Just 10-15 years ago, the choice of sanitary containers for the bathroom was limited to a dozen models of different sizes, oval or rectangular. Nowadays, the assortment of bathtubs in construction stores amazes the imagination of the most discerning and demanding customers.

The presented models differ in the material from which they are made, size, shape, wall thickness, the presence of additional options, and most importantly, price. Having paid a lot of money for a bathtub, buyers often wonder which bathtub is best to choose so that it lasts a long time. In this article we will tell you what sanitary washing containers there are, as well as how they differ.

Cast iron bath

Cast iron is a traditional material for making sanitary containers for washing. Bathtubs from this material have been made for the last 100-150 years. They have a high mass, which is explained by the properties of the material, low thermal conductivity, and high strength.

Cast iron bath

The white color of the bathtubs is given by the enamel coating, which is quite difficult to care for in order to keep it in its original form . In modern models, instead of enamel coating, a polymer coating is used, which is more unpretentious in maintenance. Cast iron models come in only oval and rectangular shapes. These products have the following advantages:

- Low noise. Compared to steel models, cast iron bathtubs are considered low noise. This means that the process of collecting water into such a container is quieter.

- Low thermal conductivity. The temperature of water collected in a cast iron container drops by only 5-10 degrees per hour, which allows you to comfortably perform hygiene procedures, since the water cools slowly at this time.

- High strength. Cast iron is considered a strong, wear-resistant material, so a container made of it can withstand high loads without deforming.

- Long service life. A high-quality cast iron container will last 50 years, during which time only cosmetic defects will appear on it.

Important! The disadvantage of cast iron models is their heavy weight, which complicates transportation and installation, as well as the difficulty of caring for the enamel coating. To avoid damaging the enamel, you must avoid using abrasive detergents and acidic bleaches that corrode the coating. When deciding which bath to choose, pay attention to the condition of the coating; it should not be chipped or damaged.

Reliable manufacturers

When choosing an acrylic bathtub, you need to pay attention to the manufacturer. Famous brands rarely offer marriage. But in any case, it would be useful to read customer reviews. Here are a few trusted brands offering quality products.

BAS (Russia)

It works on Italian equipment and uses imported components. Plumbing fixtures meet European quality standards. The line includes more than 100 models with a guaranteed service life of 10 years. Acrylic polymer is used in production. Sometimes there are defects and products with an unpleasant odor.

Ravak (Czech Republic)

Uses modern equipment and high-quality raw materials. Bathtubs are made from a thick layer of cast acrylic. Offers a large selection of custom shapes and sizes. The warranty is 10 years, for additional equipment - 2 years. When choosing an acrylic bathtub from this manufacturer, you need to be wary of fakes. Among the disadvantages, we can note the difficulty in finding accessories and components for some models.

Acrylic bath Ravak

Cersanit (Poland)

It has an excellent price-quality ratio. Produces a separate line for people with disabilities. The warranty period is 7 years. The bathtubs are covered with a not too thick, but dense layer of acrylic. Economy class products are not very durable. In addition, factories in Russia and Ukraine sometimes produce defective products.

Roca (Spain)

Offers more than 200 models in different sizes. Uses a layer of acrylic of at least 6 mm for coating. At the same time, the price depends on the components, and simpler products are not inferior in quality to expensive items. Provides a 8-10 year warranty on coating and 2 years on components. When choosing a bathtub, you need to be careful, since the Russian plant produces defective sanitary ware, and there are fakes on the market.

To know how to choose a good acrylic bathtub, you should study the issue comprehensively. Quality is determined by many details. When paying a considerable amount for a product, you need to be sure that it will serve well for many years.

Steel bath

Previously, steel models were considered only as a cheaper and short-lived analogue of cast iron washing containers. However, with their operational and technical characteristics they are much closer to acrylic bathtubs. Sanitary containers made of steel are quite light in weight, which is 3-5 times less than that of cast iron.

Steel bath

The service life of models made from this material does not exceed 20-25 years, but they cost 2-3 times less. Steel bathtubs are produced in oval, rectangular, angular, round shapes and coated with enamel or a polymer composition. They have the following disadvantages:

- High thermal conductivity. Sanitary containers made of steel cool faster than other types of bathtubs (cast iron, acrylic, ceramic). Because of this, it is uncomfortable to wash in them for a long time. This drawback can be eliminated when installing the container by treating the bottom with polyurethane foam or other insulating materials.

- High noise level. Steel has a high resonating ability, as a result of which the walls of the wash container amplify the sound of falling water. Therefore, when water is filled, the steel bathtub makes a lot of noise. This defect is partially eliminated by applying polyurethane foam to the bottom, which reduces the resonating ability of steel.

Acrylic bathtubs

Acrylic models have appeared on the market en masse only in the last 10-15 years, but at first they did not inspire confidence among buyers. Affordable price, excellent performance and long service life quickly made acrylic bathtubs the most popular among analogues in the same price category made from other materials. The main advantage of acrylic is that various models of bathtubs of the most intricate shapes are made from it.

