Automatic washing machines perform a huge number of washes over their entire service life, washing tons of laundry of their owners. Designers develop them as reliably as possible for long-term trouble-free operation, withstanding heavy loads. But for the washing machines themselves to work well, they require us to use them correctly, starting with installation at the site of operation and connecting them to all communications.

The product must be installed in a well-ventilated area on a solid, stable base. The connection to the water supply must provide good water pressure, and the electrical supply must be adequate and stable. But the most important requirement is to connect the water drain to the sewer system.

Incorrect connection of the washing machine to the sewer can provoke spontaneous draining of the washing solution from the product tank.

In this case, the technology of washing clothes is disrupted and a malfunction occurs in the device program. If the drain is connected incorrectly, waste water from the sewer may enter the washing machine, which causes an unpleasant odor from the appliance and requires a thorough cleaning of all internal parts.

To comply with all the requirements when connecting the washing machine, you need to carefully study the recommendations of the device manufacturer.

To do this according to the operating instructions, you need to make big changes to the drain line of your home.

To simplify this procedure, many devices have been invented to help avoid the self-outflow of water from the machine tank or the unwanted ingress of liquids from the sewer into it. One of the options that simplifies the connection of the machine is a check valve for a washing machine on the drain, also called an anti-siphon valve.

Self-installation

The purpose of a check valve, unlike a fill valve, is to block the return of waste water to the washing machine drum. You can install it yourself.

One side of the valve is connected to a siphon or sewer pipe, and the other to a drain hose. The joints are firmly fixed and sealed.

Installation and alternative devices

In essence, an antisiphon is a tube of complex design, the ends of which differ in diameter. One end cuts into the drain or is connected to a siphon, and the other is connected to the drain system via a hose. All joints of the system must be sealed and periodically checked for leaks.

It is worth mentioning that purchasing and installing an anti-siphon is not always worth the money spent. According to professionals, purchasing this valve is relevant in two cases.

- Connecting the washing machine directly to the drain due to the impossibility of raising it a little. It is necessary to install a valve if the pipe is located too low.

- You had to connect the drain hose to the sink siphon. If the drain system hose has a standard configuration and is installed according to all the rules, then purchasing an anti-siphon does not make sense.

An anti-siphon will certainly make life easier if you often experience dirty water returning. You can install a valve designed to protect the washing machine drain yourself, but this does not mean that you need to do it just in case. Carefully study the entire drainage system before purchasing a check valve and decide whether you really need it.

When is it necessary to put

There are several reasons when an antisiphon is needed. See which case is yours. If you have doubts that the washing machine is installed correctly, we recommend reading this article, which shows a working connection diagram:

Step-by-step instructions for connecting any washing machine

With direct discharge to the sewer

The outlet hose is inserted directly into the sewer outlet. Of course, the connection method is very simple.

But there is a risk that used water will return from the sewer to the drum. Especially if the outlet level is significantly lower than the tank level.

Hence the disgusting smell of things after washing. Installing a check valve solves this problem once.

Wrong outlet level

The main rule for installing a drain hose is that its end should be 50 cm above the floor level. Sometimes, for aesthetic reasons, the hose is placed very low and you get that “siphon effect” with all that it entails: dirty water and the smell in the machine.

The sewer system is not done according to the rules

Perhaps the sewage system in the house is outdated or was originally assembled incorrectly. Inappropriate pipe diameter, incorrect slope, lack of water seal.

Unpleasant smell

A nasty smell in the place where the machine is located is an absolute indication for installing a check valve. It will block not only the flow of wastewater, but also the sewer smell.

Connecting the drain to the sewer pipes

This connection method is good, but also has its own nuances.

The main problem is that the height at which the end of the washing machine drain hose will be located cannot exceed 10 centimeters. This is unacceptable without installing additional equipment. The fact is that the end of the hose should be located at a height of 40 to 100 centimeters, depending on the recommendations given in the instructions. If it is impossible to ensure installation in the recommended range, and it is possible to connect only below 40 cm, then normal operation will be disrupted.

In this case, the water will drain on its own and the wash will take several hours, which is the smallest problem. Huge inconvenience will be created by the service life of the device, which will be reduced significantly. This is explained by the fact that the water level in the washing machine itself is higher than the location of the end of the drain hose.

You may be interested in an article on how to restore a cast iron bathtub yourself. You can read about how to choose a toilet seat here.

[rek_custom1]

Taking into account the laws of physics, it becomes clear that the water will drain by itself.

Principle of operation

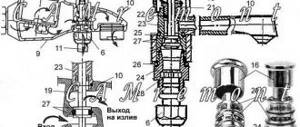

The antisiphon can be spring or ball. When the machine pumps out water, the pump (drain pump) creates pressure in the hose. Under pressure, a spring or ball is pressed against a special membrane, lifting the elastic band by 1-2 centimeters, and water flows freely. Then the pressure disappears, the shutter part returns to its place, tightly closing the passage. No waste water or odors can enter the machine.

