They replaced the massive, clumsy and uniform washing containers of the Soviet period. They immediately appealed to customers who were not spoiled by the variety of the model range.

However, during the operation of steel bathtubs, it turned out that the noise that occurs in them when drawing water can be heard even through 2 floors, and the water in it cools down very quickly. The low price partly compensates for this defect in the products, but it is difficult to put up with such discomfort in everyday life, especially if there are small children in the family. But experienced craftsmen believe that the noise of steel bathtubs is not a reason to refuse to buy them, because you can eliminate this defect with your own hands, using inexpensive improvised means.

Advantages and disadvantages of steel containers

: expensive and heavy, replaced steel and. A steel alloy bathtub is the best option for replacing an old bathtub. However, many people still do not trust steel bathtubs. This attitude towards this plumbing equipment has developed due to the fact that the sound insulation of a metal bathtub made of a steel alloy is low.

But this is a minimal drawback of a steel bathtub, which can be easily and simply eliminated. A steel bathtub has many advantages, which are a strong argument in favor of choosing steel structures.

The advantages of steel bathtubs are:

- Low cost of equipment compared to acrylic and cast iron bathtubs,

- Durable coating of enameled surfaces,

- Rapid heating of metal

- structural stability,

- Easy to deliver, move, install and dismantle,

- Possibility of different fastenings,

- Modern varied design and size.

Some people consider the following to be disadvantages:

- Low sound insulation of a steel bathtub,

- Rapid heat loss.

Sound insulation and insulation of a steel bathtub

However, many do not think about the fact that there are many possibilities and ways to easily, simply and quickly eliminate these shortcomings with your own hands when installing a container. A number of measures to eliminate noise and heat loss can be applied in advance of installation. And this will make the steel bathtub quite competitive, not inferior in its performance data to other structures of this type made of acrylic and cast iron.

Soundproofing a steel bathtub with your own hands is a simple manipulation, inexpensive, accessible and does not require special skills.

When purchasing imported equipment of this type, many paid attention to the presence of rubber or rubberized pieces of special material glued to the bottom of the bathtub. It is this material that is able to retain heat and absorb noise and splashes of water.

The process that makes the insulation of a steel bathtub complete is based on this principle of sound absorption.

So, there are several simple ways to eliminate hum and retain heat.

Vibroizol

Alternative methods of insulating a bathtub relative to foaming

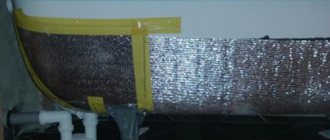

In addition to foaming the bathtub, there are other alternatives to noise and heat insulation of the bathtub. So, for this you can use polystyrene foam, gluing it with sealant or the same thing. You can use specialized sound insulation for cars, on a self-adhesive basis.

In the end, no one limits you in your own imagination and perhaps you will offer the world something simpler and more effective. But the essence here is the same for all options. Increase the thickness of the bathtub wall, select a layer of sound-heat-absorbing material, and also, if possible, increase the rigidity of the structure of the bathtub itself. Now that you know everything for sure, you can definitely foam it or choose something similar to make your bathtub better in its performance properties, with minimal investment.

They replaced the massive, clumsy and uniform washing containers of the Soviet period. They immediately appealed to customers who were not spoiled by the variety of the model range.

However, during the operation of steel bathtubs, it turned out that the noise that occurs in them when drawing water can be heard even through 2 floors, and the water in it cools down very quickly. The low price partly compensates for this defect in the products, but it is difficult to put up with such discomfort in everyday life, especially if there are small children in the family. But experienced craftsmen believe that the noise of steel bathtubs is not a reason to refuse to buy them, because you can eliminate this defect with your own hands, using inexpensive improvised means.

Vibroizol

In shops and supermarkets, in markets specializing in the sale of auto parts. This is where you can find the Vibroizol material. This is a specially developed material with a unique composition, which is intended for use in the automotive industry. With its help, many car enthusiasts restore the sound insulation of their car. Vibroizol is based on bitumen and a rubberized base. One side of this material has a strong adhesive composition.

Note!

This composition adheres tightly to any smooth surface at any air temperature.

If Vibroizol perfectly eliminates noise in the car interior, then it will perfectly cope with its task in the bathroom - it will eliminate unnecessary sounds. To do this, the outer part of the bathroom is covered with this unique material. It is possible to treat with Vibroizol only the areas where water falls into the container from the tap and the area where the human body comes into contact with the bottom and some of the side walls of the bathroom. This will reduce the hum and noise of the water jet and help retain the heat of the container walls.

