All plumbing products: taps, mixers and others, have a locking mechanism called a faucet axle. It is used to open or close the water supply, adjust the flow pressure, and mix hot and cold water. The axleboxes are connected to handles, wings and other parts of plumbing products, with the help of which manual pressure is applied to the faucet axlebox. This part is made of non-ferrous metals (usually brass) that do not corrode with moisture, hence the long service life of plumbing fixtures.

Main types and sizes

There are two main types of crane axle boxes on the market:

- Worm rubber.

- Ceramic.

You can find a large assortment of crane axle boxes of domestic or foreign production. In some cases, rubber mechanisms can be interchanged with ceramic types, but this requires understanding the appropriate dimensions. When replacing, take into account the difference in the number of splines. On the upper part of the rod for the flywheel, the number of such slots can be 20 or 24. Thread sizes are ½ and, accordingly, 3/8 inches. Both the diameter of the axle boxes and the landing location are different.

Expert advice

- If the valve seat is damaged in the worm axle boxes (cracks, depressions or chips), the center element is completely changed.

- A leak directly under the valve indicates the need to replace the seals.

- The creaking of the faucet or the need to apply force when moving the handle or valve warns of the need to lubricate the valve head. This will prevent further damage.

- The problem with the tightness of ceramic and ball axle boxes indicates the need for their complete replacement. Repairing the indoor unit is usually not possible.

- When rubber gaskets wear out, it is enough to cut out the required element from dense rubber or buy it in a specialized store and replace them.

Purpose and scope

The main task of the faucet axlebox is to ensure the supply of water when the mixer handle is turned. If such a part breaks, the faucet leaks: at first it just drips, and then flows continuously at the junction of the faucet base and handles. Another purpose of using such a mechanism is to control water pressure by narrowing or expanding the lumen.

Frequent errors and problems during installation

- When screwing in, the axle box must not be overtightened, as this will lead to the formation of leaks. It just screws in all the way.

- During dismantling, you may encounter the problem of the axle box sticking to the body due to its oxidation or rust. The following techniques are used to solve the problem:

- Treating the body with vinegar, special chemicals or oxygen-containing agents.

- Heating the body with a hair dryer.

- Slight loosening of the axle box. Overdoing it can lead to damage to the faucet and faucet.

- Drilling out the valve head is a last resort method, because... Subsequently, cutting of a new threaded connection will be required.

Differences between a faucet with a shower switch and a valve

The difference between the faucet and axle boxes can be in the throughput, the temperature of the flow water and the pressure for which a particular device is designed. The differences between faucet axle boxes with a shower switch and valves are in location, purpose and size.

A valve is a fitting used in the operation of process pipelines with a diameter from 15 to 2000 mm. Such pipelines are found in gas supply systems, water supply, housing and communal services, oil production, and energy areas. The function of the device is to lock the environment of pipeline fittings elements in two positions: “open”, “closed”.

In everyday life, a faucet with a switch is called a shut-off and control valve. Installed at the outlet of a pipe used in working with liquid or gaseous media or bulk materials. More often, such an element is installed to shut off gas at a water heater or stove.

Useful recommendations for choosing a faucet axle box for a mixer

Any device needs to be replaced after some time. Before buying a faucet for a mixer, it is important to consider some aspects. It is necessary to determine the size of the seat, the type and pitch of the threaded connection, the length and configuration of the rod, the number of splines, which is typical for imported products. In domestic versions, valves are “square”.

Before purchasing a new crane axle box, you need to find out the dimensions of the seat

Important! Imported and domestic models cannot be interchanged, therefore, to replace a Russian head with a foreign analogue, it is necessary to purchase a crane axle box with a flywheel included.

To replace a worn valve head, you should buy the exact same model from the same manufacturer. In case of choosing a modified analogue, it is necessary to take into account full compliance with the overall dimensions and interaction with the mixer. To eliminate mistakes, you should choose a crane axle box in a specialized store, having the old part with you.

We should not forget about the quality of water, which will affect the uninterrupted operation and duration of operation of the shut-off element. The cheapest options are offered by Chinese manufacturers. The cost of the valve head is in the range of 70-800 rubles. The domestic manufacturer produces high-quality products in the price range from 100 to 1500 rubles. The cost of a European brand crane axle box will be 450-2100 rubles.

When purchasing a new faucet for a bathroom or kitchen, you need to independently verify which faucet axle is installed in it. To do this, rotate the flywheel. For a rubber faucet for a shower or washbasin, you will need 3-4 turns, but for a ceramic one, only half a turn is enough.

