The weight of a cast iron bathtub is one of its main disadvantages. This drawback causes us the most inconvenience when dismantling and installing it. The heavier and larger the bathtub, the more difficult it is to take it out or bring it into the apartment, and the more you will have to pay for its transportation.

Knowing how much your old or new cast iron bathtub weighs, you will be able to argue reasonably with the movers and save your money. And it is possible that after learning about all the advantages of cast-iron bathtubs and methods for their restoration, you will completely refuse to replace it.

Classification

Let's consider the classification of Soviet cast iron products based on width and length.

The 140x70 cm model is most often installed in small spaces. The maximum weight of such a bathtub is 80 kilograms, and the capacity is 150 liters. However, this option is not suitable for an adult who wants to enjoy lying in warm water. After all, here you can only take a sitting position.

The following model is suitable for a standard room. The weight of a cast iron bathtub 150x70 is 95 kilograms.

It is quite rare to find products with dimensions of 160x70 cm. To take a bath, it is enough to take about 170 water. In this case, the mass is 100 kilograms.

More modern bathroom layouts require the installation of an elongated structure. That is why a product with dimensions of 170x70 cm is ideal for such a room. What is the weight of a 170 cm cast iron bathtub? This parameter is 119 kilograms, and the capacity is up to 180 liters.

Large-sized bathtubs are often produced to order. The size of such a structure is 200x70 cm. This model is only suitable for large areas.

If we compare Soviet baths with modern products, their weight has become significantly less. For example, the weight of a domestically produced 150 cm cast iron bathtub is 20 kilograms more than that of a modern model. However, weight reduction is most often associated with savings on materials. This leads to a decrease in heat capacity and strength.

Manufacturers are trying to diversify types of products

The market offers models with hydromassage, sitz baths, products on non-standard supports, different colors, with handles, wall-mounted, free-standing, shaped, and illuminated.

- Sitz bath . 120.140-70cm is ideal for installation in a room with a small area. The advantages of the product are that it can be used as a shower tray, it is convenient to bathe children, and there is more free space.

- Standard bowls . 150,160-70 cm are suitable for installation in almost all apartments.

- Enlarged 170-70.75 cm, requires space for installation. Large people are comfortable taking water treatments.

- Large bowls 180-80 cm or more. Installed in a bathroom of the appropriate size. The floor must be durable with high-quality coating due to its heavy weight (more than 150 kg)

- Designer models . They can be wall-mounted, free-standing, or corner. All kinds of shapes. The sizes here range from tiny to gigantic. It all depends on the imagination of the designer or customer.

As an example, Kohler released a corner bathtub, which no manufacturer before it could do.

The sizes of corner baths are from 90 cm to 200 cm. The product can be equilateral or asymmetrical. Many people think that such a bowl saves space - this is a misconception. It occupies the same area as the standard one. The advantage is that one of the corners at the installation site is freed up, which can be used for other needs. And as a bonus, it's still creative.

Of course, designer bathtubs cost several times more than regular ones.

Modifications

There are several main modifications of Soviet fonts. For example, corner structures are produced only at large enterprises. After all, production requires additional capacity.

Oval fonts are most often made on special legs. Such models are not adjacent to the wall.

The standard option is a rectangular bathroom with typical dimensions. It has rounded corners inside the bowl and high stability.

What is the weight of an acrylic bathtub, weight limit for different acrylic bathtubs

As a rule, a bathing container made by casting from real acrylic reliably withstands a weight of 500 kg. For example, if the volume of water in it is 300 liters, a person weighing up to 150 kg can swim confidently. Additional strength of individual bathtub models is provided by strengthening the bottom using a backing sheet. During testing, samples of cast acrylic containers withstood a load of 700 kg.

The maximum permissible weight indicators for various cast modifications are as follows:

- Triton Scarlet asymmetrical shape 1.67 m long - up to 450 kg;

- Triton Standard rectangular shape with a length of 1.70 m can support up to 500 kg;

- The rectangular Agata, 1.75 m long and 47 cm deep, is designed for swimming in a volume of water up to 280 liters, and can withstand a load of up to 0.5 tons without damage;

- The corner Aquanet Palau with a side length of 1.40 m, with built-in hydromassage, is designed for 440 liters of water. Withstands a total load of up to 600 kg;

- Corner Akrilan Laguna Vitel 140 with side, back and air massage, has a volume of up to 350 liters, can withstand up to 500 kg of total weight;

- Rectangular Aquanet West 150×70 with reinforced bottom – up to 450 kg.

Lightweight bathtubs made of laminated plastic and plexiglass have thinner walls, so they can withstand 50-100 kg less.

