Photo by ReRooms

Bath in the ReRooms project

Remember that the bathtub will take up a significant portion of the room, so it is important to accurately measure the area where it will sit. Please note that space is required for other accessories and fixtures. Measure the doorway to make sure you can fit the tub in.

Calculate the exact cost of repairs using an online calculator

and receive a free detailed estimate for repairs

Calculate

Photo by ReRooms

Corner bath in the ReRooms project

Choosing a bathtub is a very personal matter, so don't let anyone else make that decision for you. Yes, a contractor can help you size the tub in relation to the space and advise you on installation, and a bathroom designer can help you with style, but you should choose a tub that you'd be happy to use every day. You can “try on” the model you like right in the store. Feel free to climb into the bathtub, lean back at full length and see how comfortable you are. Some bathtubs look great but can be very uncomfortable. Do you like to sit or do you prefer to lie down with your legs fully extended? Do you want your feet to reach the end of the bath without your head going under the water? Do you have children who will also use the bathroom? Do you need armrests or grab bars? Pay attention to the slope under your back and the height of the bathtub. Height helps determine where the faucets will be placed, at what level the tiles will be laid, and whether you need to recess the bathtub slightly into the floor or install a non-slip step so that you can get in and out of the bowl without difficulty.

Photo by ReRooms

Bathtub with cladding in the ReRooms project

Advantages

An oval bathtub is a kind of intermediate option between rectangular and non-standard models. The latter are still considered by most people to be quite a curiosity.

This model is more compact than various bulky square or round bathtubs. This allows you to install an oval bathtub even in a small room.

An oval bathtub, of any model, can be found in any plumbing store. The differences between the products lie in both materials and design features, as well as installation methods.

Dimensions and dimensions

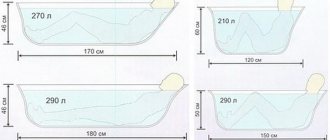

Regular rectangular ones are available in standard sizes:

- length – 180, 170, 150, 130, 120 cm;

- width – 80, 75, 60 cm;

- height – 62.65 cm.

If possible, you should select a model that matches the height of the tallest member of the family, otherwise he will have to accept it with his knees bent.

Currently, many new models are being released with sizes that differ from the standard ones.

The dimensions should be comfortable for all residents of the house, and also correspond to the space of the bathroom

Flaws

The oval shape of the bathtub is non-standard, which is why the price tag for such a bathtub is significantly higher than for a simple rectangular one. On the other hand, this same price tag is also determined by the brand and material, so even a not very rich person can choose an option that suits their pocket.

Although the oval bathtub itself takes up quite a bit of space in the room, its installation requires slightly more space than is ultimately freed up. Therefore, before replacing the old bathtub with an oval one, it is necessary to carefully measure everything again.

Materials

- Cast iron. Surprisingly, oval cast iron bathtubs are in fashion. The reason for this is that antique and retro styles are now gaining popularity. For decades, cast iron bathtubs have been a model of reliability and durability. They also perfectly insulate sound and take a long time to heat up and cool down. The main disadvantage of cast iron bathtubs has not gone away - they are very massive and of considerable size.

- Steel. Bathtubs made of steel are the most budget option of the lowest quality. Therefore, it is chosen only by those who cannot afford anything else. They are not inferior in design to any other bathtubs, but they are much less convenient to use. A steel bathtub has a slippery and brittle coating and extremely high thermal conductivity, which is why it heats up and cools down very quickly. Another disadvantage is that when water is collected, this process is accompanied by a loud and unpleasant noise.

- Acrylic. Acrylic is a modern synthetic material. It has all the advantages of analogues created by Mother Nature. This material is light and flexible, like steel, retains heat and absorbs sound no worse than cast iron, and also looks no worse than marble. Its only drawback is its fragility, which is why the bathtub will have to be replaced soon after purchase.

- Marble. More expensive than the others are probably marble bathtubs. The only exceptions are products made from rare wood species, but those are made to order. Bathtubs are made from natural or artificial (cast) marble. Moreover, it is more profitable to take a bathtub made of artificial marble: it looks great, and its cost is noticeably lower. Also, caring for an item made from cast marble requires much less effort than something made from natural raw materials.

Additional options

Baths can have various additional options for massage and other amenities. Let's look at some popular additional features of bathtubs.

- hydromassage - water from special nozzles is supplied under pressure, providing a massage to the person lying in the bathtub, the intensity can be adjusted;

- aeromassage - air acts as a massager;

- Jacuzzi - massage is carried out with both air and water at the same time;

- lighting - beautiful lighting in the bathroom;

- radio – a radio is built into the bathtub.

In the modern world, the buyer can choose products to suit every taste and budget. Bathtub types vary and you need to weigh your options. Of course, bathtubs made from various materials have both their positive and negative qualities, so the choice of a specific model remains up to the consumer.