As a rule, imported and domestic crane axle boxes are not interchangeable

Technical characteristics - device

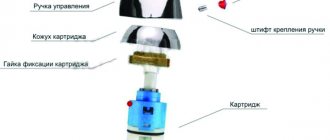

Design features of ceramic type crane axle boxes:

- Rubber ring adjacent to the pipeline.

- Bottom ceramic plate (flat type), non-movable.

- An upper ceramic plate that, when rotated, closes or opens the passage of water.

- Silencer for silent water supply.

- Two rubber rings located on the rod.

- The stem itself has 4 or 5 edges or a square type, which is found in old domestic products of the Soviet format.

- The axlebox body is collapsible or solid, depending on the design of the crane.

- The bracket is thin metal.

If we consider the design features of a worm-type rubber valve, the device is identical. The difference is that instead of ceramic plates, it has rubber gaskets.

Life time

The average period of operation of axle box cranes depends on the modification of the device:

- Worm drives last an average of 1.5 – 5 years;

- ball - from 3 to 5 years;

- ceramic – from 5 years or more.

However, the composition of water has a significant impact on the lifespan of products. The presence of certain impurities can significantly shorten the service life, whereas in clean water the device can work properly for decades. In this regard, experts recommend installing fine filters.

The intensity of use of the mixer is also important. Thus, screw heads installed in the bathroom wear out less than those installed in the kitchen.

The first sign of wear is not a leaking faucet at all, but the appearance of a characteristic rattling hum as a consequence of the occurrence of resonance in the valve.

How are they different from each other and how are they structured?

Worm- or ceramic-type devices vary in diameter, depth and seating location.

One side of the faucet fits into the hole for water supply, the other sits on the inside of the handle.

Depending on the design of the handle, the number of edges on the axle box also differs.

There are universal “tricky” handles that are adapted for installing a 4-sided axlebox, and if it is necessary to change the spare part - the axlebox using the “asterisk” type of installation. The main difference between the two different valve axle boxes is the closing of the valve seat with a rubber or ceramic gasket. Also, the shelf life of rubber gaskets is shorter than ceramic ones.

Design of worm valve heads for mixers: what are they?

Devices of different types are equipped with a rod. If you turn the handle of the tap, it comes out. After such a movement, the gasket in the device (usually rubber) completely opens or partially closes the valve seat: the lumen of the pipe for supplying water flow narrows or expands.

This gasket is made from different types of rubber. The service life of the axlebox depends on the quality of the material used. Wear is accompanied by the appearance of a hum in the pipes (air walking) when the tap is turned on.

Advantages:

- Low price.

- Prevalence of sale in the domestic market.

- Easy replacement.

- You can make the rubber gasket yourself.

Flaws:

- Short shelf life. Due to the fact that the rotation is carried out several times, the rubber wears out and breaks.

- You need to turn it a couple of times to shut off the water.

If water is leaking at the base of the handle with a worm-type valve axle, there is no need to change it. For the faucet to work properly, it is enough to remove the rubber gasket and turn it over to the unworn side.

Installation of ceramic valve heads for bathroom faucets, shower stalls (faucets)

Ceramic parts also have a simple design. The body is made either from chrome-plated steel or metal and brass. The faucet consists of 2 ceramic inserts. One gasket is stationary, the other rotates in the rod, blocking the water gap. But the shape of the holes is always the same, they fit tightly to each other. To open the tap, you need to turn the handwheel once.

Ceramics are sensitive to water containing impurities. If hard water with alkalis or rust constantly flows, the gaskets will turn yellow and dry out. Due to diligence close to each other, unpleasant sounds begin to flow. Of course, you can sharpen the ceramic spacers to remove plaque, but it is much easier to buy a new faucet axle box.

Main advantages:

- Operational life: from 3 years.

- Quiet operation.

- No effort is required when opening, just one half turn is enough.

- Wide range for all possible stock variations.

- Quiet operation of the crane.

Flaws:

- The price is higher than the worm type rubber valve.

- It is advisable to mount it on a faucet with an installed water purification filter.

