Many modern inhabitants are so accustomed to comfortable living conditions that they sometimes have no idea about the structure of a particular household or plumbing appliance. And they think about such questions only when the need arises to face this with their own eyes, for example, during repairs or during a forced replacement. Such “mysterious” devices include the siphon. Almost everyone knows and understands what a siphon is in plumbing, but not everyone understands why it is needed and how it works.

Technical features of the system

Bathroom waste and overflow

The design of the drain and overflow consists of pipes tightly connected to each other and ensuring the necessary tightness. When water reaches the corresponding opening in an uncontrolled flow, the excess flows into plastic or flexible hoses and goes through the sewer pipe. A corrugated tube is a practical option, since in a small room area it bends and extends in any direction. The device is equipped with a siphon to protect the bathroom from unpleasant odors emanating from drainpipes.

External parts of the system are made of stainless or galvanized steel, which corresponds to its high quality and durability.

When purchasing a system, you should pay attention to the high-quality execution of all elements and mechanisms, as well as the presence of special seals and cuffs. If they are absent during operation, serious leaks often occur due to insufficient tightness of pipe connections. They can be purchased separately according to the diameter of the coupling or pipe.

Today there is a wide range of bath drains, the prices of which depend on the technical features, material and configuration. Manufacturers produce standard plastic versions, as well as models made of expensive metals with applied ornaments or engravings. There are the following types of drain-overflow systems:

- regular siphon with plug;

- semi-automatic system;

- automatic drain mechanism.

A certain type has advantages and disadvantages, but their use depends on the design features and individual needs.

Selected varieties

In addition to the design features of the structure, siphons differ in type and method of application:

- If there is no space under the sink for a conventional drainage device or it needs to be installed under the bathtub, then you can use a flat siphon. It is easy to install, takes up little space, holds odors perfectly, but it has one drawback: if it becomes clogged, you will have to disassemble the entire structure.

- Due to the increase in the number of household appliances, sink siphons with two or even three separate side fittings began to be produced. Thanks to them, you can connect a washing machine and a dishwasher to one drain at the same time.

- Complex devices are made for kitchen sinks that combine two or more pipes for connection to sinks with several sections.

USEFUL INFORMATION: How to lay tiles yourself

Automatic system: pros and cons

A characteristic feature of an automatic flush is a complex device with a “click-clack” valve button equipped with a latch and a spring. These keys come in a variety of designs and styles. The material used is copper or brass, coated with nickel or chromium. Among the advantages of the system are:

- convenience of draining water;

- compact design;

- practicality and effectiveness in various cases;

- presentable appearance.

Automatic drain-overflow also has disadvantages, such as: difficulties in repairing the button, installation complexity with the need to involve a specialist, low service life of the spring to hold the valve, high cost.

This system is often equipped with an additional function for filling the bowl with water. It is suitable when it is not possible to install a mixer. The diagram of such a drain in the bathroom consists of a pipe line connected to an overflow hole and a drain. When turned on, water is supplied to the bowl through a connector on the wall, and automatically stops when there is an excess of it.

Main nuances

It is necessary to correctly assemble the plumbing equipment, based on the instructions included in the package with a diagram (of course, if the unit was purchased at a shopping center that monitors the quality of its products). Elite models with automatic control, as a rule, do not require assembly. The assembled units can only be slightly adjusted using corrugated parts, following the instructions in the same instructions.

The need for a responsible attitude towards the siphon assembly stage is easily explained by the fact that incorrect actions, even with the usual tightening of nuts, can damage fragile structures. For example, the same plastic. Some parts are installed only when the siphon is directly connected to the bath itself.

So, after final assembly of the product, it is necessary to check it for compliance with the declared quality. In other words, make sure that there is no mechanical damage - be it a stripped thread or a broken gasket. By the way, about the latter. There is a certain order for their installation. It must be followed.

Attention! Professionals recommend not to tighten all connections too much, since when connecting a siphon to a drain, you usually have to adjust all the elements again.

After checking that all parts are in good working order, you can install the bath siphon with overflow yourself.