Acrylic bath

Sanitary containers made of this material are round, oval, angular, or heart-shaped. They are produced in 2 types:

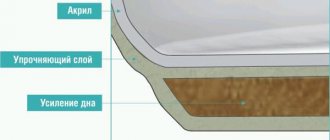

- The reinforcement frame of the bathroom is a fiberglass base on which an acrylic coating is applied. This type includes more expensive, durable and wear-resistant models.

- The sanitary container is made of 2 layers of extruded acrylic. Such models have lower strength, they are cheaper, but last less.

Important! The service life of acrylic models, guaranteed by the manufacturer, is only 7-15 years. They are easy to care for; however, you should follow the manufacturer's recommendations when choosing cleaning products. Small scratches on the surface of the bathtub can be restored using liquid acrylic, and the former gloss can be restored by polishing.

Professional craftsmen claim that installing acrylic models is more difficult than other types of bathtubs. Since they weigh only 10-15 kg and also do not have mechanical strength, improper installation leads to the bottom of the container splitting when the load increases. Also, during operation, you need to take into account that acrylic melts at 150 degrees, so too hot water leads to deformation of the bathtub.

Quaryl baths

Quaril is a modern, technologically advanced material produced by combining functional acrylic and durable quartz. Quaril is used to produce exclusive, expensive bathtubs with excellent performance characteristics. Models made from this unique material are heavier and stronger than acrylic ones; they have low thermal conductivity, like cast iron. Quaril baths come in various shapes, colors and sizes and are produced to individual orders.

Quaril bath

The addition of quartz improves the following qualities of acrylic:

- Thermal conductivity. Models made from quaril are not inferior in thermal conductivity to cast iron bathtubs, which perfectly retain heat during use.

- Low noise. Adding quartz reduces the noise level when collecting water into a container made of this material.

- High temperature resistance. Models made from this material can be used at any water temperature without restrictions.

- Strength. Models made from quaril are highly durable; they do not crack or deform under intense load.

- Easy to maintain. The structure of this material repels dirt, so caring for it comes down to periodic disinfection and rinsing.

- Ease of installation. Higher mechanical strength allows you to install quaril baths without frame equipment.

Important! When deciding which bathtub to choose in the premium class, pay attention to models made of quaril. They have excellent technical and operational qualities, as well as unsurpassed functionality. For ease of use, they are equipped with built-in armrests, handrails, and headrests. Expensive models include hydromassage functions, built-in radio and other useful options.

Bathtubs of various shapes and sizes

In the manufacturing process of modern bathtubs, various materials are used to give the product different shapes. To determine the type for specific products you will not need significant effort. Thanks to this factor, the bath not only becomes more aesthetically attractive, but also the space becomes more limited.

Traditional or rectangular

The production of traditional or rectangular bathtubs is based on various materials. In addition to standard products with dimensions of 180x80 cm, within the RNA there are models whose dimensions range from 120x70/75/80 cm, that is, “sedentary”, to those that have full dimensions.

Corner baths - help optimize space

Despite the bulky non-standard shape, corner baths are designed for more rational use of organizing bathroom space, including those of modest size.

At the time of purchase, you should pay attention to the type of bathtubs:

•

are they right or left

•

whether they are symmetrical or asymmetrical design

Production is mainly based on acrylic, steel or artificial stone to order. If the model consists of artificial stone, there is hydromassage and other options included. If the bathroom has a large area, there is convenient compatibility with shower cabins.

Corner baths have a wide range of sizes and depend on how symmetrical their shape is, and therefore the following options are possible:

•

120x120 cm to 180x180 cm - symmetrical models;

•

120x60 cm to 190x170 cm - asymmetrical models.

Oval bathtubs - laconicism in everything

The production of oval bathtubs is carried out from any material used for these purposes. This bathtub is very laconic and has a soft shape, creating a relaxing, cozy interior. The main purpose of such models is hydro or air massage. As a rule, they do not have headrests and armrests and special elements designed for sitting. There is variety in the size range, and the standard ranges from 140 to 210 cm.

Round bathtub - with a desire for ideal

Round bathtubs have a truly exclusive shape. Size is critical as they can be double or multi-local. Such bathtubs are most convenient for installing hydromassage nozzles and working with them. The main purpose is not limited to hygienic procedures, but is a relaxation device.

Regardless of the size range, ranging from 140 to 210 cm in diameter, the installation provides for the replacement of a sufficient area, which is accessible from all sides. As a rule, production is based on acrylic, somewhat less often than steel. For exclusive models, artificial or natural stone, etc. is provided.

If we talk about the advantages and disadvantages, you need to take into account the needs of family members, do not forget that installing a bathtub is a very important task for a long-term user. First of all, the interests of the elderly and children should be taken into account. For the elderly, a sit-down bathtub with a depth of 60 to 80 cm is best suited, and for the elderly, a spacious, shallow bathtub is most convenient.

To perform water or hygienic procedures with maximum comfort, sufficient length and depth should be provided. The minimum standard width level is from 70 to 80 cm, which is suitable for people of standard build. In order for the bath to be deeper without becoming bulky, manufacturers use flatter sides.