Advantages and disadvantages

We propose to analyze the advantages and disadvantages of each valve head model in a comparative table:

| Worm crane box | Ceramic crane box | Ball valve | |

| Opening | Long. Several full turns of the tap. | Fast, silent. Rotation angle from 90 to 180⁰ | Fast, silent. Rotation angle from 90 to 180⁰ |

| Wear | Rapid wear of the rubber cuff | Slow | Slow |

| Sensitivity to water quality | Impurities of salts and metals provoke premature wear of the rubber seal. | Sand impurities can cause the mechanism to jam. Ceramics are neutral to chemical compounds. | Sand impurities wear out the surface of the ball element. |

| The need to install an additional filtration system | Not necessary | Yes | Yes |

| Repair features | The downside is that the water needs to be completely shut off. Plus, you can make the rubber gasket yourself. | Not suitable for repairing internal parts. | Non-repairability of internal parts. |

| Price | Low | High | Average |

Which is better for replacement - ball or wing?

Simplicity of design is the main feature of a ball-type axlebox. The role of the locking mechanism is performed by a metal ball with a hole passing through. This part works simply: to turn off the water, you need to turn the handle a quarter turn.

The disadvantage of the thumbwheel design is that you have to turn the faucet handle several times to turn off the water. Often such mechanisms are used in old domestic taps with two handles separately for cold and hot water. Ball and wing mechanisms are identical to each other, and therefore when choosing, they are guided by the type of axle box - ceramic or worm.

Features and principle of operation

First of all, it should be said that such parts have certain sizes and standards. At the same time, the standard design of a ceramic faucet allows it to be mounted even on faucets in which switching water from hot to cold and vice versa was previously performed using similar elements, but with rubber bands. However, this approach requires careful selection of a specific model.

The ceramic axle box stop valve has the following features:

- quite long service life. Therefore, it is rarely necessary to repair a ceramic faucet axle box, and it is easier to replace it together with the mixer, which has become unusable;

- To obtain maximum pressure, it is enough to turn the valve half a turn. However, not all users like the half-turn shut-off valve of the axle box. At the same time, experience comes with a little practice . The same applies to the repair of this part, for example, when the shut-off valve of the axle box for the mixer does not unscrew;

- Such products do not withstand the effects of water transported through utilities with an abundance of sand. He creates ceramic production. At the same time, ceramic faucet housing does not suffer particularly in water supply systems equipped with special filters to retain small particles;

- When compared with the price of products with rubber gaskets, it should be said that a ceramic axle box stop valve is more expensive. However, in relation to the cost of the mixer, this is a completely acceptable expense;

- An important factor is the ease of repair and replacement of such systems. The performer is not required to have any special education.

Ceramic crane axlebox is a modern type of similar parts that does not require the installation of rubber gaskets

Advice! When replacing a crane axle box of this type, it is better to come to the market with the part dismantled so that the seller can choose the most suitable model. Due to the fact that such designs are refined and modernized over time, the search for exactly the same product may be unsuccessful.

The main element of the 1/2 inch ceramic axle-box tap is the frame. Two plates with holes are attached to it. They are installed in special grooves. It is quite natural that ceramic materials are used as raw materials for the manufacture of plates. When the valve turns, the moving part of the valve axlebox shifts, as a result of which the holes either align, opening, or, conversely, shift, closing.

Please note that a ¾-inch ceramic axle stop valve usually has larger gaps, but there are models on the market with a strictly defined diameter, thanks to which a specific flow can be created.

Selecting a suitable valve head

If you need to change the valve head, the question arises about the practicality of one or another option. Plumbers recommend paying attention to the following features:

- type of design - old Soviet-style models, as a rule, have rubber wing-mounted devices with a tetrahedral valve. It is quite difficult to find one like this today, and therefore you will have to change the entire tap;

- the diameter of the valve must match the opening of the tap;

- The seating depth must correspond to the size of the part.

Types and brands

Manufacturers of plumbing fixtures, as a rule, produce not only faucets, but also spare parts for them.

Popular brands at inexpensive prices:

- Kaiser.

- Ledeme.

- IMPRESS.

- Iddis.

Average price category:

- Vidima.

- GranFest.

- NOBILI.

- Rossinka.

Premium Quality:

- Blanco.

- Hansgrohe.

- GROHE.

approximate price

Models of crane axleboxes differ little from each other in price; the difference often does not exceed about 50 rubles. Key price differences are based on country of manufacture:

- the cheapest valve heads are made in China. On average, their cost ranges from 70 to 1,000 rubles;

- Russian ones cost about 200 – 1,500 rubles.

- European brands - from 450 to 2,500 rubles.

