During use, from time to time unforeseen situations arise that cause damage to certain structural elements, and if the repair of the partition involves replacing the damaged element, then the question of what to do if the shower tray bursts can be resolved in different ways. Let’s make a reservation right away: for products made of ceramics and metal, the only solution is replacement, but you can try to repair acrylic structures yourself; we will consider this option in the article.

How to repair a shower tray

During the operation of the equipment, a variety of defects can occur in the pallet: from very small cracks to deep scratches. Each case requires a specific approach. In addition, before repairing, you need to remember that the better you perform it, the longer the equipment will last.

Repairing minor flaws

If you notice a small, barely noticeable crack on the surface of the bowl, then you need to correct the situation immediately, since even such minor damage can lead to more global problems.

Restoring the coating in this case looks like this:

- carefully and slowly clean the edges of the scratch with a sharp knife;

- remove dust from the area with a damp sponge;

- wipe the area with alcohol or any other product with a degreasing effect;

- put on safety glasses, a gauze bandage, rubber gloves and dilute the acrylic mixture according to the instructions;

- Apply the composition to the damage with a small brush or broom until it is completely filled with paint, and the layer protrudes slightly above the level of the bowl’s coating;

- wait for the composition to dry completely, and then clean off the excess using sandpaper.

Finally, a layer of polish is applied to the area.

Repair of deep cracks

If the damage is more significant, or even extends along the entire pallet, then painting will definitely not help. Here we need more drastic measures to restore the surface:

- Remove the pan completely. To do this, first turn off the water supply and disconnect all connected communications. If, while unscrewing the nuts, you find that they are difficult to remove, lubricate them with silicone-based lubricant: this will greatly facilitate the dismantling process.

- Wash the bowl thoroughly on all sides and wipe dry.

- Remove all debris and plaque inside the crack, and thus completely expand the damaged area.

- Use sandpaper to clean the outer and inner bottom.

- Remove dust again and degrease the surfaces.

- Using epoxy glue, apply a layer to the back of the bowl. Repeat the procedure several times. In this case, the layers should alternate: glue-fiberglass-glue-fiberglass and so on 3-4 times depending on the size of the defect.

- The inside of the pallet is processed a little differently. First you need to completely fill the chip with epoxy glue. To fill the crack as tightly as possible, use a rubber spatula. Next, the composition must dry completely.

- Sand off the excess and cover the bottom with acrylic paint.

- After the acrylic has dried, polish the bottom.

- Connect all pipes.

After performing such repairs, you will not only add strength to the bowl, but also extend the life of all equipment.

Sealing through holes

In fact, repairing through cracks is practically no different from repairing deep cracks. But in this case, you will need some kind of durable patch. Sealing holes is done as follows:

- The pallet is similarly completely dismantled, cleaned, and degreased.

- A patch is applied to the inside of the bowl. The same epoxy glue and fiberglass can act as it.

- Prepare epoxy glue according to the manufacturer's instructions and fill the gap with it so that it rises slightly above the bottom. In order for the glue to fill the hole as tightly as possible, it needs to be pierced with something long and sharp. For example, with wire or even a knitting needle.

- Apply another patch on top of the hole.

- Paint the completely dry patch with acrylic paint.

Repairing a through hole is only advisable if its size is less than 10 cm. Otherwise, this will not lead to results, since such damage has already lost its integrity and strength and it is better to replace the bowl with a new one.

Sealing through holes

In cases where heavy objects with sharp edges have fallen into the bowl and a through hole has formed in it, you will have to act as follows:

- first, the damaged product is carefully removed from the pedestal (base), and then thoroughly washed and dried;

- the area of the hole or chip is degreased with alcohol on both sides;

- a fiberglass patch is applied to the back surface with epoxy glue, the main purpose of which is to hold the sealant that fills the hole (it is better to glue it in 2-3 layers);

- After the patch has dried, a ready-made epoxy compound is poured into the through hole so that it protrudes slightly above the outer surface.

Finally, another fiberglass patch is applied over the hole covered with glue, and then (after it dries) the repaired area is painted over with acrylic dye.

Important! Holes can be sealed when their size does not exceed 10 cm.

For large holes, experts do not recommend trying to fix the hole in this way. In this case, the structure loses its strength and requires complete replacement; no repair will help.

Operating Instructions

Follow the step-by-step instructions.

