What are acrylic facades?

At first glance it may seem that the panels are made of plastic. This is wrong. Thin MFD or chipboard panels are covered with special sheets of polymethacrylate, more often called acrylic.

MDF panels coated with acrylic.

This helps to ensure not only strength, which is important for furniture facades, but also wide design possibilities, as well as a characteristic glossy shine. MDF with acrylic coating is absolutely harmless, does not emit toxins when heated, and with proper care will last for many years.

High-gloss acrylic panels are easy to clean and do not fade over time. In addition, the properties of acryline help it not to absorb dirt and grease.

Bathtubs with acrylic coating

The most inexpensive are bathtubs made from a combination of ABS plastic and acrylic coating.

Here, Chinese and Turkish manufacturers turned their shoulders to the full width of the market. To the credit of the latter, it should be noted that manufacturers do not try to present their products as a counterweight to Western European brands. Acceptable quality, affordable price.

A bathtub made of a composite, with appropriate sheet thickness and high-quality reinforcement, is not inferior in strength and convenience to purely acrylic analogues.

The obvious disadvantage is the thin layer of PMMA coating. Acrylic is not scratch-resistant; it is strictly not recommended to wash it with powders and abrasives.

But if in the first options, especially considering cast acrylic, random scratches will not cause any harm to the product, then in the case of a composite, water may penetrate under the acrylic layer, which over time will lead to the appearance of blisters and microcracks.

However, if a composite acrylic bathtub is used for its intended purpose, carefully and properly cared for, it will last for many years, no worse than its more expensive counterparts.

A Scandinavian-style bathroom is a rather unusual design for Russia. You can see examples of such bathrooms in our article.

If you are still choosing a bathtub, take a look at our review of cast iron bathtubs, which presents products, both Russian and foreign.

And this article will tell you how much cast iron bathtubs weigh.

Manufacturing technology of acrylic facades for kitchens

There are two ways to manufacture such facades: one-sided and two-sided. In the first case, the acrylic sheet is glued only to the outer part, leaving the inner part untreated. In the second, both sides of MDF or chipboard are glued, providing the doors with the same appearance from the inside and outside.

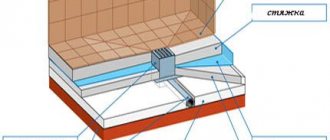

The coating is glued using a special glue (for example, Cosmofen or Akrifix), and then placed under a press. In this case, the sections are covered with a waterproof acrylic edge, which prevents peeling of the decorative layer. The thickness of such a facade often does not exceed 16-18 millimeters.

A more expensive option is solid acrylic panels up to four millimeters thick, edged with aluminum. Metal adds strength to them, comparable to chipboard, but they are much more difficult to maintain and are quite expensive.

Acrylic facade and acrylic film: what is the difference

The panels for kitchen units differ little in appearance. Both materials provide excellent gloss in almost any shade, making high-gloss beige, white, black or red kitchens increasingly common. In addition, both can imitate more sophisticated gloss options - for example, mother-of-pearl, pearl or with a chameleon effect.

But the shapes of acrylic kitchen facades and film ones differ, as do their resistance to mechanical damage and durability.

The reason is the manufacturing technology of the material.

- Film facades are produced as follows: decorative multilayer paper is impregnated with absorbent substances and then with acrylic resin. The resulting film is fixed to an MDF or chipboard panel using hot pressing. Under the influence of temperature, acrylic resin forms a smooth coating up to 1 mm thick, the strength of which is much higher than that of a plastic facade obtained by applying PVC film. But the price per linear meter is, accordingly, also higher.

The main difference of this solution is the possibility of manufacturing curved facades. It also becomes possible to cover products from the ends - postforming, which is impossible for acrylic plastic. The photo shows the design of a white kitchen.

Acrylic, or as it is also called, acrylic glass, is the result of the polymerization of methyl methacrylate. The material itself is transparent; its color is provided by the introduction of a coloring pigment into the raw material. However, furniture with acrylic fronts is made somewhat differently.

- The technology is as follows: MDF is coated with a hardener, primed and a corresponding pattern is applied to the surface in a special printer or painted. The workpiece is covered with a layer of transparent acrylic. At each stage, the plate is irradiated with ultraviolet light to better fix the dye and the plastic layer.

Since the color and pattern are provided at the MDF processing stage, and the painted surface is protected by acrylic, which is insensitive to sunlight, it is clear that such a material is absolutely resistant to fading. However, the technology eliminates the possibility of creating bent facades, so real kitchens with acrylic panels can only be of strict geometric shapes. The next photo shows an eggplant-colored kitchen set.