Schematic appearance of a bathroom siphon

Features of a semi-automatic siphon

Semi-automatic design

The most practical systems are considered to be semi-automatic. Their design is distinguished by the presence of a control unit on the outside of the overflow grille. The device is designed to adjust the tension of a special cable. One edge is connected to the block, and the other to the drain plug using a rod on the collar, while the plug is firmly connected to the system as a single mechanism.

The control unit is always located on the back side of the hole and is presented in different design forms:

- handle with pad;

- button;

- swivel ring.

To open the drain at the bottom of the bowl, you do not need to immerse your hand in the water; you just need to turn the ring or handle on the end side of the bathtub. She will tighten (to close the drain) or loosen (to drain water) the corresponding cable, lifting the plug.

The disadvantage of a semi-automatic system is the likelihood of the cable chafing and the bolt mechanism jamming, but this is directly related to the quality of the design. To protect yourself from such problems, it is recommended to choose equipment from trusted manufacturers that guarantee reliability and durability.

Types of bath siphons

A siphon is a plumbing device designed to drain water into the sewer system and block the unpleasant odor entering the building from the sewer.

There are 3 types of drains, differing in their operating mechanism:

- manual (mechanical);

- semi-automatic;

- auto.

To use a manual (mechanical) device, additional methods of influence are not required. The drain hole is opened and closed manually using a stopper. This type of drain is quite simple, reliable, has a long service life, and is therefore the most popular.

The semi-automatic siphon is activated by a cable or lever mechanism. The drain is closed with a special shut-off valve. Most often, this design is used on the drain and overflow holes of water above the level. Since the assembly of this installation contains moving components and assemblies, its reliability is somewhat reduced.

The automatic drain is a single mechanism with the filling system. It runs on a built-in processor.

This type of siphon is equipped with a controlled click-clack valve. It is driven by the pressure of the water column. The automatic design allows you to fill the bath with water to the required level. In addition, it is possible to set the desired water temperature and maintain it. If the temperature drops, the shutter valve is automatically activated and the water is drained, and the filling device replenishes the amount of liquid.

To make siphons, materials such as plastic, stainless steel, brass, cast iron, and copper are used. The most commonly used are plastic drains. They are durable, easy to install and operate.

Standard drain system: simplicity and savings

The simplest drainage device in a bathroom is a system of pipes without mechanical or automatic levers or devices. A rubber or silicone plug is connected to the overflow grille on the wall of the bathtub via a metal chain and works by direct contact. The product range differs in the design of the pipe connection unit, the nature of the connection to the sewer pipe and the sealing of the joint areas. The system includes the following elements:

- A siphon is a removable zigzag pipe that is responsible for a water seal and preventing sewer odor from penetrating into the room. It is also a piping component for all pipes of the device. They vary in configuration, but the most common is the one with a deep shutter, where the amount of water held is more than 300 ml.

- Drain neck - connects to the hole located in the bottom of the bathroom. The design consists of an expanding tube with a built-in tightening nut and a chrome funnel that prevents debris from entering the siphon. The elements are connected using a reinforced stainless steel screw. The ring seal in the threaded part of the joint is made of high-quality rubber and is responsible for tightness.

- Overflow neck - installed on the wall of the bathroom and is structurally similar to the drain. However, the connection to the central network occurs exclusively through lateral drainage.

- Connecting tube - a soft corrugated tube connecting the siphon and the overflow hole, is necessary to drain excess water in the bowl. The connection to the elements is ensured by an overflow pipe.

- Auxiliary pipe – made in hard or soft design. Necessary for draining water from the siphon into the drain pipe.

The drain in the bathroom requires the presence of connecting devices to ensure the tightness of the joints. These include flat and cone-type gaskets complete with cap clamps. The latter is the most effective, as it provides reliable protection against leakage. The narrow part is inserted in the direction of flowing water into the opposite element and tightened with a nut.