Design

The oval shaped bathtub is a truly versatile piece. It will fit perfectly into any design, and all that is needed is to choose the right model. For example, for an oriental style, an oval bathtub with a copper finish is good, and in order to create a bathroom of a minimalist Japanese design, it is best to choose a white acrylic bathtub.

There are various options for installing an oval-shaped bathtub. Placed in the center of the room, it will attract all attention, which should be used if you want to make the bath the main piece of furniture. It will also look good on the edge of the bathroom - in a corner or near a wall. But it is recommended to install the bathtub separately from other plumbing fixtures: this is how it will look best.

Dimensions

The standard dimensions of oval bathtubs are approximately the same as their rectangular counterparts. The most commonly purchased products are 170 by 80 cm. The largest size of such a bathtub is 240 by 150 cm, its volume is 530 liters. The smallest bathtub measures 120 by 70 cm. You can find oval bathtubs for one or two people.

Bowl shape

If the bathtub is oval-shaped, then its bowl is usually also oval. All other configurations have a negative impact on capacity. On the other hand, a large bathtub may have a slightly different shape. For example, oval bathtubs with a rectangular bowl are in second place in popularity. On sale you can find oval bathtubs with bowls of irregular shape, not too far from the oval: having smooth lines and rounded edges.

Bath place

One of the advantages of an oval-shaped bathtub is that it can be installed anywhere. And the design of a room of a sufficiently large size, if its communications are carried out exclusively under the floor, can be improved by installing a bathtub in its center. If the room is not spacious, you can install a corner model in it. It is more difficult if you need to install the bathtub close to the wall: a considerable gap is inevitable here. But here professionals can recommend an excellent way to deal with this problem: you just need to create a niche that completely follows the contours of the bathtub.

You can install an oval bathtub using various methods. They are often placed on decorative legs. And if the bathtub is a huge solid bowl, it is installed directly on the floor. It is more difficult and more expensive to install a bathtub into the floor or place it on a special podium.

Making acrylic stronger

Acrylic is an ideal material for making products of the most complex shapes . The best bathtubs are made of cast acrylic, preferably reinforced with steel mesh. It is produced by polymerization of polymethyl methacrylate (PMMA) poured into molds using the vacuum molding method. The high cost of the material has led to alternative solutions. Two of them are extruded acrylic and co-extruded acrylic, i.e. combined ABS/PMMA plastic, where ABS is acrylonitrile butadiene styrene. Even from the name it is clear that this resin contains extremely toxic styrene. In such baths, the proportion of acrylic (PMMA) is 5-10% of the total thickness (from 0.18 mm to 0.09 mm).

Sheet ABS /PMMA is obtained using co-extrusion, when heated, softened sheets of polymers are combined in the polishing head of the mechanism, from where they are extruded in the form of a monolithic plate with a top (acrylic) and a bottom (plumbing plastic). Then the combined plastic is heated again and in a mold under vacuum (vacuum thermoforming method) a beautiful, shiny bathtub blank is squeezed out of it, which does not require further polishing (cast acrylic “purebreds” have to be polished).

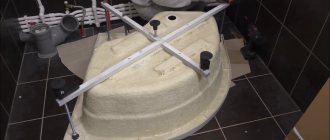

The “trough” turns out to be very thin (from 0.3 mm), and of uneven thickness. The thickest part is on top along the edges of the future bathtub, the thinnest part is on the bottom along the bend. It is given strength in various ways.

The simplest option is to apply polyester (putty) resin (it is cheaper than epoxy) with cut fiberglass. More reliable is to glue glass mat or fiberglass with epoxy or polyester resin, preferably more than one layer. see the number of layers at the top, along the cut edge of the bathtub.

Then the bath is heated in an oven for 10 hours to remove residual styrene from the resin and relieve internal and external stresses. When this production step is skipped, the store's bathtubs stink of chemicals. Decent manufacturers care about the health of customers and paint over these potentially dangerous resins with safe paint.

Even better rigidity of the bathtub is given by polyurethane applied on top of fiberglass reinforcement. Previously, soft polyurethane was used, but now it is very hard. Some manufacturers glue pieces of chipboard (sawdust glued together with resin) under the bathtub to add rigidity to the structure.

You must understand that if it says “100% cast acrylic,” this does not mean that it is a cast bathtub. It is made in the same way as from combined plastic, but without sanitary plastic, i.e. extruded acrylic. The trough is “blown” from block acrylic (“cast acrylic”, “sheet acrylic”, “pure acrylic”).

Continuous cast acrylic - a melt of plastic is poured onto an “endless” sheet of stainless steel. Its quality is worse than that of block, so it is intended for the manufacture of shower trays. To save money, they can also make a bath out of it.

In any case, the sides of acrylic bathtubs are more rigid and bend less, but chips are more likely to occur from impacts. Combined plastic bends better, springs back under impacts, and if a chip occurs, it is small, but many radial cracks form around it, which are not easy to repair reliably.

By the way, all Russian “acrylic” troughs are made only from an ABS/PMMA sandwich. Manufacturers present it as multilayer plastic.