Light damage

If the pallet is slightly cracked, but no noticeable damage appears, it is recommended to immediately repair the crack. Otherwise, it will begin to spread and cause big problems. Step-by-step algorithm of actions in this case:

- Remove moisture from the tray, wipe off the liquid with a clean rag and let it dry - if there are minimal cracks, there is no need to remove it.

- Wipe the area of the crack and the crack itself with a cotton swab dipped in alcohol.

- Apply regular acrylic glue.

- Allow to dry for required time.

- Apply a second layer.

A minimum amount of glue must be applied at each stage, in a several millimeter layer. In this case, it is better to let the composition sit for at least a day, and only after that apply the second and third layers. To polish the surface, if traces of the composition are noticeable on it, you can use fine sandpaper. But you shouldn’t try too hard - sandpaper can cause new scratches, which will lead to a crack.

Deep damage

Gluing a pallet if the damage is deep is not as easy as it seems at first glance. You will need:

- Dismantle the plumbing fixture.

- Treat two surfaces with a cotton swab soaked in ethyl alcohol.

- Apply a brush with glue to the most remote places.

- Gradually leveling the plane, ensure that the distance between the edges is the same on all sides.

- Fill the crack with adhesive.

The rule also applies here: you need to apply less glue, but leave it on longer. It will be great if a person who repairs a pallet with his own hands can not use it for at least one week.

Do-it-yourself elimination of through holes

Repairing a pallet if a through hole appears on it is the most difficult thing. But with the right amount of persistence, it can be done. You will need:

- Dismantle the pallet, removing all accessories that could be damaged if dropped or hit.

- Using a sander or drill, remove the chamfer to create a sharpened edge.

- Wipe until clean from dust and dirt, use a cloth with alcohol to remove grease.

- Cut patches from fiberglass or acrylic.

- Impregnate the parts with resin.

- Apply them to the previously cleaned edges.

- Turn the pan over and fill the crack.

Of course, if there is a through hole, the tray cannot be used. Even with service repairs, it is not always possible to achieve positive results. Therefore, in many cases it will be easier to buy a new pallet, if it is not expensive, than to engage in lengthy and expensive repairs of the old one.

Sealing process

You can work right on the spot (the glue is not as harmful to the body as the compounds mentioned above), but it is better to wear a respirator.

At the beginning of the work, you need to remove the stress from the damage: drill a small hole at the extreme point of the breakdown. No need for pass-through. 2-3 mm from the surface is enough. To prevent the scratch from going further, make 2 indentations along the edges. Choose a drill slightly larger than the width of the crack;

Use a file or sandpaper to sand the edge of the break so that it becomes smooth. For larger through-hole damage, a cylindrical grinder and plastic disc are recommended.

When reinforcement of the lower part is required in case of through cracks, the bottom must be covered with fiberglass impregnated with epoxy resin. Preferably in several layers. Each layer must dry for at least 24 hours.

Wash away all contaminants in the area where you will work and cover with a degreaser. Use an alcohol solution, as acetone or petroleum products will damage the surface. This preparation will enhance the properties of the glue;

Place a small piece of fiberglass into the crack. Apply one layer of glue on top with a spatula. A thick layer will not dry out in a day, so apply glue, carefully removing all excess. Do the same on the other side.

Before putting the pallet back, cover the crack under the bottom with foam. The damaged area will become more stable, and the crack will not go further.

Mixture for repairing acrylic products

When the shower tray is completely cracked, you can learn how to glue it together using a special mixture from the instructions included with the product. The mixture contains hardeners and liquefied acrylic. It needs to be prepared before pouring.

Related article: Shower drain in the floor

All cracks are filled with the mixture. It’s not scary if it ends up with excess, since the liquid will evaporate when it dries. The excess can then be removed using a rubber spatula.

The pan in the area of the crack must be covered with tape and left for a day so that everything is completely dry.

When the surface is dry, it should be treated with fine sandpaper.

The work is finished, you can install the bottom, assemble the cabin and check the seams for leaks.

Preparing the cabin for pallet installation

During the process, you need to be careful not to spill the mixture on the floor - it is difficult to clean up. But you don’t have to worry about the quality of the repair; the acrylic coating is practical and will last you a long time.

Causes of defects in pallets

On the domestic market there is a large assortment of shower cabins with trays, for which a mandatory warranty is issued upon sale. But in some cases, these obligations are unable to protect products from accidental breakdowns, which most often occur for the following reasons.

A manufacturing defect discovered during operation, consisting of voids in the pallet body or a violation of the geometry. In this situation, it would be most reasonable to try to exchange the defective product for a quality product.