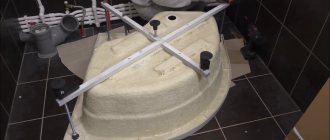

How to assemble a manual siphon

Before purchasing a siphon, measurements are taken of the drainage and overflow clearances, and the gap from the bathtub to the floor. Assembling and installing a manual drain device requires careful study of the instructions and diagram supplied by the seller. It is the same for all types of drainage.

The structure goes on sale dismantled. The set includes: seals, tubes of various widths, and a sump.

First you need to take the sump and put the largest flat gasket on its lower part. When installing seals, distortions (distortions) must not be allowed. Then (using a corrugated hose) you need to connect the sump to the outlet. When assembling plastic structures, an additional seal in the form of FUM tape is not required, whereas for metal drains it is necessary.

Next, you should find two holes of different diameters on the side of the sump. These outlets are provided for side drainage and connection to the manifold. In proportion to their sizes, you need to select a wide conical gasket and union nuts.

After this, take a fitting that will connect to the central drain. A union nut is installed on it. A seal is selected (its sharp end is installed to the pipe, and the blunt end is subsequently connected to the sump). The gaskets must be placed as tightly as possible without allowing them to rupture.

Upon completion of the described actions, a pipe is inserted into the siphon, which is later (using corrugation) attached to the sewer network.

After assembling the drain, you can begin its installation. There should be no extra parts left in the set. All components must be used for their intended purpose. To increase the tightness of connections, several gaskets cannot be used. Only 1 sealant is used for each joint.

To prevent leakage, it is advisable to regularly check the connections and replace them if necessary.

Material selection criteria

Plastic product

When choosing which drain/overflow is best for your bathroom, you should pay attention to the material of manufacture. In Soviet times, drainage systems for plumbing equipment were made exclusively from ferrous metals, as they provided resistance to corrosion, hot water, acid and alkaline compounds. Despite the rapid loss of its presentable appearance, the material showed high resistance to changes in temperature and pressure.

Today, manufacturers prefer to use plastic and non-ferrous metals. The first ones are affordable and are used in bathrooms with installation. The elements are universal in size, so the structure can be mounted for different sewer outlets and installed in non-standard variations.

Metal systems are superior to plastic ones in durability and workmanship. Bronze, brass or copper appliances have an interesting design and construction. The gratings are painted with nickel or chrome plating using the galvanoplasty method. Such drains and overflows, subject to the rules of operation and periodic maintenance, guarantee a service life of more than 10 years.

You can determine what metal the system is made of yourself:

- bronze is a hard, dark brown metal composed of tin and copper;

- brass is a durable alloy of copper and yellow zinc;

- copper is moderately ductile and soft, with a reddish tint.

Installation of drain-overflow systems

Semi-automatic and automatic devices differ from conventional ones by the presence of special mechanisms that open and close the drain hole using a valve rather than a removable plug. When installing one or another system, the height of the bathroom drain is at least 15 cm. The semi-automatic device is equipped with a stylish control unit made of metal. When turned, the chrome ring tightly closes the drain using a closing element.

The automatic system features an improved mechanism consisting of a spring-loaded moving part and a button. The first element has the function of fixing in a closed or open state, thereby blocking the drain hole after pressing the button. The advantage of a semi-automatic device is that it opens the drain without having to put your hand in the water. The automatic device allows you to control the position of the valve not only with your hand, but also with your foot, which makes it practical to use.

Installation features of other models

In addition to plastic devices, non-separable metal models are used, as well as automatic and semi-automatic siphons.

The main point that you should pay attention to when installing a non-separable model made of brass or copper is the angle of entry of the siphon pipe into the sewer. It should be minimal, otherwise leaks are inevitable, and no sealant will save you. In difficult cases, you will have to purchase some additional parts for the sewerage system in order to obtain the desired angle. Installation of the siphon is carried out using sealant and gradually tightening the threaded connections.

The installation of semi-automatic products will differ only in the installation of special controls. It is carried out according to the instructions, which are necessarily attached to such siphons.

But the installation of automatic drainage devices, especially if they have an electronic control unit, should be carried out by representatives of the seller or manufacturer: self-installation automatically voids the warranty on these products.