Furniture coated with acrylic rather than film is more expensive. The increased price is due to higher mechanical strength. The easiest way to estimate the cost is to compare it per linear meter of an acrylic wall panel and per linear meter of a laminated one. However, the first one will last at least 10–15 years, and the second one, as a rule, wears out much faster.

- Sometimes MDF boards also fall under the definition of plastic panels, where the color and gloss are provided by enamel. This is indeed a very effective solution, but its essence boils down to the use of a multi-layer paint and varnish coating, which has nothing to do with acrylic. But enamel allows you to get bent and milled facades for the kitchen. The price of such a kitchen, by the way, is even higher. Which option is better will depend on your preferences.

Pros and cons of kitchens with acrylic facades

In addition to appearance and ease of installation, such facades have a number of advantages:

- Wear resistance. The strength of acrylic reliably protects it from damage due to impacts and scratches. In addition, damaged acrylic panels can be reconstructed to their original appearance. With proper care, they will last up to 20 years.

- Acrylic does not react to temperature changes and is resistant to heating up to 160 degrees. It does not deform when exposed to water, and does not fade from sunlight.

- Grease, soot and dust are not absorbed into the surface ; it can be easily cleaned with a simple detergent and a soft cloth. We recommend: Once every three to four months, treat facades with sprays that help maintain a glossy shine, for example, Weiss or Cosmofen.

- Large selection of design solutions. Acrylic panels are presented in a wide palette. In addition, you can decorate them with prints or airbrushing or decoupage.

- The glossy structure due to its reflective properties makes the room lighter and more spacious .

- Acrylic panels, unlike plastic ones, do not release toxic impurities into the air when heated. Therefore, acrylic can be considered an environmentally friendly material.

However, it was not without its drawbacks:

- Due to the manufacturing technology, acrylic facades are quite expensive . The cost of a solid acrylic facade can reach $600 per linear meter, and an acrylic coating can cost $100. At the same time, taking into account the quality, the price can be considered relatively affordable: the long service life fully pays for the costs of manufacturing and installation.

- The glossy surface is very difficult to handle. It does not scratch or chip, but any fingerprints and dust become much more noticeable. You will have to regularly wipe away streaks and stains. Please note: Special grease-repellent polishes will help prevent the problem.

- High shine. The disadvantage is conditional, but over time many people begin to be annoyed by the glossy mirror structure of the acrylic facade.

Types of acrylic panels

Acrylic panels are divided into types depending on the base - manufacturers offer three options:

- MDF boards (MDF-acrylic).

- Gypsum boards (gypsum acrylic).

- Decoacrylic.

MDF-acrylic

This is the most common type of panel, which is explained by the properties of the base - the fibreboard made from a fine fraction of sawdust is durable, moisture-resistant and resistant to bending and deformation. Since MDF is not afraid of moisture, this type of slab is used to cover the walls of bathrooms and indoor swimming pools. Another area of application for MDF acrylic is furniture production. Most often, such facades are found on kitchen units, as they look presentable and tolerate the temperature and humidity conditions in this room well.

Gypsum acrylic

Panels with a plasterboard base are used primarily for cladding not only walls, but also ceilings in public spaces. They have also gained popularity as cladding for door and window slopes, but their use in wet areas is not recommended.

Decoacrylic

Unlike previous types, these are permeable panels with high light transmittance, but their strength is five times higher than that of glass. Visually, decoacrylic is similar to plexiglass, its surface can be matte or glossy, the panel thickness is 0.4-1.2 mm. It is used for cladding kitchen aprons, as well as creating transparent or matte decorative partitions.

With a lot of advantages, the disadvantage of acrylic walls is the cost of the panels is far from the concept of budget, especially when it comes to decoacrylic.

What is better to choose for kitchen facades: acrylic or plastic?