Polyurethane foam

The question often arises - how to thoroughly insulate an iron bathtub. The answer is quite simple - you need to use ordinary construction foam. Exactly the foam that is used to seal windows and doors.

The bathtub container is turned over and a layer of polyurethane foam is slowly applied. The foam is applied to a previously degreased surface. To do this, treat the outer part of the bathroom with an alcohol-containing composition. For convenience, the bathtub is turned over from its legs onto the sides of the container, placing it on a soft surface to prevent accidental scratches. The polyurethane foam is applied evenly, in a continuous layer, without gaps. To prevent the foam from draining, the layer is applied slowly, and the bath is turned from one side to the other as it is covered with foam. But only after the foam has dried.

To enhance the sound absorption effect, you can additionally use polyethylene film. It is best to use polyethylene, which is intended for forming greenhouses. It is dense, elastic, inexpensive. After applying the foam, a previously prepared piece of film is applied to its surface. He presses his hands against the foam, forming a “crust” on the area, similar to a shell. This will be additional insulation.

Noise insulation with polyurethane foam

When treating the outside of the bathroom with polyurethane foam, you should follow some rules:

- Foam should be used indoors.

- Foam for use in summer is more practical, as it is resistant to high temperatures and swells better.

- In order for the layer to be uniform, without sharp bumps, gaps and stacks, it is necessary to use a special nozzle for applying foam. Usually a special “ ” is used.

- In order for the foam output to be as large as possible and at the same time economical, you should heat the foam container under running hot water and shake it thoroughly.

- The place where the siphon is installed and the part adjacent to it should not be covered with a layer of foam. Since this place must be accessible when changing the siphon.

- The overflow area should be left free.

- It is imperative to pay attention to the terms of use of polyurethane foam, since this product loses its performance properties after the expiration date.

There are different ways to soundproof

Other ways

There are some other ways to insulate a steel bathtub. Often a steel bathtub is installed on a pedestal and then covered with slabs or bricks. Then lay tiles on top. This method of installing a bathtub helps improve sound insulation, but also provides the opportunity to fully retain heat. But if you cover the bathtub with an additional layer from the inside of the wall, you will be able to correct the situation.

There is a method of increasing thermal insulation using technical cork. This method is more expensive, but the most environmentally friendly.

Note!

With this method, the fire safety and moisture resistance of the structure are high.

The technical plug is applied according to the instructions.

See inaccuracies, incomplete or incorrect information? Do you know how to make an article better?

Would you like to suggest photos on the topic for publication?

Please help us make the site better!

Leave a message and your contacts in the comments - we will contact you and together we will make the publication better!

It often happens that you really want to update the plumbing in the bathroom, but finances do not allow you to spend money on a good cast-iron or thick-walled acrylic font, or maybe even. In this case, usually, steel bathtubs or inexpensive thin-walled acrylic ones are purchased.

Everything would be fine, but metal products have two very unpleasant problems: high thermal conductivity (water cools quickly) and poor sound insulation (very loud sound from a jet of water).

But don’t be upset, during the installation process it’s quite easy to get rid of these disadvantages, there are many ways to insulate and soundproof a steel bathtub, but today we will focus on the simplest and most affordable - heat and sound insulation using polyurethane foam (polyurethane sealant).

In cheap acrylic hot tubs, these shortcomings are expressed, of course, to a much lesser extent, but the insulation of such products will not be superfluous.

Types of baths that need treatment

The following design options can be purchased at any plumbing store:

- Products made of cast iron are highly reliable and have a long service life. Repairing the structure is difficult. This is due to the large weight of the bath. Moving it from place to place is fraught with many problems. It is difficult for a small team to cope with this, not to mention the efforts of one person.

- The steel product weighs little, making it easy to install. The cost of the products is low. On the market you can find options of different shapes and sizes.

A steel bathtub has low sound insulation and does not retain heat well. To improve these characteristics, the bottom of the special structure is treated with polyurethane foam.

- Acrylic has a low degree of thermal conductivity. The surface of the structure does not slip, which ensures the safety of the product. Acrylic breaks easily if you hit the surface too hard. During use, scratches appear on the plumbing fixtures that spoil the appearance.