Installation errors, which consist in incorrectly preparing the base for the shower stall when it is not leveled enough. Such a malfunction leads to unwanted deformations and gradual destruction of the overstressed material (under heavy loads it can simply burst).

Violation of the rules for handling a shower stall, which requires careful handling.

Small cracks form on the body of a plastic or acrylic pallet due to unacceptable loads when several people (an adult and a child, for example) walk on it at once.

In addition, serious damage occurs to work surfaces when heavy objects with sharp edges are dropped onto them. If the pallet unexpectedly cracks for one of the reasons listed above, first of all you should figure out how large the detected defect is, and only then proceed with repairs, if possible.

Broken door rollers - repair methods

Rollers, as many people mistakenly think, are a completely simple part in a shower stall, but it is they that bear the heaviest load during operation. If the rollers squeak or the cabin doors suddenly begin to jam, you should seriously think about replacing them.

Such small parts require certain knowledge when carrying out DIY repairs. So, pay special attention to the diameter of the wheels . The difference in size can be no more than 5 mm; it is also worth taking into account the width of the groove, the distance at which the door moves inward.

The highest quality shower rollers are made of stainless steel or brass . Replace the rollers in the following order:

- dismantle the doors;

- remove the rollers using pliers and a Phillips screwdriver;

- install new parts and tighten the nuts for fixation;

- start installing doors;

- adjust the rollers, the tightness of the fit of the sashes and the ease of their sliding along the guides depends on this.

To protect yourself from similar problems in the future, be sure to treat the wheels with an anti-corrosion agent . Then, even if a large amount of water gets on them, they will not rust.

In the cabin, almost all metal parts that make up the structure are susceptible to severe corrosion. To eliminate the rust that has appeared, you need to thoroughly sand the area that is affected by rust, then treat it with auto putty , clean the treated area, and degrease the surface.

Ammonia or acetone are perfect for this. Then you need to paint the existing damage with special spray paint.

How to repair a pallet

During the operation of shower cabins, small and deep cracks, chips and holes may form in their bowls. Each case requires a different troubleshooting approach. Repairs must be carried out in such a way as not to redo the work done after a short period of time. Let's consider the list of measures that are carried out when eliminating various types of damage in the shower bowl.

This is the most common malfunction that occurs on shower trays. If you repair the crack right away, the destruction of the bowl will end there.

Small crack on the pallet

Such work must be done in the following sequence:

- Use a sharp knife to clear the edges of the crack. You need to scrape off the acrylic until the scratch walls return to their original color.

- Remove accumulated dust using a vacuum cleaner. Wipe the treated material with ethyl alcohol.

- Wear goggles, a respirator and gloves. Prepare acrylic paint for use.

- Using a brush, apply acrylic paint to the scratch. Depending on its depth, repeat the procedure several times until the paint level exceeds the level of the bottom of the bowl.

- After the paint has completely dried, smooth out all the sagging with sandpaper, gradually reducing its grain size.

If the damage is deep, it can quickly destroy the entire bowl, rapidly increasing in size. If the product has burst throughout its entire volume, then painting is not enough. More effective measures need to be taken.

deep crack

Here's what to do:

- Remove the bowl. To do this, you will need to turn off the water and disconnect all communications from the shower stall. If the bolts and nuts are rusty, they must be treated with silicone grease. This will make the process of unscrewing them much easier.

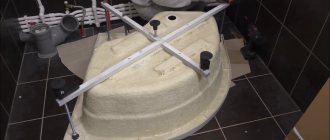

Removing the pallet

- Clean the tray from both sides of dirt, limescale and mold. Wash it thoroughly with soapy water, rinse with clean water and wipe dry.

- Expand the gap by removing plaque, dirt and fragile material from its walls that has split down to fibers. If there is such a need, then you need to make a through hole.

- Clean the bottom and working part of the container with sandpaper. The surface must be treated with a margin of 5 cm on all sides. Remove dust, degrease acrylic with medical alcohol.

- Mix epoxy glue and apply it to the back of the bowl, focusing on the areas cleaned with sandpaper. Press regular gauze or fiberglass tightly onto the epoxy glue. Repeat the process 3-4 times depending on the size of the gap.

- From the front side, fill the gap with epoxy glue. Wait a day until it completely hardens. Sand the glue with sandpaper and cover it with several layers of acrylic paint.

- Grind and polish the front surface. Install the product in place, connect the communications, check the functionality of the drain.

After such repairs, the pallet will become stronger than at the time of sale. Its service life will increase significantly.

