

| 221 | 250 | ||

| 222 | 75 |

Distinctive advantages of silicone seals

High heat and frost resistance (from -60 oC to +315 oC)

Environmental safety (silicone is inert)

High resistance to ozone, sunlight and solar radiation

High mechanical strength, elasticity and durability (at least 7 years)

Excellent electrical insulating and dielectric properties - no less than 20 kV/mm

Silicone seals are 10 to 20 times more gas permeable than organic rubber seals

Good chemical resistance to many aggressive environments (salt solutions, alcohols, phenols)

Resistance to physiological fluids, sea and fresh water (including boiling water)

Services

Prompt production of a die (for further production of a seal), in the absence of one in our assortment.

Responsible storage of the customer’s dies (for the manufacture of a special, specific seal)

Joining the seal into a ring

Docking the seal into oven frames

Providing samples for testing

Delivery throughout Russia by transport and courier companies.

Types of materials

One of the main characteristics that should be taken into account when choosing a seal is the material used to make the profile (usually rubber, silicone, PVC, thermoplastic elastomer), since each of them has its own advantages and disadvantages.

Rubber seals

Rubber compressor

Rubber shower fittings are the simplest and most inexpensive option. In terms of durability and abrasion resistance, it is inferior to modern materials, and in addition, it can accumulate dust and dirt, but it is not without some advantages. Rubber does not allow water to pass through, is resistant to humidity, most chemicals and can withstand temperature changes from -50 to +100 degrees.

Silicone fittings

Sealant (silicone) for glass in the shower cabin

Silicone products have good performance properties, including strength, resistance to high temperatures, durability and elasticity. They are resistant to mechanical damage, do not crack or cause metal corrosion, fit well to the cabin structure, ensuring its tightness, but are more expensive than rubber fittings.

Important: when choosing a silicone sealant, you should pay attention to the absence of toxic substances in the material, otherwise they will cause fumes that are harmful to health.

One of the types of silicone sealing profiles is magnetic seals. They are produced in the form of strips of a certain shape, which are equipped with magnetic elements along their entire length. These seals are installed on the cabin doors to securely lock them in the closed position. When purchasing magnetic products, you must take into account that each of them is designed for doors that close at a specific angle (90, 135 or 180 degrees). If none of the profiles fits, it is recommended to purchase fittings with a latch, the angle of which can be adjusted independently.

Magnetic seal for shower cabin

Silicone magnetic seal

It should be noted that installing a magnetic seal on the ends of the door necessarily requires the presence of hinges without fixation and a closing mechanism. If the design is equipped with hinges with a closer and a fixed “zero” position, then a so-called thrust profile can be used to protect against leaks. It serves as both a stop for swing doors and protection against splashing water.

Profile for fastening shower glass to the wall

PVC seals

PVC profiles have almost the same advantages as silicone ones. Most often they are installed on moving parts of the cabin to ensure a tight fit. Seals made of polyvinyl chloride are not subject to deformation under the influence of high temperatures, are safe for health and do not change color during operation. A wide range of PVC seals allows you to select a product of the desired width with any cross-section.

PVC seals

Thermoplastic elastomer profile

Thermoplastic elastomer is a synthetic polymer material of the latest generation. Under normal conditions, it has the characteristics of ordinary rubber, but when the temperature rises, the products soften and resemble thermoplastic. The material has a smooth surface and a uniform structure, and after deformation it regains its original appearance. Thanks to this, sealing profiles made of this polymer are durable (the average service life is 10 years), are not subject to cracking or mechanical damage, and are practical to use. The only drawback of profiles made from this material is the high cost.

Thermoplastic elastomer seals

Important: sealing profiles for shower cabins can be soft or hard, and experts recommend using products made in the form of soft tubes. They adhere much better to the joints of the structure, ensuring complete tightness.

What is needed to organize internal sewerage

The internal sewer system collects wastewater from throughout the house and discharges it into the riser.

Sewerage accessories include:

- water seals connecting plumbing fixtures to the pipeline;

- a pipeline that discharges wastewater from the floor into the collector;

- ventilation tube;

- actually, the riser itself;

- sewer bed - a horizontal section of the pipeline through which wastewater flows further from the riser.

When laying pipes, you will need such shaped elements as revisions, tees, elbows, plugs, etc. Without them, it is impossible to ensure drainage according to all the rules.

