What are marble baths made of?

An exquisite natural marble bathtub is created from a single stone shard using special computer equipment equipped with a precise cutting and grinding mechanism, as well as computer control. Using this equipment, specialists can produce the most original bathtub models for any customer. A solid bathtub bowl is cut out of a block of marble, after which it is carefully processed, polished and coated with special materials. Marble is soft and malleable, making it quite easy to work with. The density of marble ranges from 2650-2900 kg/m3.

Natural marble is a noble material. Its beauty and elegance allows you to embody any interior and add royal luxury, color and aristocracy to it.

It has a wealth of shades, but more often it is cream, beige, and gray. The patterns and colored veins in the structure of marble are unique. In addition, these inclusions can be of different colors, which makes the marble even more sophisticated and interesting. After polishing, marble shines with its natural shine.

Advantages and disadvantages of finishing

Decorative stone is used not only in the production of cast bathtubs, but also in interior decoration. It can imitate any natural material; modern technologies make it possible to accurately convey texture and color. The surface is seamless.

But a stone bathroom can become dark, so it is better to add multi-level lighting in the room. Another disadvantage is the formation of scratches on the surface. They are clearly visible on walls and bathtubs in black, chocolate and dark gray. Therefore, when choosing a finish, it is better to choose beige, light gray or sand artificial stone in the bathroom.

Pros of marble baths

Marble baths have inexhaustible advantages, the most important of which are exclusive design and high aesthetics. A marble bathtub will bring its owners and guests a unique experience and aesthetic satisfaction. Bathtubs made of artificial marble have many advantages.

They do not fade for a long time and do not change their original color, do not change visually and remain in their original state for a long time. The main advantage of artificial marble is the unique ability to create the most simple, unusual shapes of bathtubs from it. The appearance of such a bathtub can be shaped as you like: you can increase the size, radius and depth, modify the corners and other elements and characteristics of the bathtub.

Among the positive aspects of marble baths are:

- Strength and durability. Natural marble is a fairly strong and durable material. Colored marble has especially such properties. However, in strength, natural marble is inferior to artificial marble, which has greater strength and abrasion resistance due to its polymer-mineral structure. Cast marble has impact resistance and structural integrity, unlike its natural counterpart, which can crack under heavy loads. Thanks to these positive qualities, cast marble bathtubs can be thin, but still withstand heavy loads.

- Environmental friendliness and radioactive safety. Natural marble is particularly environmentally friendly, since it does not emit various substances and toxins. Artificial marble contains synthetic impurities, which makes it less environmentally friendly. Marble belongs to class 1 radioactivity and is therefore quite suitable for use as a building material.

- Noise insulation. Due to the physical properties of the material, the noise of impact on the surface of the bathtub will be almost inaudible.

- Resistance to temperature fluctuations. Thanks to this quality, the marble bath does not overheat or overcool, which preserves the structure of the bath and does not affect its durability.

- Thermal conductivity. Artificial marble has extremely low thermal conductivity and thermal expansion, which makes it a fairly warm material. In addition, cast marble is a dielectric. Natural marble is a more thermally conductive material than artificial marble.

- Hygiene. The bathtub material is resistant to the proliferation and rapid spread of microorganisms and fungi, and therefore does not require particularly frequent cleaning. It can be periodically rinsed and cleaned with special compounds to avoid the development of infections.

- Moisture resistance. Artificial marble has excellent moisture-proof properties, due to which various cracks and deformations do not form on it. Natural marble also has low water absorption rates, however, it is higher than that of artificial marble, so natural marble is more at risk of cracking.

- Variety of shapes. This bath can be made in any shape. This is especially true for artificial marble, thanks to the unique technology of its use in the manufacture of bathtubs.

- Ease and simplicity of installation.

Marble combines well with many other building materials, such as wood, metal, and ceramics. Thanks to this, a marble bathtub will fit perfectly into any interior, for the design of which any finishing materials were used.

Modern manufacturers

Among the best manufacturers of cast marble bathtubs are the following:

Marmite

Marmite is a Polish company specializing in the production of cast marble products. Products are manufactured in Poznan, Poland. The company's product range includes over 2 thousand models, which are supplied mainly to European countries. The products comply with all European sanitary and environmental standards. Marmite marble baths come in different shapes and sizes, and come in a variety of colors. The shine of the products surpasses even the shine of natural marble. The complete absence of seams on Marmite products is its significant advantage.