Important! Reliability and long service life of acrylic bathing containers depend on the quality of the materials used and their production technology. A real bathtub made of acrylic is not cheap, so before buying you should very carefully inspect it visually, touch it, study the technical characteristics, and consult with bona fide sellers. The vessel should not have a strong, repulsive odor, indicating the use of low-quality plastic materials.

Peculiarities

Soviet products, in addition to dimensions, have additional features. In particular the coating. After all, the quality of enamel affects the duration of operation and appearance during this period. The standard thickness of the enamel coating is one millimeter. In addition, the inside of the product is absolutely smooth, without cracks or chips.

The reliable design has the correct geometric shape. There are also no uneven edges, corners or folds. Safe operation is ensured by installing special armrests and handles. In addition, additional treatment of the bathroom with a special solution prevents corrosion.

The choice of colors is quite modest. Only now have technologies emerged that make it possible to bring any idea to life. During the Soviet period, the white model was the most common option.

How much does a cast iron bathtub from a European manufacturer weigh?

A cast iron bathtub with handles from a Finnish manufacturer, the Timo Tarmo model, has good characteristics, the size of which is 180x80x45 cm. The large rectangular bowl allows people of different sizes to use it. The features of the model are the snow-white color of the enamel coating, well-thought-out shape and proportion. Good quality enamel helps the product remain white for a long time. The width of the sides is 6 cm, the weight of the product is 148 kg, the volume of the bath is 230 liters. The price of the model is from 42 thousand rubles.

On the European market, manufacturers from different countries offer sanitary ware from economy to premium class

Cast iron bathtubs "Roka" are very popular among Russian buyers, because the models have an average price and high quality workmanship. The Roca Akira model from an Italian manufacturer, which is manufactured at a plant in Spain, has good reviews. The size is 170x85x44 cm, the kit includes a handle for more comfortable use. You can install the bathtub against the wall or decorate it in an original way inside a special podium.

The model can also be supplemented with two handles, the holes for which are made on the walls of the bowl. Another advantage is the central location of the drain, which makes it easy to adjust the filling of the bathroom without getting up. Dimensional characteristics:

- bowl volume – 225 l;

- weight – 115 kg;

- manufacturer's warranty – 10 years;

- height – 55 cm;

- the price of a cast iron bath is 39,500 rubles.

Foreign manufacturers present a wide range of cast iron plumbing fixtures

Which material is better?

During the Soviet era, cast iron was a popular material for the production of bathtubs. However, now they are made from various raw materials. In addition to cast iron, steel and acrylic are used. Each option has negative and positive sides. For example, steel is a fairly plastic material, which makes it possible to manufacture a bathtub of any configuration. The surface of cast iron is often porous, which leads to the accumulation of dirt and rust. This disadvantage is absent in steel models.

The weight of a cast iron bathtub is significantly greater than that of a steel bathtub, so its installation can be done alone. However, due to its small mass, the structure is unstable and needs support. The latter most often acts as a wall. Unlike a cast iron bathtub, this model heats up and cools down quickly.

The acrylic font is made of plastic synthetic material. Such raw materials are absolutely safe and hygienic. However, acrylic construction is most often not rigid enough. This indicator is regulated by the number of reinforcing layers. Therefore, to evenly distribute the loads, the bottom and sides of the bathtub are additionally reinforced.

The advantage of this model is the ability to maintain temperature for a long time. For example, a cast iron bathtub cools by one degree after five minutes. While in an acrylic bathroom such changes occur only after half an hour.

In this case, the acrylic font is easily damaged. Experts do not recommend using various chemicals to clean the product. It is better to give preference to special products that are designed specifically for such surfaces. By the way, small defects can be eliminated by polishing. Tools for this procedure are sold in hardware stores.

Which bathtub is better: cast iron, or acrylic, or steel?

Acrylic bathtubs have replaced steel and cast iron structures quite recently. Despite the fact that acrylic feels like plastic, its characteristics are durable. Thanks to its plasticity, heated acrylic can be used to make bathtubs of almost any shape, and after cooling, the finished product is reinforced and given rigidity.

The main advantage of steel structures is their low cost, but this does not mean that they are much worse than cast iron or acrylic bathtubs. A steel product, just like a cast iron product, after manufacturing is covered with enamel, which, during the drying process at high temperatures, penetrates into the micropores of the base. This makes enameled steel resistant to acids and abrasives. Bathtubs made of steel, just like products made of cast iron, are considered wear-resistant and impact-resistant.

Cast iron bathtubs, thanks to the enamel layer, look attractive, and the strength of the material guarantees that the shape of the bathtub will be maintained under any, even the highest, loads. Therefore, if you are wondering which bathtub is better: acrylic, cast iron or steel, it is worth considering that each product has its own positive and negative features.

So, a steel bowl has a lower weight, but cast iron retains heat better. Acrylic is elastic and can even withstand pinpoint impacts, while cast iron is damaged in this case.