Each person will be able to choose the most suitable option for themselves. If you have any difficulties, consult the seller or read the instructions for use.

Material selection

Is it possible to use polyurethane foam in the bathroom? Yes, but the main condition when choosing it is the presence of moisture resistance

.

After all, condensation from hot water will gradually accumulate on surfaces, and if the selected sealant is not resistant to moisture, it will quickly shrink and become unusable.

You also shouldn’t skimp on the manufacturer, because you only need 2 cylinders to operate.

If you look for a cheaper sealant, you will only win 100-200 rubles, but there can be many problems with low-quality foam. Up to the need for its complete replacement. It will also be much more convenient to use it with a special pistol.

What tools are needed?

To perform the work efficiently and correctly, you will need the following list of tools and materials:

- 2 cylinders of polyurethane foam;

- degreaser;

- spray bottle with water (to wet the surface of the bowl);

- knife (for cutting off excess);

- foam gun;

- respirator (foam vapors are volatile, it is better to protect the respiratory tract).

Instructions on how to properly foam a steel hot tub?

Typically, this method is used to soundproof steel bowls, but it can also be used for acrylic bathtubs.

Be sure to read articles about other methods and soundproofing of bathtubs.

STEP 1.

Place the bathtub upside down on the floor. Don’t forget to first place pieces of cardboard underneath it so as not to scratch the enamel surface.

STEP 2.

Be sure to thoroughly wipe off dust from the surface on which you are going to apply the foam. Then you need to degrease it; for this you can use a universal degreaser, alcohol or dishwashing detergent.

STEP 3.

It is better to prepare the container before use.

It needs to be shaken well and heated a little by placing it under running warm water for 5 minutes. It would be enough. Under no circumstances should you heat the cylinder in a kettle or boiler, as many resources advise.

Due to a significant increase in pressure, it can explode. STEP 4.

Spray the bath generously with water using a spray bottle. This way the foam will stick to the surface much better. If the bowl dries out during application, repeat the procedure.

STEP 5.

Place the can on the gun and get to work.

It is better to apply the foam in dense layers using a snake. Start with flat surfaces and gradually work your way up. There are no special recommendations for the sequence of surface coating. It is important not to leave any gaps. Sometimes the drain needs to be replaced, so it's best to leave a little space around the hole.

STEP 6.

Now you need to leave the font until completely dry for 5-6 hours. After the foam has completely dried, cut off any excess foam where the legs are attached using a knife.

Installation of an acrylic bathtub

Installation of an acrylic bathtub goes through 4 main stages :

- Bathroom assembly.

- Insulation of its location.

- Installation, coordination of all parts, strengthening of the bathroom.

- Connecting the bathtub to the walls, checking the operation of the bathtub in a complex of all elements.

First, we prepare a place in your bathroom - it should, first of all, be comfortable for you. Having verified all the aesthetic aspects, we will proceed to the technical part of the installation, which is a rather complex installation process. Violation of which can lead to breakdown and reduction in the service life of the bathroom, so we carefully read the instructions and study unclear points on the Internet.

Bathtub installation: product assembly

Once again we check the integrity of the product and the presence of all components: remove the film and check the presence of parts with the list in the instructions.

Let's start with the support structure , the platform on which the bathtub will be placed and which will ensure the stability and correct positioning of the bathtub - the legs. Installing the legs is considered a fairly simple operation. To do this, we need to connect two pipes with holes with nuts, studs, screws, washers and plastic heels. All this is assembled into a structure on which the bath will be placed. This is the supporting structure of the bathroom and must be assembled carefully, piece by piece.

When the structure for securing the bathtub is assembled, using the self-tapping screws that are included in the kit, we attach the pipe to the bottom of the acrylic bathtub. It is very important to do this carefully so as not to make a hole in the bathtub, preferably using a screwdriver. Self-tapping screws are screwed into the sealed part of the tub , which can be found at both ends.

During self-assembly, it is important not to use unnecessary force and not to confuse the parts.

When installing a bathtub, many craftsmen do not limit themselves to assembling a supporting structure and installing the bathtub on it, but install it on a solid base, which is made of brick and cement . Therefore, this option may also be quite appropriate.

If the bathtub is sold without legs, then it is installed on a brick frame , which must be built at the base of the bathtub so that it does not interfere with the siphon. The option with installation on a brick base is considered more reliable. To install the base under the bathtub, you can make a solution from ordinary cement.