Shower tray

Repair of holes should be carried out in the following sequence:

- Remove the container from the base. This must be done very carefully so as not to damage its edges or split it. Clean the bowl from all types of dirt, wash and dry.

- Clean the edges of the hole from all contaminants. Remove protruding fibers and weak fragments. Degrease acrylic with medical alcohol.

- Apply a strong patch to the inner surface of the pallet, which is necessary to fix the filler and seal it. For this, epoxy glue and several layers of any durable material are used. It is best to use fiberglass, which is intended specifically for such purposes.

- Prepare epoxy glue according to the included instructions. Pour it into the hole so that it protrudes slightly above the surface of the bottom of the pan. To avoid voids in the epoxy filler, the resin must be pierced with wire in several places.

- Place another patch over the hole filled with glue. For this, epoxy glue and thin fiberglass are used. After drying, paint over the patch with acrylic paint.

Preventing pallet damage

If you follow the rules for installing and operating a shower cabin, its service life can be counted in decades. But it is not recommended to use it with a weight exceeding the permissible one (jumping on a pallet, taking a shower together with a child).

Metal watering cans should be handled carefully. When dropped, it causes cracks and chips. The bowl should be cleaned with soap or alcohol solutions that do not damage the acrylic.

Preventive measures include regular inspection of the structure to detect minor deformations. Early detection of a malfunction facilitates the subsequent restoration process and reduces repair costs.

Main types of breakdowns and their elimination

The most common type of damage to a shower tray is cracks. Depending on the degree of their depth, cracks are:

- through (holes);

- small superficial (no more than 35 cm in length and an area not exceeding 100×100 mm);

- a network of small cracks (scratches).

Causes

The main causes of cracks are:

- Incorrect installation. If during installation of the pallet the technology was violated, for example, the pallet was not leveled horizontally or the fastenings were not tightened tightly enough, then during its operation the load will be distributed unevenly, which can lead to the formation of cracks.

- Initial manufacturing defects of the product. This is a rather rare case, but sometimes before purchasing it is impossible to determine the presence of hidden internal flaws that can only appear during operation. But usually they are detected much earlier than the warranty period expires, so it is not worth repairing such a pallet.

- Carelessness during operation. The most common reason. When relatively cheap models of Chinese-made shower trays are used in the shower, sometimes it is enough to simply drop the shower head from your hands to cause a crack to form.

Step-by-step repair instructions

The specific steps to eliminate cracks directly depend on the type of crack. In general, in order to repair almost any cracked pallet on your own, you need to have the following materials and tools:

- ethanol;

- hardener;

- sandpaper;

- acrylic paint;

- epoxy resin;

- acrylic liner or fiberglass;

- stationery tape;

- liquid acrylic;

- brush;

- medium-sized rubber spatula;

- drill with a special attachment for polishing;

- angle grinder.

Many models of shower cabins come with a repair kit to repair cracks in the pan. Therefore, a number of the materials listed above can not be purchased separately, but can be used from this kit.

The simplest case is when the crack on the pallet is very small and runs only along its surface.

To eliminate it, you don’t even need to remove the product; you just need to dry it before repairing.

Using a brush, you need to cover the entire surface of the crack with acrylic paint in several layers and let it dry for 24 hours.

The process of repairing deep cracks and holes looks a little more complicated. In this case it is necessary:

- Dismantle the pallet if the damage is in a hard-to-reach place or if it is through.

- Use a grinder to widen the crack, making a chamfer along its broken edges.

- Clean the seam from all kinds of contaminants by rinsing it with water and degreasing it with ethyl alcohol. Under no circumstances should you use aggressive detergents for cleaning.

- Mix liquid acrylic with hardener in appropriate proportions according to the instructions.

- Apply the resulting mixture to the damaged area of the pallet using a plastic or rubber spatula in generous quantities so that it completely fills the crack. Then remove any excess acrylic that appears.

- If the crack is through, then on the reverse side, which has also been previously cleaned and degreased, patches made of an acrylic liner or fiberglass should be applied, generously soaked in epoxy resin.

- Seal the crack with tape and let the compound dry. This usually takes from 1 hour to a day (the duration depends on the composition of the specific repair kit).

- After the composition has dried, peel off the tape and sand the surface of the tray with sandpaper or an electric drill with a special attachment.

Regardless of the complexity of the work, all of it must be carried out in a well-ventilated area, since the materials used in the process (acrylic paint, epoxy resin, hardener) in a liquid state are harmful to the health of humans and pets.