Cast iron can maintain water temperature longer than steel, but not as long as acrylic

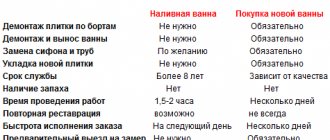

Acrylic bathtubs do not have as long a warranty as cast iron models. The table provides information regarding the advantages and disadvantages of different options to make it easier to understand the question of which bathtub is better: cast iron, acrylic or steel.

| Bath type | Positive characteristics | Negative characteristics |

| Acrylic | large selection of models; little weight; retains heat well. | There are difficulties in care; you cannot use abrasives for cleaning. Due to its plasticity, it can spring underfoot. Must be purchased complete with a protective panel or decorative trim |

| Cast iron | looks prestigious and expensive; reliable; has telescopic legs. | If a chip occurs in one place, violating the integrity of the product, this defect is difficult to correct. Difficult installation due to impressive weight |

| Steel | light; inexpensive; sustainable. | Does not hold heat well due to its thermal conductivity. Not very stable, will vibrate when connecting additional equipment. The bathtub fills up quite noisily |

Helpful information! Based on the characteristics of lower weight and practicality, acrylic bathtubs are considered a good option. However, the strength of cast iron makes it possible to use the product for a significant period of time. A steel bathtub is the cheapest, but it will be difficult to remove scratches from it.

Manufacturers

Relatively recently, specialized departments could not surprise with a wide range. At that time there were two manufacturers. Moreover, domestic and imported manufacturers differed not only in cost.

The weight of a 170 cm cast iron bathtub made in the Soviet Union exceeds its foreign counterpart by almost twenty-five kilograms. However, this is not a significant disadvantage. After all, such a difference is due to a decrease in quality and thermal conductivity.

In addition, the depth of imported models is only thirty-five centimeters. This is often not enough for the average person.

Domestic products are more durable, but the choice of bathtub shapes is small. Either it's foreign. The variety of design solutions, additional accessories and coatings is amazing and significantly increases the cost of the design.

Hard past

It is difficult to determine how much a cast-iron bathtub from the times of socialism weighs - the exact figure has changed over time. They gradually became lighter due to technological progress and the periodic struggle to save materials. It is known that in the 80s, a cast iron bathtub 170 cm long weighed 168 kg , but this weight was not a record.

And today you can encounter a situation where, in the course of replacing outdated plumbing fixtures, a team goes out to fight such a monster: only 4-6 adult men manage to remove it from the upper floors and load it for removal. When looking at such a scene, a thought arises: what is the situation with such products today? Isn’t it too difficult to equip a modern bathroom with a cast-iron container for water procedures? After all, it needs to be brought, raised to the floor, and installed. Will its mass outweigh the traditional advantages of such a bath - durability, reliability, thermal comfort during long relaxing procedures?

Advantages

Soviet cast iron baths have a number of advantages. In particular, the font is quite easy to care for. At the same time, the coating retains its original appearance for a long time. The use of household chemicals and temperature changes are acceptable here.

Manufacturers always provide a long guarantee for such a bathtub. It can be used for 25 years. The significant weight of the cast iron bathtub 170x70 eliminates most of the vibrations. For humans, they are practically invisible, but have a negative impact on the tightness of the joints.

Will the ceiling hold up?

The first thing that seems especially important when analyzing this issue is whether special measures are required to strengthen the floors when installing a cast iron bathtub? How many additional supports should be placed under the longitudinal crossbars? Such reflections seem especially relevant for amateur builders who are building a house with wooden floors without professional calculations from a specialist designer.

How much does a container filled with water weigh along with a person? The maximum value is about 700 kg . After calculating the point load on the floor, an approximate figure of 320 kg per 1 m2 is obtained. This value is quite acceptable for reinforced concrete monolithic and prefabricated floors that have a sufficient safety margin.

In the case of frame-type ceilings made of wooden load-bearing elements, you should think about reinforcement. Typically, such measures are carried out in conjunction with waterproofing work necessary for bathroom equipment.

Flaws

The large mass of the structure is its main disadvantage. For example, the weight of a 150x70 cast iron bathtub can be more than 100 kilograms. This creates certain difficulties during transportation. Therefore, you will have to use the services of several assistants, which leads to additional costs.

The disadvantages of such a product include an insufficient variety of shapes. Cast iron fonts are made rectangular or oval. This is due to the labor-intensive casting process. Relatively recently, designs have appeared that have an angular configuration. However, the cost of this option is quite high.

How to choose a bath, what you should pay attention to

- Coating. Smooth, even, uniform color, no bumps, chips, or cracks.

- Dimensions. Must match the footage of the installation location.