Riho

Riho is a Czech manufacturer, one of the most popular cast marble products on the European market. Bathtubs from this manufacturer go well with any interior design solutions and will decorate any bathroom beyond recognition. The products meet all modern quality standards.

Marmorin

Marmorin is a Polish manufacturer that produces high-quality products. The complexity of shapes and innovative style distinguishes this company from others. The company specializes primarily in the production of granite kitchen sinks, shower trays, porcelain stoneware bathtubs and sinks, as well as cast marble for the bathroom. All the company's products have excellent performance characteristics, high quality and meet modern standards. Marmorin's collaboration with its partner BioCote, which has developed leading antimicrobial silver ion technology, ensures that products are protected against bacterial growth and the spread of fungi.

Kaldewei

Kaldewei is a German company that produces sanitaryware products made from cast marble. The company differs from others in its long warranty (about 30 years) and variety of forms. The shapes of Kaldewei bathtubs can be very diverse - rectangular, oval, octagonal, asymmetrical.

Tips for choosing shape and size

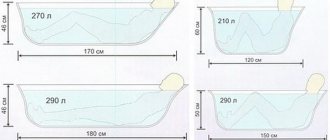

The bathtub is the center of attention of the entire room, its key component, which can either advantageously emphasize the features of a certain style or spoil the decor with an inappropriate shape or color. The variety of bowl shapes for bathtubs made from cast marble is much wider than those made from natural marble. Anyone can choose the option they need. The shape directly depends on the installation method:

- Standing separately;

- Wall-mounted.

In the first case, the bowl can be a real work of art, especially if it was made to order. This type of product is a bowl, which is located at a distance from the walls. In some cases, special legs are provided, which can have a wide variety of shapes and add special chic. Its edges can be either straight or rounded. The edges can be asymmetrical, reminiscent of sea waves. The silhouette itself can be oval, trapezoidal, almond-shaped, round, polyhedron-shaped or asymmetrical. Such models look very unusual. They are appropriate to be placed in spacious bathrooms . They usually take pride of place in the center of the room. A specially paved small pedestal and a floor-mounted high tap will effectively complement the non-standard font. The disadvantage of this installation location is:

- Difficult supply of communications to drain holes, which should remain invisible.

- You will have to take care not only of the internal, but also of the external surface.

- Use of a large amount of usable space.

The wall-mounted installation method, due to its compactness, implies placement in small bathrooms . According to the shape of the bowl, the following options are distinguished:

- Rectangular;

- Asymmetrical;

- Quadrant;

- Angular.

All of the above models can be equipped with a hydromassage system. The choice of one shape and size of bowl will depend on the area of the room and your personal preferences.

As for

the color scheme, two options are considered the most harmonious:

- When the bathroom has a distinctive color and serves as the highlight of the room. In this case, the non-standard color of the product must be supported by several smaller details. For example, a wine-colored bowl can be complemented by large candles of the same color and a large bath towel. Or a small rug and wall shelf in a similar shade. The surface does not have to be monochromatic. It can imitate the color of natural stone or other materials. In this case, the bowl should be a contrasting color in relation to the colors of the walls or floor. Then you will achieve the desired effect, and all attention will be focused only on the luxurious bath.

- The second option is the most traditional - when the color of the bowl matches the overall color scheme of the bathroom. This interior looks harmonious and complete. And the bathroom becomes an integral part of it. Usually the shade closest to the color of the walls is selected. But the flooring may be several shades darker.

A well-chosen shape and color of the bowl will help create a unique interior that does not require additional decor. After all, the impeccable appearance of marble baths is already the main decoration of the room.

Cast (artificial) marble

Currently, bathtubs made of cast marble are quite popular. Thanks to ultra-precise equipment and professional, high-quality processing, they look very much like marble.

Cast marble is an artificial material that perfectly imitates natural marble. This material looks luxurious and expensive and brings a feeling of wealth to the interior. The composition of this composite includes marble chips, quartz sand and solid polyester resin, which, when combined with mineral elements, acquires high mechanical strength. The more marble chips are in the composition, the more natural the material is considered.

An important advantage of cast marble over its natural counterpart is the ability to be painted in any desired shade, thanks to the addition of a special coloring pigment to the chemical composition of the material. A product made from this artificial material can be of any shade - red, emerald, pink, bright purple, with different textures, thanks to which such products can be used in the most daring and extraordinary design solutions. Cast marble is usually used to make baths of any shape and size, sinks, toilets and bidets, window sills, kitchen countertops, bar counters, and fireplaces.