As mentioned above, acrylic is much more environmentally friendly than plastic. But is this the only difference? We offer a comparative table of the two materials.

| Acrylic facades. | Plastic facades. | |

| Gloss. | Clearly expressed, with a mirror shine. | Compared to acrylic, plastic is duller. There are matte options. |

| Temperature resistance. | It tolerates heating up to 160 degrees without releasing toxic impurities. | Good HPL or CPL plastic can withstand temperatures up to 140 degrees, but cheap options begin to release toxins at 80 degrees, so they should not be placed near the stove. |

| Term of use. | With proper use - up to 20 years. | After just a couple of years, it may begin to fade from heat and direct sunlight. |

| Price. | High-quality acrylic will cost you quite a lot. | Affordable price. |

| Facade type. | Only deaf. | Deaf and radius. |

Let's summarize: Acrylic facades are more durable and reliable, but the price is not encouraging. At the same time, plastic facades are more affordable, but they are more capricious in everyday use and they cannot be placed next to heat sources.

What is Acrylic?

Acrylic (polyacrylate)

Acrylic is popularly defined as polymer materials created on the basis of acrylic and methacrylic acid. That is, through chemical synthesis.

The relatively easy extraction of the material, its reliability and flexible properties have made ethers one of the most popular on the market.

Let's look at several popular meanings:

1. Plexiglas (organic/acrylic glass) - acrylic resin. This is a transparent plastic that can be painted and tinted. Formed in two ways:

Extrusion - extrusion of the molten mass.

Casting (block) - when the resin is poured between flat glasses and waits for hardening.

- Used since the 20th century as lightweight and reliable glazing parts that can withstand temperatures from -60 to +250 °C

- It is used in sports tourism, in the development of advertising materials, musical instruments, soundproofing materials and much more.

Other names: plexiglass, acrylight, acrima. Most often, names are formed from the names of popular brands.

2. Acrylic fabric

(“artificial wool”) is a high-quality synthetic material obtained from natural gas, the lightness and softness of which makes the fabric an excellent replacement for many groups of fibers and threads. It looks like wool. It appeared in the middle of the last century and was widely used:

- Manufacturing of textiles for furniture and vehicles

- Household materials: rugs, carpets, curtains

- Acrylic clothing: sweaters, T-shirts, socks, etc. Often used in winter clothing and equipment.

Other names are PAN fiber, prelana, nitron, redon, orlon, krylor.

3. Acrylic paints

- synthesis of acrylic resin, fillers and colors, soluble in water. After drying, they guarantee long-lasting color and reliable coverage for many years. These are just those paints that do not smell and are easily washed off before they dry. They are safe for adults and children!

- Used for construction and finishing works

- For artistic and decorative work

- For metals

4. Acrylic bath

- lightweight and durable products created on the basis of “sanitary acrylic” (the hardest plastic). The products are formed from simple acrylic sheets, and machines give them the required shape, melting the materials to the appropriate state.

5. TK Acrylic

— A trading company that opened its history in April 2010 in Barnaul. Specializes in wholesale and retail sales of materials for the production of advertising products, road improvement, lighting equipment, goods for the home, gardening and gardening, etc.

— It is one of the leaders in its field in the Siberian market and has several branches.

Some facts:

- All values are practically unrelated. In addition, the materials from which the products are made are based on a polymer substance.

- Acrylic is unique in all areas, and the main features are safety and durability. In the case of a company - reliability.

- All varieties may not have made a revolution, but at least a good impetus for the development of their direction.

- Plexiglas is the material and brand name of the company that patented organic glass in 1933 (invented in 1928)

- Plexiglass means “flexible glass”

- Acrylic fabric was invented in 1952 by DuPont

- Soviet chemical engineer Boris Petrovich Zverev received the Stalin Prize of the second degree in 1946 for the creation and development of the domestic organic glass industry, which was used in the production of military transparent armor

Links: ♦ Buy plexiglass ♦ Other sheet plastics ♦ We are on VKontakte ♦ Our Instagram ♦

What color should acrylic facades be made in?

The design palette for acrylic facades is extremely wide. Many colors and shades, the possibility of decorative design. We invite you to look at the most popular options among designers - perhaps you will find your ideal kitchen.

A white acrylic kitchen is a great choice for small spaces. Due to the color and glossy texture, it reflects light, visually enlarging the room and making it lighter and more spacious. However, keep in mind that such facades are very difficult to maintain - all the dirt and drops of grease are visible on the white surface, so you will have to wash the set often.

An interesting solution is a black and white acrylic kitchen . The classic combination looks very catchy thanks to the mirror shine. However, it is important to maintain a balance here: it is better if the colors are combined with each other, and do not overwhelm each other.

If such a combination seems boring to you, dilute it with another shade - it is better to choose bright colors, for example, pink, light green, blue.

Bright red is on trend right now, but we recommend being careful with it. Aggressive tones quickly tire the eyes, so monochromatic design in this case is not the best choice. Dilute it with calmer, pastel shades - beige, gray, golden.