There are imitations of cast acrylic bathtubs. After the metal shower falls, it is clear that the acrylic layer is less than 1mm, and underneath is transparent plastic or gray concrete.

Hybrid of steel and plastic

An acrylic bath option is a hybrid of steel and plastic. Such a sandwich consists of 3 layers - acrylic on top, underneath there is a layer of about 1 cm of special material to compensate for the expansion coefficient and delamination of the product, and an iron trough at the bottom.

To summarize, bathtubs and shower trays are made from four types of acrylic: 1) ABS/PMMA (Combined plastic); 2) Block acrylic (“100% cast acrylic”, sheet acrylic, PMMA); 3) Acrylic continuous casting; 4) Cast acrylic bathtubs. Quaryl is a mixture of acrylic and quartz sand.

Acrylic concrete

( Quaryl ) Quaryl from Villeroy & Boch (Germany). The surface of the quaril bath is not polished, but varnished. The grains of sand are rounded and enclosed in an acrylic shell; quarikast. The space between them is filled with acrylic.

Quaril at the fracture seems to be a homogeneous plastic, no sand is visible. Bathtubs made from this material are practically indistinguishable from cast acrylic ones; they are cast and polished in the same way. It is harder than cast acrylic, but more brittle. The cast acrylic bathtub has a bottom thickness of about 25 mm and sides of 6 mm. Quaril baths, due to the fragility of the material, have to be made much thicker, the sides are approximately 10 mm, and, accordingly, heavier.

There are several similar materials:

- English QUARRYCAST , volcanic limestone with acrylic)

- WhiVe ® from Albatross contains a ridiculous 2% acrylic. 98% of the material is a mixture of natural mineral elements.

- The American company DuPont® produces Corian - a mixture of natural ingredients: clay, acrylic resins, aluminum trihydrate, natural mineral fillers and pigment additives.

- I had a chance to test a pallet made of an unknown composite material RWS . The description is not available on the official website of the manufacturer Devon&Devon. Sellers report various things: acrylic, cast acrylic, plumbing acrylic, hardened acrylic, polyester resin and aluminum in a ratio of approximately 1:2 and is monolithic with the same chemical composition throughout the volume. No chemical analysis was carried out. Field tests have shown that the product easily absorbs rust and is dissolved with alcohol, which does not damage acrylic and cheap polymer concrete. The pallet is not reinforced inside. The consequences are visible in the photo.

When buying a plastic bathtub, you need to know that you can run into hidden or even disguised factory defects in acrylic bathtubs.

- Sometimes the plastic on the bathtub is so thin that the dark reinforcing layer shows through. At the factory, such stains are simply touched up.

- I bought a bathtub (shower stall), installed it, removed the film from the tub and saw that the plastic was deformed and began to bubble.

- The bottom is flat, but there is empty space underneath. Over time it will break.

- It happens that a plant will purchase a batch of plastic sheets (ABS/PMMA or PMMA) to which insufficient plasticizer was added during production. Even if you make a bathtub out of them following all the technological steps, then in a month or six months it will crack at the drain and (or) overflow. The troughs can crack if the enterprise does not follow the production technology.

- In 2012, counterfeits of Duravit acrylic bathtubs appeared on the St. Petersburg market. In appearance, they do not differ from the original ones. If you rub a little with solvent, the white paint is washed off, and some kind of gray plastic is found underneath it.

- There are Chinese acrylic bathtubs where white acrylic is painted with colored paint, such as mother-of-pearl.

There is no point in asking anything about the quality and thickness of the plastic in the store. The sellers either don’t know anything themselves or are blatantly lying about 6-8 mm. acrylic thickness.

Useful tips

- People who have purchased an oval bathtub have noticed that waterproofing such an item is not an easy task. The purpose of this sanitary fixture is for bathing and relaxing, not for showering. So for those who value speed in hygiene procedures, it is better to buy not only a bathtub, but also a shower enclosure;

- Before purchasing a bathtub, you should look at its contents. Most manufacturers include a headrest, handrails and a hydromassage panel. However, the cheapest models may easily not be equipped with them, and you will have to buy additional accessories yourself;

- If you have a thick wallet, you can pay attention to built-in bathtubs equipped with a countertop. Such plumbing fixtures are distinguished by both great efficiency and considerable practicality. This is due to the fact that you can put a washcloth and various detergents or cosmetics on the countertop while bathing.

- Using the front panel, you can either hide the connections and plumbing fixtures, or complete the design of the structure. When choosing a panel, you must be guided by the individual characteristics of the bath. More specifically, the style, color scheme, as well as the material from which the product is made.

Bath by Marco Tallarida

Designer Marco Tallarida has designed a unique bathtub that follows the contours of the human figure. This model is very practical, original and even changes perception thanks to its creative design - wooden frame and smooth lines. The bathtub is also equipped with a special comfortable headrest. By the way, this example of taste and charm even received the Bathroom Innovation Awards.