Types of cracks

Before repairing a crack in a pan, experts advise correctly assessing it according to the generally accepted classification. In this case, three types are distinguished, namely: small cracks barely visible to the eye, deep potholes and through holes.

Each of these damages requires individual consideration, since the complexity of the upcoming repair depends on the correctness of their assessment.

So, if it is enough to cover a small crack with a suitable hermetic mixture, then to eliminate more serious violations in the shower tray, a completely different approach will be required.

In the second case, cosmetic repairs alone will no longer be enough. If large chips and through cracks are detected, serious restoration work is necessary.

Best answers

White and fluffy))):

sealant

Count de Wall:

Your case is almost rotten - the plastic sticks very poorly. The sealant will not stick to the surface. You can try cyanoacrylate instant adhesives (small tubes like that...), but the surface needs to be thoroughly cleaned with acetone before work. And don’t breathe - the glue is poisonous. The crack will stick together, but The glue itself is not waterproof, so everything depends on the quality of pressing the walls of the crack against each other. In general... I would paint it with green paint and throw it away. If there is such a possibility...))))))))))))))))))))))))))))))))

RA1ABN:

If a person stands on the pallet, then no amount of gluing will help - it’s useless. We cannot see here where this crack is and why it formed. You can temporarily seal it with tape while you buy a new pallet.

Chairman:

The commentators are right: the matter is rotten, since the pallet will move under the weight of a person, and NO glue will withstand this, since the thickness of the surfaces being glued is SMALL. The only thing that can save you is to install a SUPPORT under the crack from the bottom of the pallet in order to relieve the load. Then you can merge it.

Belogurov Nikolay:

throw it all away, or something extraordinary

galino4kas galino4kas:

What if you try to fill it with pool solution?! Fill the entire surface of the pan! Good luck (Sales consultants can help)

Alexey Pastukhov:

Dorofeev is right... you need to remove the load from the pallet and then glue it or weld it with a soldering iron, it’s up to you…. the weight will crush all efforts...

Marmelad- Marmelad:

You can cover it with water-repellent sealant for the first time, and soon buy a new pallet. If you have large people in your family, you can install a metal one.

Rest.:

Acrylic... Here I encountered a similar problem. The options (and they exist - Materials for repairing yachts, etc..) turned out to be so time-consuming and expensive - it's easier to use a new one... Or by unloading the pallet, as correctly noted in previous posts... (that's actually why it cracked) Make an applique on the crack from fabric with epoxy glue... Or you can spend 2-3 days completely gluing it from fabric with epoxy resin... Sand it, prime it, paint it like new...

Mikola:

Try cutting another hole in this place for the drain fittings and installing it. The fittings can be connected to the sewer or plugged.

Anar Darkesheva:

I have a crack in my pan. Using the shower stall for 12 years. And they said that they were Chinese for 3 years... Maybe my cabin is Polish, I don’t know... The whole set needs to be changed. And the tiles too. Everything is glued to the wall. I'm afraid that during dismantling the tile will come off the wall... I've been living in this apartment for 12 years... I'll have to temporarily repair the crack until we get a new one... Let's think...

kostilka:

1. Make a support in the place of the crack, thereby removing the load from this place2. Buy fiberglass + epoxy glue. Seal the crack

Alexey Petrov:

pavilion epoxy glue

Anatoly Kichigin:

Carrying out repairs

When applying the composition, the technician must wear a mask and gloves.

Before you undertake to repair the surface of the pallet yourself, you need to determine the feasibility of this action. A large number of cracks and their rather large depth may indicate that it is better to replace this element of the cabin completely. After all, constant repairs will not lead to the desired result.

It is advisable to order a new pallet from the same company that made it previously, so that the fastening parts of the cabin and the pallet match.

It is advisable to perform all work that involves applying liquid acrylic outdoors or in a well-ventilated room. This will avoid toxic poisoning of the body.

When purchasing a shower cabin, you should inquire about the availability of a repair kit for the shower tray, as well as all instructions for installation and dismantling, and operating features. All manufacturer’s recommendations given for further use must be followed in full so that the integrity of the pallet is not compromised for as long as possible.