Shaped elements

Shaped parts for sewerage can otherwise be called connecting parts; they are produced in the following configurations:

coupling - a short piece of pipe with sockets on both sides. Used to connect 2 parts of the pipeline;

adapter (reduction) – used to connect pipes of different diameters. Reduction can be coaxial or eccentric;

tee - this element is indispensable in situations where you need to create a branch extending from the main sewer system, for example, when laying out floors with your own hands;

revision - the same tee, only the outlet is closed with a plug, and the branch itself is small. Used when the sewer is clogged to clean it;

crosspiece - the purpose is the same as that of a tee, but with its help a more complex unit is organized;

- elbow

(bend) – used when turning the pipeline; - non-return valve

- necessary in emergency situations, thanks to it wastewater will not flow back in the event of a malfunction of the drainage system;

plug - during repairs, used to block the sewer.

Sewer fittings are a vital element when laying out the system. Without them, it is impossible to install pipes across the floor or connect them to the riser.

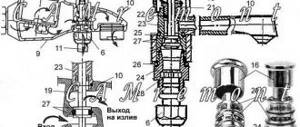

Features of connecting plumbing fixtures

The connection of any plumbing fixture must be organized so that unpleasant odors from the sewer do not leak into the room. The simplest method is to connect through a water seal (or siphon).

The siphon looks like an ordinary pipe in the shape of the letter S, thanks to the water plug, protection against odors is guaranteed. If you do not plan to live in the house regularly, for example, in a country house, then you can consider other methods of protection against odors (dry sewer siphon).

Sewer repair

When repairing the above elements will not be enough. In particular, when replacing a section of a pipeline, sewer pipes will be needed.

There are often situations when part of the old pipe is rotten or simply cracked; in this case, it will be necessary to replace not the entire drainage system, but only a small section. In order to connect the new pipe to the existing drainage system, pipes are used.

Externally, the sewer pipe looks like a small section of pipe, on one side it is smooth, and on the other there is a socket. Accordingly, on the one hand, the connection is made using a socket method, on the other - in a joint, using a coupling.

Sometimes, when repairing an old cast-iron sewer, it is necessary to join plastic and cast-iron pipes. At the same time, to achieve the required tightness, one sealant is not enough. First, you will need to insert a rubber cuff into the cast-iron socket and then a plastic pipe into it.

Tightness of the junction of plumbing fixtures and pipelines

A sewer seal is used to reduce the likelihood of leaks in the area between the plumbing fixture and the pipeline. Externally, the cuff looks like a rubber ring that is placed over the joint.

To achieve greater elasticity, the cuffs do not contain polymers; only natural rubber is used for their production. True, during operation, because of this, it is necessary to use lubricant so that the rubber does not crack.

If you plan to use a rubber cuff, you will also need lubricant for sewer pipes. If you try to insert the end of the pipe into the cuff without lubrication, the rubber can be easily damaged. And after installation, the cuff must be periodically lubricated.

As for the specific lubricant, there are many options, some prefer to use automotive lubricant, which is used for rubber inserts in car doors in the winter. But even ordinary plumbing lubricant can keep the rubber safe and sound.

Seal dimensions

The thickness of the glass panels of the shower cabin can vary from 4 to 12 mm, respectively, the seals also have different thicknesses (usually 8-12 mm). Separately, it should be said about drippers, that is, seals that are installed on pallets. In this case, the height of the strip is 11-29 mm, so it should be selected depending on the design features of the plumbing.

Silicone seal for shower door. Length 183 cm

Silicone seal for shower door, length 200 cm, angle 45 degrees. Glass 6 mm

When choosing seals for shower cabins, you should make sure that there are no folds, cracks or other defects on the surface of the product, and that the profile of the fittings exactly fits the place where it will be installed.

What types of cuffs are there for sewer pipes?

This is predominantly a round wide o-ring, sometimes with a corrugated part. The cuffs are internal and external. Internal ones are used to connect socket structures, external ones - for smooth pipes (in addition to the seal, a coupling is installed).

Sealing cuffs with corrugated part

Cuffs are most often made of rubber - an elastic material that fits tightly, providing a reliable flexible connection. The shape of a part depends on its function.

Rubber cuffs

Eccentric cuff

The eccentric cuff consists of pipes connected to each other with an offset, that is, the centers of both parts are in different planes. Traditionally, the part is called a cuff, but this is a special shaped part for connecting to the toilet network. It is equipped with O-rings and does not require the use of sealant (with the exception of connection to an old cast-iron riser, when sealant is used for greater reliability, given the difference in materials).