The same applies to yellow kitchens . However, it all depends on the chosen tone. Soft colors will make the kitchen fresh and brighter, but bright colors require a muted edging.

A monochrome black kitchen is a bold but very stylish solution. It is important to pay attention to details: any inappropriate accessory, the slightest contamination - and the impression is ruined.

Choosing a surface for painting with acrylic paints

Acrylic is compatible with most materials. Dyes based on this component are used to paint on almost all surfaces: ceramics and wood, concrete bases, jewelry, dishes, even felt boots.

How to draw on wood

Paint on wood with acrylic paints.

Wood absorbs moisture well, so before applying acrylic paint to wooden surfaces, they are coated with a special primer layer. If this is not done, the image will be uneven.

If a wood product that is already painted is to be decorated, it is not necessary to prime it. And an adhesive layer is first applied to plywood blanks, which improves the adhesion of the decorative coating and makes the surface smooth.

On canvas

The most suitable base for acrylic is canvas. On this basis, the best properties of acrylic paint are revealed:

- Water resistance. Acrylic is a liquid plastic that dries to form a waterproof surface. Therefore, products painted with this product are not afraid of water.

- Transparency. This coverage indicator depends on the wishes of the master. To increase transparency, water is added to the paint.

- Mixing. To obtain the desired color, lighten or darken the tone, the dye is mixed with other paint colors.

When working with acrylic, craftsmen use a variety of painting and decorating techniques. You can experiment with this material.

Rules that must be followed when painting on canvas with acrylic dyes:

- First you need to check the condition of the paints, as they dry out quickly and become difficult to work with. Therefore, it is recommended to periodically moisten the palette with water.

- The drawing begins with drawing large details of the image onto the canvas. First, wide brushes are used with a gradual transition to thin ones. It is recommended to make the background more transparent and the details of the composition brighter.

- It is recommended to periodically wipe working brushes with a clean cloth.

- You can mix paints of different colors, add water, but not more than 20%.

On paper

Paint with acrylic paints on paper.

Not all paper is suitable for painting with acrylic paints. Some features and the dense structure of acrylic do not allow the use of smooth and thin paper sheets as a base.

It is recommended to paint with acrylic-based dyes on cardboard or embossed thick paper.

To design wall surfaces, craftsmen often use the technique of artistic acrylic painting. The chemical characteristics of acrylic coating allow it to be used for painting on wallpaper.

On glass or ceramics

Paints that are suitable for painting on glass are divided into 2 categories: acetone and glossy.

For large-scale decorative works, dyes made from acetone are used. Such paints spread well and are distinguished by bright, stable shades. Pictures on glass decorate not only residential but also office premises. After the image has dried on the glass, the surface can be washed with a damp cloth.

There are universal acrylic acetone paints for finishing glass objects. They are suitable for painting on ceramics, polystyrene, plexiglass, earthenware, and other types of plastic. These are moisture-resistant coatings that retain their original brightness and contrast for a long period. They combine well with other materials. But such dyes are prohibited from being used to decorate food utensils.

Glossy paints crystallize at normal temperatures. Before use, you can mix dyes of different colors. After applying the first layer of the composition, the workpiece must be allowed to dry for 2 days. Then you can apply a second layer and protective varnish.

Painting on fabric

Paint with acrylic paints on fabric.

Acrylic is widely used for decorating fabric materials. But before you paint clothes, you need to take into account the structure of the material from which it is made.

Natural materials treated with synthetic dye are well tolerated by frequent washing. They are more resistant to mechanical stress in contrast to synthetics.

To draw on fabric items, you need to use a stencil or do step-by-step painting of individual elements.

If you have no experience in decorating clothes with acrylic paints, it is better to practice on an unnecessary piece of fabric. This will allow you to choose the right dye density and brush size.

Drawing on skin

One of the most popular types of needlework is leather painting. In this way, craftsmen give old leather items new life.

Scope of application of leather painting techniques with acrylic paints:

- wallets and bags;

- clothing and shoes;

- furniture;

- easel works;

- making mosaics, etc.

Acrylic adheres to leather surfaces just as well as oil. It penetrates into all the cracks of the base and covers it with an even layer.

Skin parameters to consider when applying acrylic paintings:

- Smoothness. Paint consumption is less when working with smooth surfaces, and the image lies more evenly than on rough substrates.