- Make sure that the product will easily fit through all doors and corners to the installation site.

- If the surface at the installation site is not even, it is worth purchasing a bathtub with fasteners (on legs)

- To avoid buying a counterfeit, ask for a product certificate and warranty card.

Cast iron is the very first material from which bathtubs were made on an industrial scale.

Until now, they are popular among consumers due to their undeniable advantages .

What is the first association that comes to mind when you hear “cast iron bathtub”? That's right, it's very heavy. Heavy weight is a distinctive feature of products made from this material.

If you are planning to choose and buy a cast iron hot tub or, perhaps, on the contrary, get rid of it, would it be a good idea to know how much it weighs? We will talk about this in detail in the article.

Installation

Installation should begin with placing the bathtub indoors. It must be turned over in advance in order to secure the leg parts. To do this you will need brackets and a set of tools. Next, install the siphon and drainage system. In this case, the structure must be located at a certain angle to the drain hole. You can adjust its position using the support part and the building level.

The contact points between the structure and the wall should be treated with a special protective compound. This must be done to ensure the tightness of the joints. Do not forget about installing a water shutter mechanism. After which you can begin to secure the outlet pipe.

In addition, grounding must be provided. After all, cast iron is a conductor of electricity. Before starting use, it is better to fill the bathtub with several liters of cold water. Only after this can you fully enjoy water procedures.

Bottom line

When purchasing an acrylic bathtub, consider its production technology, as well as all the nuances listed above. A modern acrylic bathtub will last you 5-7 years. Do not chase cheap offers, buy only high-quality acrylic sanitary ware from trusted manufacturers and do not forget about the rules for using the bathroom. After all, its service life directly depends on the correct use of plumbing fixtures (do not use detergents with acids and do not overdo it with boiling water).

Similar articles:

- Bathroom in English style

- Freestanding bathtub will decorate your interior

- Beautiful traditional bathroom with Burlington fixtures

- Choosing bathroom furniture

Weight of the bathtub with and without hydromassage

Weight of products made from pure acrylic of various brands, kg:

- 1MarKa Viola and Alpen Mars, 150x70 cm - 15-20. Standard rectangular shape.

- Cersanit Sicilia, 1.4x1 m - 20. Shortened model for a small bathroom.

- Jika Clavis, 1.7x0.7 m - 25.

- Santek Cannes, 1.5x1.5 m - 34. Luxury model: depth 0.47 (m). Designed for 360 l. There is a front panel.

With equal dimensions, baths can differ significantly in weight. Thus, a high-quality and durable Aquanet Extra bowl with dimensions of 170x70 cm weighs 17 kg. Its wall has a thickness of 4 mm, while that of Jika Clavis is 5 mm.

In the presence of hydro or aqua massage, the weight of the product increases by 1.5-2 times. For example, the weight of the 450 liter Triton Oscar model is half a centner.

Ways to strengthen an acrylic bathtub

A bowl with thin walls is installed in the frame. There are 2 options.

Factory frame frame

It is made by the manufacturer from a steel square pipe with an anti-corrosion coating and is supplied complete with a bowl.

Installed in the following order:

The bathtub is turned over and markings are applied on the outside of the bottom and walls for holes for fasteners, if they were not drilled by the manufacturer. The points are placed on thickenings specially designed for this purpose (mounting platforms).

- Make holes with a depth of no more than 6 mm. It is recommended to wrap electrical tape around the drill as a guide, leaving the specified distance from the cutting edge.

- Screw the frame elements using the fasteners provided by the manufacturer or completely similar ones. Self-tapping screws with other parameters may cause cracks in the product. Screwing is done by hand.

- Install drain fittings and fill the cracks with sealant.

- Turn the bath over and put it in place.

- By rotating the frame leg, raise the corner of the bowl to the required height.

- Based on the building level, other supports are adjusted. The side should take a horizontal position.

- Screw the hooks from the kit to the wall.

- They hang a bowl on them. Without this, the lightweight structure may tip over when trying to sit on the side.

- Connect the sewer.

- Fill the product with water to check the tightness of the connections.

- Install a decorative apron. It comes included.

Instead of an apron, you can build a screen from plywood and cover it with ceramic tiles.

Install on a homemade frame

You can make the frame yourself from the following materials:

- timber;

- rolled metal;

- bricks

The first option is the simplest, since the wood is easy to process and allows you to get by with common tools. Before assembly, it is impregnated with antiseptics and painted.

The metal frame is more durable, but more expensive. Assembly will require welding equipment.

The brick frame allows you to do without screwing the bowl to the wall. The master is required to have skills in masonry work. On the side of the communications supply, a gap of several bricks is left.

The design of the homemade frame should provide the gap between the floor and the bottom of the bowl necessary for installing the siphon.