Unfortunately, due to too much displacement of the connected elements, it is not always possible to use the eccentric cuff (although some craftsmen manage to insert one into the other, building a strange structure) - in such cases, the toilet is connected using a corrugation.

Eccentric cuff

The parts come in different configurations, but sometimes such a displacement is required that connection with their help is impossible - in such cases a corrugation is installed.

Pleated cuff

The corrugation is similar to an eccentric cuff, but the implementation of the displacement is different - it is achieved through a flexible corrugated sleeve, and not by positioning the parts relative to each other. Thus, the displacement can be large, but it is necessary to set the desired bending angle of the corrugated part so that the drains flow freely (otherwise blockages are inevitable).

Connection via corrugation

The main advantage of corrugation is flexibility. Thanks to this property of the part, it is almost always possible to connect a toilet to the sewer without errors. The main disadvantage is the short service life. Due to the same flexibility, the walls quickly wear out and the part becomes unusable. When choosing corrugation, you need to give preference to thick-walled, reinforced.

Reinforced corrugation

Installation is theoretically simple (the parts are simply inserted into each other according to the attached instructions), but we do not recommend installing them yourself (unless you have the skills): the cuff functions normally under certain conditions (bending angle, slope, stretch length), and if they are not created, the system will not work will be disrupted (which can lead to floods due to blockages).

So you won’t be able to read a newspaper/memoir while sitting on the toilet, looking out of the window from time to time - or you’ll have to erect a plumbing miracle on a pedestal and screw a ladder to it (here it’s not far from the attic window).

On a pedestal

There is a solution to this problem as well - installing a pumping system that forcibly sends wastewater into the sewer system. However, such drastic changes will require permission for redevelopment, and this is:

- development of a project (yes, just to move the toilet a few meters);

- payment for the project;

- its approval by the authorities and everything related to it;

- payment of the approval fee;

- the commission accepting the transfer of equipment (they look at how far they have moved away from the project, if they have moved away);

- payment of commission fees.

We recommend using the cuffs exclusively for their intended purpose - for connection and nothing more.

Everything is easy in the text - the text cannot convey the effort made. However, we all know what is transported by sewer pipes (that is, what will flood an apartment/house when incorrectly installed cuffs cause a flood), and therefore, when it comes to sewerage, we strongly recommend that you contact specialists, even those with restless hands

Especially when it comes to cast iron risers: cast iron is fragile - it must be handled with extreme caution

How to install the seal?

When purchasing a new shower cabin, a seal is usually included in the kit and is installed during the assembly process. It is placed in the joints between the glass and the frame, after which it is well coated with sealant.

Seals are supplied complete with the shower cabin

After assembling and installing the cabin, it is necessary to additionally seal it around the perimeter - in those places where its parts are adjacent to the walls. When performing work, it is recommended to follow the cabin manufacturer’s instructions, which indicate how and in what sequence it is necessary to assemble structural parts and install seals.

How to install the cuff correctly

The easiest way is to connect a corrugated pipe to a plastic riser. This is due to the specifics of such a joint: it is quite easy to insert an elastic band into the socket, after which the tip of the flexible pipes is placed in the hole.

A more complex option is to connect a plastic riser to a cast iron one. This is due to the fact that for a high-quality joint it is necessary to almost perfectly clean the cast iron socket from old residues of sealants and other possible contaminants.

It is not particularly difficult to join the sewer section of pipes with the presence of internal sealing collars.

The uncut type pipe end easily and simply penetrates into the socket area, in which the seal must first be correctly placed. When a section of the highway is cut, then at its end it is necessary to make a cone-shaped edge, after which the elastic will easily take its place. Plain water can be used as a lubricant.

Risers with a diameter of 110 mm (it is best to buy those manufactured by Rossiya) are more difficult to connect, even if you moisten the joint with water. Therefore, to facilitate the installation of the connecting collar, it must be lubricated with automobile oil and other available lubricants that will facilitate the installation process.

Similarly, it is possible to install valves for differential pressure regulators.

Since our hardware stores have a sufficient number of connecting adapter sleeves for metal, polypropylene, and plastic, it is not particularly difficult to assemble the pipeline hermetically. You just need to correctly determine the internal diameters. After this, connecting cast iron to plastic, plastic to plastic, or making any other connection will not be a problem.