Requirements for work

It is extremely important to follow a couple of basic recommendations, since any violations will lead to a worsening of the final result; they are quite simple, but they are worth knowing:

| Careful preparation | It is fundamentally important to stock up on everything you need so that during the repair you do not have to be distracted or use improvised devices that are not very suitable for this type of work. You must ensure that the work area is prepared and all required items are on hand. |

| Material quality level | In addition, a perfectly organized technological process will not produce results if you use low-quality repair compounds. Based on this, you should not save when purchasing, since a low price is much more often an indicator of low reliability. |

| Following the process | The instructions that come with the repair composition must be studied most carefully; any violation of the proportions is unacceptable. In addition, it is fundamentally important to adhere to all agreed terms; if it is written not to touch the element for 24 hours upon completion of application, then work should not continue after 12 hours, in addition, if the surface seems to be completely frozen. |

| Application of protective equipment | Much more often chemical compounds are used, which can cause harm to health if personal protective equipment in the form of gloves and a respirator is not used. The ideal option is to carry out repairs outdoors, so you are guaranteed to avoid inhaling harmful fumes. |

Advice! In addition, if the damage is minor, we recommend removing the shower tray, this way you will prevent accidental damage and will be able to closely inspect the structure; cracks on the inside are also likely, but they can only be noticed after dismantling the element.

How to seal a shower tray - choice of glue

Modern shower cabins use trays made of acrylic (white plastic). This is a fairly durable and “warm” material, it is not afraid of moisture, however, under the influence of excessive load, acrylic can bend and crack. The acrylic surface can also be damaged by falling heavy objects.

If the crack is large, the best solution would be to completely replace the pan (they have standard sizes and are sold separately). Minor damage can be repaired at home.

It should be taken into account that acrylic has poor adhesion and special glue is required to glue it. It is also necessary to take into account that the restored surface will continue to be subject to stress, as well as the aggressive effects of moisture and detergents.

For quick repairs of deep scratches, chips and small cracks on the front side of the tray, a ready-made universal repair kit for acrylic bathtubs is suitable.

The kit is sold in plumbing stores and usually includes:

- solvent;

- liquid acrylic;

- hardener for acrylic;

- paste for polishing and giving the restored surface gloss;

- polishing cloth

- gloves, a stick for mixing components.

On sale you can find repair kits from various, “New Bath”, etc.)

To eliminate through cracks and holes on the back side of the pallet, it is necessary to glue a patch.

For it you additionally need to prepare:

- fiberglass sheets;

- EDP (epoxy glue);

- small spatula for applying glue.

Universal two-component EDP adhesive is sold as a mixing kit (epoxy resin + hardener).

EDP brand adhesive is made on the basis of epoxy resin, which is insensitive to moisture and other irritants. If you follow the proportions specified in the instructions, you don’t have to worry about the durability of the adhesive seam: the glued area will not be inferior in strength to the materials being joined.

EAF is the most affordable epoxy adhesive (a set of two components costs about 150 rubles), it also has more expensive imported analogues.

For example, Plexus MA 420 fiberglass adhesive, which is ideal for gluing composite materials and requires virtually no preliminary surface preparation. Its only drawback is its high cost (about 2,400 rubles per package).

Sealing cracks in an acrylic shower tray - step-by-step instructions

To repair an acrylic shower tray, you need to have easy access to its front and back sides. To do this, the cabin will have to be disassembled.

The order of further actions is as follows:

- We exclude further propagation of the crack. To do this, remove the tension from the zone of its formation. A few millimeters from the edges of the crack, you need to use a drill and drill to drill through holes of small diameter (3-5 mm);

- We glue the patch to the back of the crack. You must first remove dirt and degrease the surface to be restored. We cut out several patches of suitable size from fiberglass, which must be glued in several layers to achieve maximum joint strength.

Since the glue hardens almost instantly, you should act immediately. The resin is applied with a brush to the cleaned surface in generous quantities and covered with fiberglass. After the first layer has dried, the second and third layers are applied in a similar way. When the patch has completely set, the pallet is turned over and they begin to seal the crack from the front side.

- We fill the crack with liquid acrylic and polish it. In accordance with the manufacturer's instructions, prepare a liquid acrylic mixture and apply it to the damage. After drying, the surface is treated with polishing paste.

VIDEO DESCRIPTION

Useful tips

Almost all cracks and holes in the shower tray can be repaired yourself, but you should first determine the feasibility of the repair. If the damage is serious, it makes sense to completely replace the pan.

The composition for cleaning and degreasing the acrylic surface should be selected carefully, since some solvents can damage the outer layer of the tray. It is recommended to carry out gluing in a well-ventilated area

The restored pallet can only be used after the adhesive has completely dried.

It is recommended to carry out gluing in a well-ventilated area. The restored pallet can only be used after the adhesive has completely dried.