Next, you need to turn the bathtub over and proceed to the process of installing the siphon, which we carefully check and screw in firmly.

Installing an acrylic bathtub begins by placing it in the designated area and aligning its edges to the same level. We align the bathtub along a straight line and make special marks on the wall, which are intended for mounting hooks.

In accordance with the designated points, we screw the bolts into the wall and attach the brackets . Our bath will be located on them. It is important to verify the exact location of the bathroom, without distortions, because if the placement is not accurate, the acrylic will begin to deform and sag over time. Also, you should not deliberately tilt the bathtub so that there is a drain, since it is already provided for in every design.

We place the bathtub on bricks or on a structure, strengthen its bottom and, using polyurethane foam, spray the gaps.

Bath insulation

In order for an acrylic bathtub to retain heat well, installation experts recommend turning to the process of insulating its bottom using foam:

- We turn the bathtub over and apply foam in a thin stream to the entire surface of the bottom, let it dry.

- It is also important to foam the legs of the bathtub to make it easier to withstand the additional load.

After the foam has dried and the bathtub is installed in place, it is necessary to spray the joints between the bathtub and the wall with silicone. Now you need to wait until the silicone dries. This is at least 6 hours , some masters recommend leaving it to dry for up to 12 hours.

Checking readiness

At the stage of completing the installation, it is necessary to carefully check the structure, look at all the joints, and let the polyurethane foam dry. After this process, fill the bath with water . Again we check that there are no leaks anywhere, and let the bath stand filled.

The bathtub is assembled, the sewage system is connected - we proceed to install the panel - screen on the bathroom: we put a special latch on each leg and connect it to the panel.

You have a new bathtub in your apartment - congratulations, you did it yourself!

As you can see, an acrylic bathtub allows the owner not only to choose an interesting design for himself, to some extent even to look for interesting unique shapes , for example, corner bathtubs, and due to its lightness, such a bathtub also allows you to install it yourself. You can be sure that the choice is made correctly.

a real relaxation corner at home that suits you, create your own personal space for deep relaxation and release from problems and stress.

conclusions

We looked at a very effective way to soundproof a bathtub. The main advantage of this method is its simplicity and low implementation price. We hope it will help improve your comfort when using plumbing fixtures.

The most popular products on the plumbing market are steel bathtubs. In some ways, they can be called budget class, since their price is relatively low.

However, with proper handling, such products can boast a very long service life.

At the same time, the owners of such bathtubs note a couple of serious shortcomings.

- Firstly, the water in them cools much faster than in their cast iron counterparts;

- and secondly, a very loud sound is made by the stream of water gathering, which can be heard not only in neighboring rooms, but also in apartments.

And these shortcomings can negate the main advantage of such baths, namely, low cost.

However, this is not such a problem, because both the noise and the rapid cooling of the water can be forgotten once and for all if the steel bath is properly insulated. This will be discussed in this article.

Difference from cast iron baths

Acrylic bathtubs are very attractive due to their weight , which is about 30 kg. At the same time, in terms of strength and reliability, they are not much inferior to cast iron bathtubs. If such a bathtub gets scratched or chips appear on it, you can use a special paste and restore it at home, which cannot be said about cast iron, the repair of which is costly and problematic.

Cast iron bathtubs are more durable , but the bathtub itself is very heavy compared to acrylic bathtubs and does not have as many design solutions that can be applied to acrylic bathtubs.

Acrylic bathtubs do not stain from water and rust does not stick . The color scheme of acrylic bathtubs is initially set during manufacturing and does not fade or change over time.

Such a bathtub is easy to clean by simply rinsing with water, and if it is made of sanitary acrylic, it also has disinfecting qualities.

If a cast-iron bathtub contains three main design solutions - in the baroque style with legs stylized as lion paws, in the high-tech style with strict geometric shapes and the classic, familiar version of the bathtub - then the design of acrylic bathtubs is simply an explosion of solutions and imagination.

About steel baths

Despite the fact that cast iron is considered the traditional material for making bathtubs, metal and plastic products are quite common these days. And if in this case most buyers do not trust plastic, then people willingly purchase metal bathtubs.

After all, even over cast iron analogues they have several advantages, among which it should be noted:

- Low cost.

- Light weight.

- Durability and shock resistance.

- The metal heats up very quickly. It is enough to open hot water for a few seconds, and such a bath becomes warm.