The surface of cast marble is always coated with a special gel-like composition for coating composite products - gelcoat.

This protective material gives the product strength and glossy shine, and also protects it from ultraviolet radiation, moisture and mechanical damage. It is applied in a layer of up to 1 mm. Transparent gelcoat makes the surface look like natural marble or black granite. Colored gelcoat can give the surface shade, different patterns and designs.

The structure of cast marble, covered with a layer of gelcoat, has a smooth, non-porous coating that is quite easy to clean, since dirt practically does not linger on the surface. When cleaning the material, however, the use of abrasive substances is prohibited, as their particles can scratch the surface and thereby spoil its appearance. To clean cast marble, you need to purchase special detergents.

The advantage of bathtubs made of cast marble is the absence of seams, due to the presence of two-component glue. In addition, the material is hygienic; its moisture-resistant structure prevents the spread of fungi and mold.

The material is resistant to most common chemicals. Only lemon juice and acetone with prolonged exposure can damage its surface.

Typically, cast marble products are made to order, but there are companies that mass-produce standard bathtub models in traditional colors and basic configurations.

Disadvantages of using cast marble

There are also negative aspects associated with the use of bathtubs made of cast marble:

- Stone baths are more expensive than baths made from other materials.

- These bathtubs are 95% natural stone and weigh a lot. This complicates transportation and installation.

- Sometimes, during operation, chips and scratches appear on the surface of the bowl, resulting from increased impact loads or the use of aggressive chemicals and cleaning agents, including abrasives.

- It is necessary to rinse the surface of the bathtub after each wash or wash.

Disadvantages of marble baths

Marble is a carbonate sedimentary rock, so it is not resistant to acids and food coloring, so marble baths should not be exposed to these substances. Also, marble baths should not be subjected to thermal shocks, or hot tea or other liquids should be spilled on them, as this can damage it.

Do not expose marble baths to abrasive particles, such as sand, as they will scratch the stone. To clean the bathtub, you will need to purchase special formulations based on natural and synthetic wax.

Natural marble is a more fragile material than its artificial counterpart. Therefore, a bathtub made of natural marble requires careful handling. If there is a possibility of strong shock loads on the bathtub, it is better to purchase it from an artificial material.

If there is significant damage to a bathtub made of either natural or artificial marble, it will not be so easy to repair. If a bathtub made of these materials cracks and splits, after repairs are made it is unlikely to have its original satisfactory appearance and therefore may have to be replaced.

Marble, especially natural marble, has quite a lot of weight, so it will exert considerable pressure on the load-bearing reinforced concrete slabs. Bathtubs made of cast marble have less weight, and they are thinner, which reduces the load.

In addition, the high cost of products, even those made of artificial marble, as well as the equally expensive costs of repairing them, is a significant drawback of these baths.

Shapes of marble baths

The shapes of bathtubs made of both natural and artificial marble can be very different. They can be oval, rectangular, round, and even multi-faceted.

The wide variety of shapes of these baths is due to the material itself and the capabilities of innovative equipment. Bathtubs made of marble can be made either symmetrical or asymmetrical, to suit every taste of the customer.

Kitchen in black and white colors.

Read why laminate flooring creaks a year after installation here.

Liquid granite reviews: https://trendsdesign.ru/materialy/granit/zhidkij-granit-novaya-perspektiva-v-stroitelstve.html

Prices for marble baths

The high price of products made from natural marble is due to its high cost. Natural marble is a natural resource and its reserves cannot be restored. Also, the cost usually includes the cost of transporting the material from the deposits to the plant. Processing this material requires high-tech expensive equipment, which also affects the cost. Therefore, few people can afford a natural marble bath. The minimum cost of bathtubs made of natural stone is at least $5,000.

The price of bathtubs made of cast marble is much lower, and in general, similar to their acrylic counterparts. Cultured marble bathtubs cost $1,000 and up. The production of products from this material requires significantly less working time and resources.

Features of using the material in the bathroom

The casting method is suitable for creating bathtubs of complex shapes. Solid construction is a prerequisite for a long service life, which is why companies do not produce products with glass inserts.

Agglomerate is often combined with mother-of-pearl, onyx, and natural wood panels. This allows you to create a luxurious atmosphere in the room.