The bathroom is the room where each family member spends part of their time every day, getting themselves in order in the morning before the work day or taking water treatments in the evenings, getting ready for bed. Plumbing plays a key role in arranging a bathroom, which is designed not only to facilitate hygiene procedures, but also to perform an aesthetic function, acting as an elegant decoration for the interior.

Stylish and ergonomic built-in sinks have all these qualities. How a sink built into a countertop in a bathroom differs from traditional sanitaryware analogues and what installation features should be taken into account when installing it, we will consider in the article.

Advantages

Built-in sinks in the bathroom are an ergonomic modification of washbasins. The fundamental difference is that the model is mounted on a tabletop in a cabinet.

Compactness is the main competitive advantage of a mortise product. The insert provides additional space, which is especially important for small apartments. The countertop provides additional space for placing hygiene items.

An undoubted advantage is ease of installation. Installing a sink into a countertop with your own hands does not require any special knowledge. Of course, if you have certain skills.

Countertop mounted bathroom sinks make bathroom design more creative.

Dimensions of overhead sinks

The dimensions of overlapping sinks are standardized to the perimeter dimensions of manufactured kitchen cabinets. The most common size of an overhead sink is 50x60 cm. The most commonly used overhead sinks (and, accordingly, cabinets) are sizes 50, 60 and 80 cm in various variations.

- 50×50 cm;

- 50×60 cm;

- 60×60 cm;

- 50×80 cm;

- 60x80 cm.

The width of the sink can be 50 or 60 cm (sometimes 55 cm), a size of 80 cm will be too wide and inconvenient to use (you will have to reach for the tap). The length of the sink varies in wider dimensions and depends on the presence of a monolithic countertop. If there is a table for dishes, then the length of the sink reaches 80 cm; if there is only a bowl, the length of the sink will be 50 or 60 cm.

The depth of the bowl can be 16, 18 and 19 cm, while the size of 19 cm will be more convenient for washing, since the walls of the sink will better limit water from splashing on the walls and clothes.

Double-bowl countertop sink

Classification

A built-in bathroom sink can be of two types.

- With a lower version – the model is placed and secured from below.

- With a top design - the bowl is installed on top.

There is no fundamental difference between the two types. The only difference is that the first option is considered more reliable. In addition to the fasteners, the built-in bathroom washbasin rests on the base with its sides.

The weak point of both structures is the joint areas. Craftsmen recommend treating the contacting sides with silicone sealant.

Mortise models differ in the shape of the bowl. The segment of built-in washbasins is divided into three groups:

- round and oval,

- non-standard,

- rectangular, square.

Non-standard shapes are made to order.

Material

Sanitary porcelain and sanitary ware are traditional classic materials for the production of mortise sinks for the bathroom. More than 60% of sanitary equipment is made from these mixtures. Sanitary porcelain differs from sanitary ware in the presence of mineral additives in its composition. Both materials are coated with a special glaze that provides resistance to mechanical stress. The popularity is easily explained in terms of quality indicators. The low level of porosity protects the surface from moisture penetration. Externally, sanitaryware is practically indistinguishable from sanitary porcelain.

Installation

The installation process is similar to that of conventional washbasins. To embed the sink into the countertop, you need to prepare the base. The step by step guide is as follows.

- Before embedding the washbasin into the countertop, we dismantle the old equipment. To do this, you first need to turn off the hot and cold water supply. Next, the corrugations and drainage elements are removed.

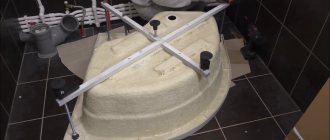

- Preparing the tabletop. Of course, the dimensions of the sink must match the cutout in the countertop. The small hole can be expanded. Place the shell on the surface and draw an outline with a pencil. Using the markings made, a hole is cut out for the built-in sink using an electric jigsaw. The hole for the faucet is drilled with a drill with a “furniture crown” attachment.

- The bathroom is a room with high humidity. Moisture may cause swelling. Therefore, treat the ends of the sawn part and the joints with silicone sealant. Be sure to sand and clean the edges before processing.

- A sealing rubberized tape is applied to the layer of sealant. The sink is carefully placed on the countertop in the resulting hole. The valve body is installed.

- Secure the fasteners with self-tapping screws. Apply silicone to the joints again. The goal is to close possible gaps around the perimeter.

- Connecting utilities. The stage is simple and does not require additional explanation. The main thing is to carefully tighten the threaded connections. After installing the sink into the countertop and connecting it, check for leaks.

Designer models

This type has little functionality, pursuing design goals. They are installed for decoration or cooling drinks. They are made of different materials: copper; bronze; glass; wood; stone.