There are several types of check valve:

- Whole. As the name suggests, it cannot be disassembled and cleaned. Such an antisiphon lasts 2-3 years. Then you have to change the whole thing. And if the water in your area is heavy or dirty, then earlier.

- Segmental. Consists of several collapsible parts. This valve can be disassembled and cleaned regularly. Sometimes a bellows connection is used to eliminate unnecessary vibrations.

- Wall-mounted. If aesthetics are important to you, then choose this option. This siphon is made of chromed metal or brass. It is installed on the pipe as close to the wall as possible or walled into it. It will be very appropriate if there is little space between the back panel of the washing machine and the wall.

- Mortise. Mounted directly into the pipe.

- Washing. Attaches to the siphon under the sink.

Types of valves

There are quite a few types of antisiphon. Before purchasing, explore the available options and choose yours. There are five options for such valves on the market:

- solid;

- segmented;

- wall;

- requiring cutting;

- installed under the sink.

There are no significant differences between them; all devices are designed for the same purpose - to protect the machine from the return of dirty water and to ensure the normal drainage of waste liquid. However, connecting specific washing machines to the drain has its own characteristics.

If the water in your water supply is far from perfect, it is best to purchase a segmented anti-siphon. This will ensure the possibility of subsequent disassembly and cleaning of the system from water debris and various deposits.

Important! Even if the quality of the water from the pipeline is good, it is necessary to change the valve every few years. The procedure is simple, you can do it yourself.

Anti-siphon wall

Wall antisiphons are expensive. Their use is justified when the drain is located in a small space between the walls and the outer panel of the washing machine. This type of valve is very compact and will significantly save space when located along the wall. Among other things, this type of anti-siphon looks quite stylish and can become part of the interior.

Flush-type valves are ideal for drains that pass directly through a sewer pipe. In this case, the drain is equipped with a tie-in, and a check valve is installed on it. The anti-siphon, which is installed under the sink, is usually combined with the sink siphon. It is suitable for almost every siphon model, does not take up much space, is practical and easy to use.

Tips and tricks

We have collected tips from master plumbers. We hope you find them useful.

Install in an easily accessible place

The outlet valve of the washing machine, installed on the drain, becomes clogged and breaks over time. And installing it in a place where it is difficult to reach will only complicate your life. In an emergency, you will need to quickly disassemble the valve, clean it or make repairs so that the laundry does not have time to be in dirty water.

Which to choose

List of the most reliable and popular check valves

- Italian exhaust valve Type: mortise. Body material: polypropylene. Installed in a drain pipe or attached to a hose to drain water. The mechanism is based on a spring with a rubber membrane.

- Czech valve from . Wall. The plastic case contains a water seal made of a ball with a spring. Universal: suitable for any hose. The main advantage is the affordable price.

- In third place is another representative of Italy from. The body is made of polypropylene. Installed in a siphon under the sink. The mechanism is spring.

- Mini-siphon from the Russian manufacturer ANI Plast. Mounts anywhere on the pipe. The locking mechanism consists of a spring-loaded polymer ball. The polypropylene body is resistant to aggressive environments and temperature changes.

- Siphon for connecting a washing machine from the Scottish company McALPINE. The beautiful plastic chrome-plated body does not spoil the aesthetics of the interior. Standard water seal with polymer ball and reflector.

Is it really necessary or how can I do it myself?

You can do without additional expenses by making the shutter yourself, using a standard corrugated hose that goes from the machine to the sewer. This is done simply - the hose needs to be organized so that the top point is above the level of the washing machine tank. The laws of physics and gravity will not allow the liquid to flow back into the “washer”.

But this is not a solution to the problem, but only a temporary solution. The fact is that the pump wears out due to the long hose and its bend. The pump has to work hard to move water through such a distance. In addition, cleaning turns into torture, since you have to completely disconnect it from the washing machine.

When connecting a hose to drain water directly to the sewer, use a rubber coupling. It will make the connection more airtight.

With this method, the waste pipe outlet must be raised 50 cm from the floor. Otherwise, the water seal will not work.

The hose may also not be long enough. To extend it you will need a piece of a similar hose and a special coupling. But over time, water begins to leak at the junction.

Operating principle of a check valve

The job of the washing machine drain valve is to allow waste water to flow in one direction into the drain. It also prevents the possibility of creating a siphon effect, which could cause spontaneous leakage of water from the machine. The design of check valves allows water to pass in one direction and block the flow in the opposite direction.

This can be done in the form of a damper or a ball with a spring. The check valve for a washing machine can be made of plastic or stainless steel, and the valves themselves have a rubber coating to tightly close the internal drain hole in the opposite direction.

There are check valves both in separate versions and built into siphons for sinks and showers. Siphons with check valves prevent water from entering sinks and showers into the washing machine, while simultaneously preventing the spontaneous outflow of waste solutions from the washing machine.