Rubber cuffs for sewerage can be made from different materials, and there are also different types of devices. Hydraulic seals are used in industry, for equipping sewage systems in private houses, cottages and apartments.

Cuffs for cast iron sewers are made of polyurethane and rubber compounds such as rubber, paronite, silicone and rubber. In production, only 100% rubber is used, no polymer is mixed. Thanks to this composition, high elasticity, strength and tightness of fastening with the connected parts are ensured. Polymer and rubber also provide resistance to increases and decreases in temperature, are resistant to aggressive substances, and can be used when exposed to acids and with increased rigidity of working resources.

The sealing cuff for sewerage also comes in different types:

- rod;

- piston;

- universal (for rods and pistons).

Also, the rubber sealing cuff for sewerage can be internal or external. The internal seal is used in cast iron pipes to connect plastic pipes with different diameters. Also used to connect a corrugated hose to the drain of household plumbing fixtures (for example, connecting to the sewage system of a washing machine or dishwasher). The external seal, in turn, is used to connect to a socketless sewer structure.

There is also a three-leaf transitional sewer cuff, which facilitates the transition from a cast iron pipeline to a plastic one.

In what cases is it necessary to replace the seal?

Over time, even the highest quality and most reliable fittings become unusable and cease to fully perform their functions. If condensation begins to settle on the walls of the bathroom, and water flows out of the cabin, do not hesitate to replace the seal. Insufficient sealing of the cabin will lead to high humidity in the room all the time, and fungus and mold will appear (there is no point in fighting them, since they will appear again anyway). In order to replace fittings in a shower stall, it is not necessary to contact a specialist - you can do all the work yourself.

You can replace the seals in the shower stall yourself

How to care

The rules for caring for seals, regardless of the material from which they are made, are gentle cleaning with non-abrasive and non-aggressive detergents, as well as drying after taking a shower.

You need to check the ventilation system in the shower stall to see how well it works. If there is no good ventilation, then mold and fungus will develop on the inside of all small parts of the shower, including seals.

Sealing the shower stall is a must for those who want to enjoy water treatments at any time. By taking care of such simple things as high-quality finishing with seals, you guarantee comfort and long service life of an expensive shower installation.

Instructions for replacing the seal

To replace the shower cabin seal, you will need the appropriate fittings, a simple set of household chemicals (degreasers, solvent), as well as a special sealant, the choice of which should also be given special attention.

How to choose a sealant for a shower stall?

Sealant for shower cabin

In order for the seal to fit as tightly as possible to the structural parts, it is imperative to use a sealant during installation. There are several options for sealants that are used to treat shower enclosures. Polyurethane-based compositions are very popular today, but it is important to remember that some components can hopelessly damage an acrylic or plastic surface.

Helpful Hint: You can do a simple test before using the sealant. Apply a small amount of the composition to a regular plastic bag, then wait until it hardens. If the package becomes blistered or wrinkled, the material is not recommended for use on plexiglass or acrylic structures.

Another option is acrylic sealant, but it is not recommended to use it in wet areas. The optimal solution for shower stalls is silicone plumbing sealant. It not only seals all cracks and joints well, but also prevents the development of fungus and mold. The best composition for sealing a shower stall should contain at least 45% silicone rubber, the same amount of hydrophobic filler, a plasticizer, as well as special additives (fungicides, etc.).

Silicone Plumbing Sealant

Replacing the shower seal

In order for the seal to fully perform its functions and last as long as possible, it is necessary to correctly perform the work of replacing old or worn-out fittings.

Seal that needs replacing

Step 1. Remove the old seal. Usually this can be done by hand, but sometimes you have to use a knife (in this case the work must be done carefully so as not to scratch the cab panels).

The seal on the door glass is very easy to remove.

Step 2. The sealant on which the old seal was glued must be removed. The most effective and safe way is to use alcohol or alcohol-based solvents. The entire area to which the material is applied should be blotted with a cloth soaked in alcohol, after which it will become jelly-like and can be easily cleaned from the surface. If after this procedure yellow spots remain on the panels, they can also be easily removed with alcohol.

How to remove the seal at the junction with the walls

You can wipe the joint with the wall using an old toothbrush

Step 3. Rinse the treated surfaces well, treat with a degreaser and dry. In this case, it is unacceptable to use soap solutions, as they impair the adhesion of the fittings to the structural parts.