This is one of the popular models for the kitchen. The advantages include:

- simple installation;

- democratic price.

The disadvantages are the gaps between the walls of the cabinet. Installing overhead sinks is considered a simple job, especially with standard module sizes.

This type of sink is more suitable for kitchen sets consisting of separate modules; they are easily installed in corner kitchens with standard dimensions.

Kitchen sink made of artificial stone

Criterias of choice

Let us remind you that the product range includes four groups of products:

- Built-in below the tabletop.

- Built in from above.

- Semi-recessed.

- Universal.

There are a number of characteristics common to all types of products. In addition to the material and shape of the product, these are:

- dimensions – height, depth, width;

- presence or absence of a pedestal;

- equipment - bottom valve, siphon, drain-overflow;

- installation method - to a cabinet or to a tabletop.

Built-in sinks: what are they?

Built-in sinks are those that form a single whole with the countertop. Based on the type of installation, they can be divided into two groups. The first category includes the so-called overhead or top-mounted devices.

During installation, they rest with small sides on the edge of the installation hole cut in the tabletop. As a result, a noticeable seam is formed, which requires special attention, since if not properly cared for, mold or mildew can form here

If installed incorrectly, moisture may enter the tabletop through this seam, which will lead to rapid destruction of the base. At the same time, overhead models are easy to install and relatively low cost.

The second group - integrated (or built-in from below) models - are inserted into the base and secured from the inside with special fasteners. They become a kind of continuation of the tabletop. This is a more aesthetic option, however, its installation is a little more complicated and the cost is higher.

When purchasing a sink mounted into a bathroom countertop, you must pay attention to what material it is made of, since its performance characteristics and installation method will depend on this. Let's consider what material is used for the production of plumbing fixtures.

Ceramics

The material is baked clay. You need to know that, depending on the manufacturing method, a ceramic sink can be porcelain or earthenware. The first option is more fragile.

At the same time, it is distinguished by greater uniformity and density than earthenware. Porcelain is easy to clean, dirt does not stick to it and it is more beautiful. Its cost is slightly higher.

Porcelain shells are sometimes painted with colored paints, photo printing or ornamentation. The result is a unique bathroom decoration

Budget sink models are made from faience. This is a relatively inexpensive material that is more durable than porcelain. The main disadvantage of earthenware is its high porosity. Pollution easily penetrates the pores and lingers in them, so it is quite difficult to care for the material.

In addition, over time, small cracks may appear on the earthenware, which gives it a vintage look, but affects its strength.

Metal

The traditional material for making sinks is stainless steel. However, such products are usually not chosen for the bathroom, unless they are selected to match the tray in the shower stall or bathtub.

Sinks made of non-ferrous metal, simulating copper or bronze, will be more appropriate in the bathroom. Such models will fit perfectly into a Mediterranean or rustic style.

A metal built-in sink is an excellent solution for bathrooms decorated in techno, hi-tech, loft or even modern style

Metal sinks have many advantages. They are strong and durable, quite resistant to various mechanical damage. Their weight is relatively light, so installation is not difficult. At the same time, the products have a very attractive appearance, especially antique-style models. Disadvantages include difficult care and high cost.

Natural and artificial stone

Natural materials most often used are marble, basalt, travertine, granite or onyx. All stone sinks are very beautiful, durable and environmentally friendly. However, the cost of such products is high. This is due not only to the price of raw materials, but also to the complexity and labor-intensive process of processing natural stone.

The sinks are very massive, which makes installation much more difficult. The material has a high density, so dirt is not absorbed into its surface

Only special products can be used to care for products; acids and abrasives can damage them.

Artificial material has all the advantages of natural material and even surpasses it in strength. It consists of about 80% stone chips, which are bound by a special polymer. The result is very strong and durable products that are also easy to maintain. Their prices are more affordable.

Glass

The products are made from special tempered glass, the strength of which is sufficient for trouble-free use of such a sink. The glass surface of the equipment is resistant to mechanical damage and is almost impossible to scratch.

In addition, the high density of glass prevents dirt from being absorbed into the surface. The products are insensitive to temperature changes and aggressive chemicals.

Glass built-in sinks are very beautiful. They can be transparent or tinted. Colored glass embedded in a transparent tabletop looks especially good

Glass sinks are very attractive in appearance. They can be produced in a variety of colors, transparent or tinted. The shape of the product can also be any, even the most unexpected.

The owner can be inconvenienced by stains and water marks remaining on the glass, but the use of special cleaning products easily solves this problem. For transparent sinks, special chrome-plated components are used.