Often, if the washing machine drain is connected incorrectly, a siphon effect occurs in which the drained water from the bathtub or shower draws water out of the washing machine. To prevent this undesirable effect, anti-siphon devices are provided. The operating principle of these devices is such that when creating an anti-siphon effect, the vacuum created in the drain system is compensated with air to maintain the required atmospheric pressure.

This eliminates the self-flow of the aqueous solution from the washing machine. But such devices are not check valves and do not prevent water from entering the sewer into the machine, so they should be used if there is no possible ingress of water from the sewer system.

Their advantage over check valves is that they do not create additional resistance to the water being drained from the machine, and accordingly do not speed up the service life of the product’s drain pump. Check valves of almost all types create additional loads for drain pumps, because during the entire drainage of the waste solution from the washing machine, the pump is subject to the resistance of their springs.

Methods for connecting to the sewer system

Water drainage is organized in the following ways:

- The drain hose is attached to the edge of the plumbing fixture.

- Connects to the siphon under the washbasin.

- Screwed to the pipe under the bathtub.

In the first case, a permanent connection is not made, but during washing the possibility of using a bathtub, washbasin or toilet is limited.

Connecting to a siphon under the sink is the most popular method. The drain is mounted permanently, without restricting access to plumbing. A siphon with an outlet for an additional pipe is installed for connection. The hose is connected to the drain channel under the bathtub if the equipment is located correctly. The height of the connection point is taken into account for the normal operation of the check valve of the washing machine.

As an example of communicating vessels, consider the tank in a washing machine and the pipe connected to the drain. The knee at the bend divides it into 2 parts. If the long half of the tube is connected to the sewer, then the column of liquid in it will be greater than in the short part during drainage. The pressure in the communicating vessels is different, so the liquid from the container will drain until its amount is equal to the rupture point.

If the break point rises above the water level, there will be a pressure difference when the pump stops running, but instead of going down the drain, the water will flow back into the washing machine.

DIY washing machine drain valve installation: 5 steps

To perform installation, no special knowledge is required; basic skills in working with plumbing tools and sealant are sufficient.

The technician’s task is to ensure free access to the valve in case of cleaning or repair.

- Initially, the instructions are studied. It specifies the valve characteristics and provides installation recommendations.

- Before work, check the length of the hoses. It must be at least 1.5 meters.

- The valve is attached on one side to the drainage system pipe, and on the other to the water drain hose.

- In relation to the floor, the component is installed at a height of more than 0.4 m, and the hose - 0.7 m.

- All joints are sealed. Inspection of seams is carried out at least once a year.

Upon completion of installation, testing is carried out to check the joints for sealing quality. To do this, the machine is turned on in rinsing mode. Any leaks must be repaired.

Connection Tips

Professional plumbing services are not required to connect the washing machine, but errors when installing the drain lead to breakdowns in the future.

When choosing an installation method, you need to ensure that the hose does not fall into the water. Specialists know what to do in such a situation. The serviceability of the sewer system is checked before installation, the pipes are cleaned, and fast and free outflow is organized.

The tube pulsates while the machine is operating, so it is necessary to secure it firmly to prevent leaks. When the pump is turned on suddenly, a jerk occurs, which can cause the connection to break.

A special valve will help

You can protect yourself from the siphon effect of your washing machine using a check valve. This device controls water drainage and prevents waste from returning to the drum. Thanks to a special valve, the device allows water to drain during standard drainage, but closes the entrance to the machine if the intake from the sewer begins.

Manufacturers of household appliances are just beginning to equip new models of washing machines with built-in check valves. Owners of already produced machines have to take care of preventing the siphon effect on their own and purchase additional devices. You will have to choose from the following types of devices:

- solid;

- segmented;

- mortise;

- wall;

- installed under the sink.

Valves differ in the nuances of installation, size and scope of application. Thus, segmented ones are used in the presence of dirty tap water, as they are easily disassembled and can be cleaned from debris and scale without any problems. Wall-mounted devices are compact and attractive in appearance, they are more expensive and are installed if the existing drain is located close to the walls and the front panel of the washing machine.

Mortise valves are installed directly into the sewer pipe: first, the insert is mounted, and the device itself is fixed in it . Dampers installed to the siphon under the sink are considered universal, as they are suitable for all plumbing fixtures, are inexpensive and easy to connect.

You need to think about installing a check valve if the washing machine is connected directly to the sewer, the pipe is located low, and there is no way to raise the joint. When equipping the machine with a standard hose configuration and subsequent connection through a siphon, there is no need to worry: in this case, the siphon effect does not threaten.

Types of anti-siphon valves ↑

An anti-siphon valve is a small device made of plastic and equipped with a special tip for connecting to a household appliance hose. There are several types of antisiphons:

- collapsible;

- non-separable (have a solid plastic body);

- mortise (mounted into pipes exclusively by cutting);

- washing

The type of anti-siphon is selected based on the drainage device. If the water is too hard, the valve must be changed periodically, although in any case it will last for more than one year.

Wall Check Valve for Washing Machine