Taking into account all the advantages, it can be noted that steel bathtubs are worthy competitors to traditional cast iron ones, but require minor modifications, namely insulation.

Preparing for insulation

How to insulate a bathtub and how to insulate a bathtub? These two questions concern many home craftsmen, and the answers to them are much simpler than they might seem at first glance.

For insulation, it is best to use polyurethane foam. This material is very easy to install, and you can carry out the thermal insulation process with your own hands without any difficulties or problems. Polyurethane foam is a universal insulating material that is used as insulation for windows and doors.

As the main or additional thermal insulation material, floors, roofing, it is also used to insulate loggias.

Most often, polyurethane foam is used to seal the joints and cracks between the main slabs. However, this heat insulator is often sprayed directly onto the insulated surface in a continuous layer.

To insulate the bathtub, you will need ordinary polyurethane foam, which is sold in cans and does not require the use of any special devices.

Advice! Insulation should be done before the initial installation of the bathtub, because dismantling an installed and tiled product is a rather difficult task.

Before work, you should make the necessary preparations:

- The product must be assembled and fully prepared for installation

. Install the drain siphon and secure the legs. - Clean the surface from dirt and dust

. - Before applying polyurethane foam, the surface should be well moistened

. We wet the cloth generously with water, washing away dust and dirt from the bathtub. - Next, you should prepare polyurethane foam for the insulation process

. To do this, shake the container thoroughly. If possible, you should warm it up further by placing it under running hot water. This will maximize the foam output from the can, saving you money and time.

Advice! If you subsequently plan to sew and cover with tiles, then you need to install a UD guide profile on the front side of the bathtub.

We insulate the bathtub

The instructions for thermal insulation involve several stages:

We should also talk about wall insulation. Here there may be slight difficulties with applying insulation. So, the foam can subside and flow down in large chunks. In principle, if you carry out the entire process carefully and slowly, without applying foam with a strong stream, then you will not have any problems.

But if you are not sure that you can handle this process, then it is better to wait a little until the foam applied to the bottom dries completely (this will take no more than half an hour).

After this, simply turn the bathtub on its side and continue working in the same way.

Metal bath foaming technology

And so, after we have figured out the goals, as well as the initial data that we have a metal bath, we will proceed directly to the process itself. First of all, we will need to purchase polyurethane foam. In order to foam a bathtub you need about two cylinders of high-quality foam. It’s best if you also have a specialized gun for polyurethane foam at your disposal, then you need to take the appropriate cylinders, but if not, then no. Next, you need to turn the bathtub over, place it so as not to spoil the enamel coating, and clean it of stickers and shipping packaging. Now comes the most crucial moment, namely, foaming the back surface of the metal bath. This will require some experience working with foam, since you cannot press too hard on the release valve, in which case too much foam will come out and uniformity will not be achieved. You can start foaming the bath from any place that is convenient for you. The main thing in all this is the uniformity of foaming and the maximum absence of non-foamed surfaces on the surface of the metal bath.

Which surface to foam, just the bottom...

or the whole reverse side….

It will also depend on your desire, of course, it is preferable to foam the entire back surface of the bathtub. During the foaming process, take into account the fact that the foam expands somewhat when it hardens, that is, between the rows of foam, when laying it, you can leave small gaps that close together. After foaming the bathtub, you must wait until the foam hardens, since if you install the bathtub right away, the uncured foam may peel off from the metal. An exception may be the case when the foam has nowhere to fall. For example, the distance between the metal surface of the bathtub and the wall is about 3-5 cm. It is also worth noting that the siphon on the bathtub should be installed before the process of foaming the bathtub. It is necessary to maintain a certain gap between the foam on the surface of the bath and the siphon. This must be done so that you do not have problems replacing it later.

Features of steel

Steel is a strong, durable and corrosion-resistant alloy that is actively used for the manufacture of plumbing equipment. Steel bathtubs belong to the lowest price category, are distinguished by a variety of models, colors and ease of installation, which is why they are deservedly popular among buyers. But during operation, you will notice that the water in products made from this material cools down faster, and when filled, it is noisier than cast iron bathtubs.

These features are associated with 2 characteristics of steel:

- High thermal conductivity. When hot water is drawn into a steel bath, the walls of the bowl quickly heat up, but also quickly remove the water, releasing heat to the environment. As a result, the water quickly cools down, which reduces the comfort of performing hygiene procedures. If you don't insulate your hot tub, you'll either have to get out of the bath or constantly add hot water, which causes your utility bills to skyrocket.