Wait until all surfaces are dry or dry them with a hairdryer

Step 4. First, the seal is mounted on the inside of the cabin. To avoid damaging the panels, their edges must be covered with masking tape or film.

On the left is a dismantled seal, on the right is a new one

Step 5. The places where the seal will be laid should be lubricated with a thin layer of sealant. Remove excess material immediately with a rag, otherwise it will be almost impossible to get rid of stains later.

Squeeze out the sealant, guiding it along the seam

Distribute the sealant along the seams

Step 6. Place the fittings tightly in the prepared areas and press them well to the surfaces.

The seal is placed with a drip towards the cabin so that drops of water flow into the pan

Move the seal until it takes the desired position on the glass

Step 7 . After laying the seal inside the cabin, you need to seal it outside in the same way.

Step 8. After installing the fittings along the entire perimeter of the cabin, the connections between the panels, tray, floor and bathroom walls need to be sealed again with sealant.

After the sealant has dried (the time is indicated in the instructions for the material), you need to check the tightness of the seals to the cabin parts. To do this, direct a stream of water to the joints - if it does not seep through the circuit, it means the installation was done correctly. If leaks are detected, problem areas should be cleaned again and treated with sealant.

Seal on glass door

Installation of seal

Seal installation

When assembling and installing the seals, the cabin is assembled in the proper order, in accordance with the instructions for the shower box.

To replace the seal you will need:

- degreaser;

- stationery knife or blade;

- sealant;

- seal.

Experts advise choosing sanitary silicone sealant that consists of at least 45% silicone rubber. A good option is polyurethane sealant, but it can ruin an acrylic or plastic surface.

Instructions for replacing the seal:

- The sealant is removed by hand or with a knife, being careful not to scratch the surface of the glass or plastic.

- The seal at the junction can be removed with a scraper or razor blade.

- Surfaces cleaned of sealant must be treated with a degreaser and dried.

- First, the seal is installed on the inside of the cabin. Sealant is applied to the desired areas.

- Place the seal on the desired location and press it.

- Then the sealing profile is installed outside the cabin.

- Remove excess sealant with a dry cloth.

- After installing the seal, the junction points are once again treated with sealant.

The sealant dries from 1 to 2 days, depending on the thickness of the layer. After drying, it is necessary to check the structure. To do this, a stream of water is directed at the treated joints. If liquid does not leak anywhere, it means the sealing is done well. If leaks are noticed, the leaking areas must be resealed.

A few useful tips will help you install or replace the seal more efficiently and professionally:

- Calcium deposits at the junction of the seal are cleaned off using table vinegar.

- The sealant remains in the place where the seal was. It is removed with alcohol. After processing, the composition softens and easily comes off the surface. Yellow stains are also scrubbed off in the same way.

- If the fittings are very hardened, they are heated with a hairdryer. Under the influence of high temperatures, the profile will become more elastic.

- There is no need to heat the seal or bend it during installation.

- The seal is installed first on the end of the panel, and then the rest is put on.

The drip tip should be directed towards the cabin so that the moisture flows back into the pan.

Types of seals

There are 2 types of sealers for sewer pipes:

- sealing;

- transitional.

The first option ideally seals sections of sewer systems mounted from pipes of the same internal diameters.

They, in turn, are divided into:

- internal;

- external.

The products differ only in the mounting method:

- internal sealing rubber bands can easily be placed in special socket sockets, which are also called docking extensions;

- external rubber sealing parts are put on the connecting pipe, sometimes with a clamp.

Adapter sleeves are necessary for connecting plastic risers of different diameters or for changing from one material to another: for example, from cast iron to plastic 50 or 110 mm.

In such cases, cuffs 40x20, 50x20, 50x32 are most often used. With the help of such rubber bands, you can efficiently connect drain hoses, ball valves of household appliances, appliances, devices (for example, a washing machine or dishwasher, shower stalls with bathtubs, sinks with PVC pipes, etc.).

When purchasing a plastic sewer pipe, the kit includes an internal rubber seal, the price of which is included in the total price. This type of sealant is a truncated cone, the wide end of which is inserted into the plastic. The tapered end is equipped with a hole, the diameter of which corresponds to the diameter of the corrugated drain pipe from household appliances or other household devices.

Cone-shaped rubber seal

The cast iron riser fits well with the plastic using a 124x110 cuff.

Any construction products: pipes, fittings, instruments, heating devices can always be purchased at a budget price in the Leroy Merlin network of construction hypermarkets.