This variation in cost is due to the design features and materials used in the manufacture of products. These differences determine the functionality and durability of the unit, so when choosing the appropriate model, price should not play the role of a determining factor.

Repair and replacement

If the faucet is leaking, it means you need to replace the faucet axle. This can be done in a couple of minutes, but without certain knowledge you will not be able to carry out the replacement yourself.

To unscrew the valve axle box, some experts recommend using adjustable wrenches. This is the first mistake. A nickel-plated surface or other coating is quite fragile. Therefore, when carrying out such manipulations, there is a risk of not only damaging the core, but also spoiling the appearance of the mixer. For these purposes, it is better to use a 17 socket.

Possible faults

The first signs of a faulty stopcock are unpleasant sounds and water flowing when the handle is turned completely. Possible causes of the malfunction:

- Leaking from under the flywheel. The gaskets on the rod are worn out, usually there are two of them.

- Ceramic O-rings chipped. It cannot be repaired; the entire part must be replaced.

- Worn ceramic plates are also beyond repair. You just need to change it.

- The rubber plate can be repaired by turning the worn side over, or replaced with a new gasket.

- Hard water scale on ceramics cannot be repaired. Signs: when disassembling the spare part, the ceramics are not white, but brown, and the plates do not fit tightly to each other.

Replacing the old one with a new one with your own hands

They turn off the cold and hot water on the pipe and begin to replace the new device instead of the old one.

Tool:

- Socket head No. 17.

- Pliers.

- Screwdriver.

Replacing crane axle boxes:

- The cap is removed from the flywheel.

- The fastening bolt under the valve cap is unscrewed.

- The tap valve is removed.

- The tap thread is cleaned.

- The fittings are removed from the mixer.

- FUM tape is screwed onto the valve thread.

- A new axle box is screwed into place of the old worn part.

- The water flow is checked and the valve is tightened until it stops.

If the valve cannot be removed due to rusted threads, the tap is heated with a warm stream of air from a hairdryer. Then grab it with a towel and slightly loosen the part with pliers. After this, the thread is unscrewed freely.

Repairing the locking mechanism is possible either with your own hands or with the help of an invited plumber. You can determine for yourself what kind of axle box crane is needed by conducting a test. If you turn the handle up to half a quarter, it means you need ceramic, if several times before opening, you need rubber. Moreover, the latter option can be repaired, but ceramics cannot be repaired when worn out.

The faucet axle box is a necessary element of any faucet; if it breaks, the faucet begins to leak. Replacing it yourself is not difficult, but you should pay attention to the rules for choosing a crane axle box and the stages of its installation.

How to change the faucet axle in a mixer: sequence of actions

Before changing the crane axle box, you should prepare the necessary tools and materials. To do this, you will need an adjustable and pipe wrench, Phillips and flathead screwdrivers, pliers, a knife, thick rubber and rags. This procedure does not cause any difficulties, so it can be performed independently without the involvement of specialists.

Related article:

Faucet with hygienic shower: the best way to make your bathroom comfortable

Types and advantages of installation. What does the device consist of, how to choose the right one. Rating of models and manufacturers.

Before replacing the faucet, it is necessary to turn off the water supply. Next, remove the decorative cap, which is located in the central part of the valve. Use a screwdriver to unscrew the mounting screw. Using light rocking movements, remove the valve. Armed with pliers, you need to unscrew the decorative nut.

Helpful advice! When unscrewing the nut, it is recommended to place an elastic band or a piece of fabric between the element and the pliers, which will eliminate the possibility of damage to the lining.

Next, the question arises of how to remove the crane axle box. Using a pipe wrench, the element is unscrewed from the seat by grasping its upper part with special notches. The procedure is carried out counterclockwise. Next, you need to clean the inside of the faucet.

After replacing the crane axle box, you need to install a decorative nut

Using a special oil composition, lubricate all threaded connections. Using a wrench, you need to screw a new crane axle onto the prepared seat, which is done clockwise. Before this, the part must be wrapped along the thread with several layers of tow or fum tape, which will ensure a tighter connection. However, there should not be too much sealing material, since if there is increased pressure on the thread, it may burst, which will damage the faucet or mixer.

Next, the decorative nut is screwed on. The valve is installed in its original place and securely fixed using a fastening screw, onto which a decorative cap is placed. After all work is completed, the water supply is turned on and the tap is checked for leaks.

Important! To change the direction of movement of the crane box when opening, unscrew the locking screw, which then needs to be secured on the reverse side.