- Softness. The softer the skin, the thinner the coating.

- Material processing option. Two similar workpieces may differ in the quality of processing. Therefore, the sample is first checked for the possibility of deformation after coating with acrylic.

- Thickness. The thicker the material, the more layers of dye can be applied to it, but it is more difficult to work with.

- Color. The original colors of the material, especially with a rough surface, after painting with light compounds can appear on the surface in the form of color spots.

Thin, smooth leather with a fine texture lends itself best to painting. Material with a large texture can shrink after painting, so it is more difficult to work with it; you need to have experience.

Painting on nails

Manicurists also use acrylic in their work. They were attracted by this material due to its characteristics: vapor tightness and water resistance. Acrylic paints allow you to expand your nail painting options.

One tube of this product can be used simultaneously to apply a base coat, as a modeling paste and as a translucent toner. In this case, acrylic-based dyes can be mixed with solid particles (modulators and glitter).

Acrylic paints can be used to paint on nails that have previously been coated with gel polish. At the same time, artistic dyes do not pose a health hazard.

Manufacturers of acrylic kitchen facades

Acrylic panels are produced by dozens of manufacturers with very different pricing policies.

We offer you the TOP 3 manufacturers popular in Russia:

- Bel Viso using NIEMANN panels. Polish acrylic facades are one of the most famous. A wide selection of decorative designs, a huge color palette and high quality. The price, however, is appropriate - from $150 per linear meter.

- The Sidak company , located in the Leningrad region, will also not please you with the price tag - from $140 per meter. However, the factory goes through the full production cycle: from the panel to the finished facade, which affects the quality.

- Fordom is a more budget option. Turkish facades will cost you an average of $90 per meter. Of course, you can also find cheap acrylic facades. But be careful - most often the tempting price tag hides a low-quality coating or simple plastic, sometimes not even heat-resistant.

Types of facades

As is clear from the manufacturing method, the MDF board is lined with the material, and not covered on all sides. The cladding can be one-sided or two-sided. If a light color is chosen for the headset, then one-sided finishing does not affect the appearance. But if the color chosen is eggplant, black and white or blue, then the door of different shades from the outside and inside does not look aesthetically pleasing.

The design of the kitchen set is also influenced by the finishing of the ends: with an edge, postforming or in an aluminum frame.

- Postforming - an option available only when using acrylic film. The panels are covered with material on both sides, simultaneously capturing 2 edges - this is postforming. The ends of the slab are rounded, and their upper and lower edges are sealed with a PVC edge. Postforming provides greater durability as it reduces the number of joints. The photo below shows panels obtained using postforming.

- Edge finishing – the headset panels are lined with PVC or acrylic edges on all sides. Acrylic is more durable and wear-resistant, but it increases the price per linear meter of the kitchen slightly.

- Panels in an aluminum frame - this option is better in terms of strength. The façade in an aluminum frame does not deform and is not subject to abrasion. This design is extremely attractive for techno, hi-tech or constructivism styles. The disadvantages of the solution are that the ends will have to be cleaned more often, since metal gets dirty faster than acrylic film. The photo shows a black and white panel in an aluminum frame.

A facade in an aluminum frame, no matter what the reviews say, is not suitable for glazing, since it has completely different characteristics. If you need to make the door transparent, you need to order a door made of acrylic glass.

A kitchen set with acrylic panels offers an exceptional variety of color and shine: black and white or beige pearl gloss kitchen, eggplant combined with green or mint color and so on. In addition, you can add individuality to furniture through photo printing. However, the shape of the panels will remain unchanged - only rectangular contours.

Reviews from real owners of acrylic kitchens

If you look at the reviews of people who bought acrylic facades for their kitchen, you will notice one common point - everyone admires their beauty and durability, but emphasizes the capriciousness of their care. Most often, this means the need for regular cleaning.

However, some people think that wiping the facade once a month is enough, but the only disadvantage is the cost.

And some people don’t like the need to use special care products.

Sometimes a change in shade depending on the lighting is noted. Therefore, be careful with pastel colors - in the twilight they may appear dull.

However, the reviews are unanimous on one thing - acrylic facades are reliable, durable and beautiful.

How to care for acrylic facades

As can be seen from the reviews, the main problem with acrylic facades is their maintenance. How to properly care for the panels?

Now we'll tell you:

- Do not use aggressive abrasive detergents.

- When choosing what to wash the panel with, stick to the mildest possible detergents - for example, regular dishwashing detergent.