- High resonating ability. The walls of steel bathtubs are 2-3 times thinner than those of their cast iron counterparts, so drops of water falling on them from the height of the tap cause the metal to vibrate. This vibration intensifies the sound of the water, causing discomfort to household members.

Please note that the thinner the walls of the steel product, the stronger the vibration and noise when drawing water, the faster the water cools. Experienced craftsmen note that you need to choose bathtubs whose walls are at least 4 mm thick, then basic insulation done by yourself will help eliminate its shortcomings.

Improving the quality of steel models

The low price of steel bathtubs forces many buyers to purchase such models, but few know that you can get rid of their main disadvantages yourself, using affordable materials at hand. It is necessary to plan to insulate the outer surface of the bottom of the bowl before installation and connection to the sewer system, since after putting the bathtub into operation it is problematic to do this. To improve the quality of steel products, the following measures are taken:

Important! For both problems of steel bathtubs, there is a simple solution that comprehensively eliminates noise and reduces thermal conductivity. To improve the performance of inexpensive steel models, you need to insulate the bottom of the bowl with your own hands.

Materials for thermal insulation

An experienced craftsman has a wide selection of materials with which to insulate thin-walled steel bathtubs with his own hands. They differ in thermal conductivity coefficient, price and method of application. If the thermal insulation of the washing container is carried out before installation, you can use almost any material that suits you in terms of price and quality ratio. The most popular means of insulating steel products are:

Note! To properly insulate a container for washing on your own, using polyurethane foam sealant, you will need at least 3 full cylinders, the average price for each of which is at least 300 rubles. It is more economical to choose sheet polyurethane foam for thermal insulation, but this method is less effective.

Preparation

To properly insulate a steel washing container with your own hands, you need to carefully prepare the bathtub for use. If you apply polyurethane foam or glue thermal insulation material to an unprepared surface, you will not be able to achieve the optimal result. Before performing insulation, perform the following operations:

- You need to put cardboard, soft material or wooden blocks on the floor of the bathroom to place the washing container on them.

- Disconnect the font from the drainage system, disconnect the siphon and overflow.

- Turn the bowl upside down, and then lower it onto the prepared bars.

- Clean the outer surface of the bowl from dust or dirt.

- To degrease steel baths, use gasoline, alcohol or solvent.

Important! Before starting to treat the bathtub with polyurethane foam sealant, you need to thoroughly wet the surface to be treated with water to improve adhesion between the surfaces. If you are going to paste with sheet polyurethane foam, the walls and bottom of the font need to be dried, on the contrary.

Applying sealant

When studying how to seal the joint between a bathtub and tiles, you should consider in detail the procedure for applying sealant to work surfaces. They should be degreased and dried. To do this, you can use any solvent. To prevent the material from protruding far onto the bathtub or wall, masking tape is applied to them.

A can of sealant is inserted into the gun. After removing the protective cap, a small amount of substance is squeezed out from the tube. It is carried out along the entire joint. The sealant is an elastic substance. Therefore, it will close the cavity well. The required layer of sealant is applied in one pass.

The substance is first spread over the joint surface using a spatula. Next you will need a brush and soap solution. With the help of such means, the material that has not yet hardened is qualitatively leveled. Excess can be removed with a damp cloth.

Thermal insulation technology

When the preparatory work is completed, you can begin to insulate the steel bathtub. If you use polyurethane foam, you will need 2-3 cylinders. To cover the thermal insulation with sheet polyurethane foam you will need 2-2.5 square meters of material

. Insulation is performed according to the following algorithm:

Important! Thermal insulation of steel bathtubs immediately eliminates 3 problems of these models: rapid cooling, high noise and deformation of the walls, leading to chips on the enamel. Insulation can be done with your own hands without spending a lot of time, effort and money on this routine operation. This method of reducing the thermal conductivity of steel does not affect the appearance of the product.

Parquet and parquet boards

Floor coverings made of parquet and parquet boards are painted and varnished to protect against moisture and highlight the structure of the wood. Aggressive chemical components corrode the varnish if used on a parquet floor. To better remove stains, complete polymerization must be prevented. As soon as the polyurethane dries slightly and stops sticking to your hands, you need to carefully pull the edge of the foam mass and tear it away from the parquet. Traces can be removed with any cleaning agent.