- Use lint-free soft cloths.

- Wipe the surface regularly to prevent fingerprints and dirt from accumulating on it.

- Use polish for acrylic kitchen facades - it will make cleaning much easier.

Let's summarize: With proper care, an acrylic facade is an excellent choice for kitchen design. A beautiful, eco-friendly and durable set will become a real decoration of the room. Among the disadvantages, we note the high price - however, taking into account the durability of such furniture, it is completely justified.

House projects with painting

Number of projects 453

- 6 rooms

- 4 bathrooms

Duplex House Project

- To favorites

- 215² Total area

- 8 x 16m Construction area

from 3,037,700 rub.

Construction period 60 days

- 3 rooms

- 2 bathrooms

Bogachevo House Project

- To favorites

- 100² Total area

- 10 x 6m Construction area

from 1,350,000 rub.

Construction time individually

- 10 rooms

- 4 bathrooms

House Project Tula Gingerbread-2

- To favorites

- 366.6² Total area

from 4,949,100 rub.

Construction period 169 days

- 2 rooms

- 1 bathroom

Country house project Dacha 13

- To favorites

- 36² Total area

- 6 x 6m Construction area

from 314,300 rub.

Construction time individually

- 5 rooms

- 3 bathrooms

Ruslan's House Project

- To favorites

- 285.2² Total area

- 14 x 23m Construction area

from 3,850,200 rub.

Construction period 146 days

- 5 rooms

- 2 bathrooms

Silvius House Project

- To favorites

- 381² Total area

- 16 x 16m Construction area

from 5,143,500 rub.

Construction period 155 days

- 2 rooms

- 1 bathroom

Country house project Dacha M2

- To favorites

- 63² Total area

- 6 x 6m Construction area

from 360,000 rub.

Construction period 14 days

- 4 rooms

- 3 bathrooms

Da Vinci House Project

- To favorites

- 234.3² Total area

- 11 x 17m Construction area

from 3,163,050 rub.

Construction period 123 days

- 6 rooms

- 3 bathrooms

House Project 29-202

- To favorites

- 207² Total area

from 2,794,500 rub.

Construction time individually

- 4 rooms

- 2 bathrooms

Scandinavian House Project

- To favorites

- 116.11² Total area

- 10 x 10m Construction area

from RUB 1,567,485

Construction time 83 days

- 3 rooms

- 1 bathroom

Bergen House Project - Alpha

- To favorites

- 82² Total area

- 11 x 8m Construction area

from 1,990,000 rub.

Construction period 45 days

- 2 rooms

- 1 bathroom

Irish House Project

- To favorites

- 73.29² Total area

- 6 x 8m Construction area

from RUR 989,415

Construction period 70 days

- 3 rooms

Country house project Dacha M3

- To favorites

- 88² Total area

- 6 x 8m Construction area

from 355,000 rub.

Construction period 14 days

- 5 rooms

- 2 bathrooms

House project "4516"

- To favorites

- 158.4² Total area

- 10 x 11m Construction area

from RUB 1,645,350

Construction period 30 days

- 5 rooms

- 3 bathrooms

Patrinia House Project

- To favorites

- 216.8² Total area

- 17 x 14m Construction area

from RUR 2,926,800

Construction period 120 days

- 3 rooms

- 2 bathrooms

House Project Candle-5

- To favorites

- 77² Total area

- 6 x 6m Construction area

from 1,039,500 rub.

Construction time 73 days

- 4 rooms

- 2 bathrooms

Nobis House Project

- To favorites

- 217² Total area

- 17 x 11m Construction area

from 2,929,500 rub.

Construction period 119 days

- 2 rooms

- 1 bathroom

House Project 4-95

- To favorites

- 95² Total area

- 13 x 7m Construction area

from 1,282,500 rub.

Construction time individually

- 4 rooms

- 3 bathrooms

Ivolga House Project

- To favorites

- 229.7² Total area

- 13 x 11m Construction area

from RUR 3,100,950

Construction period 123 days

- 2 bathrooms

Volochanovo House Project

- To favorites

- 165² Total area

- 12 x 9m Construction area

from 2,227,500 rub.

Construction period 84 days

View all projects

Let's talk about why acrylic paint is so popular today, what features it has, and what you need to know to choose a material to perform various construction works. We will talk about the advantages and disadvantages of acrylic-based paints, and reveal the features of the technology for working with them.

Acrylic paints for construction work Source interier-vyksa.ru