An important stage of bathroom renovation is choosing and installing a door.

In a small-sized apartment, a classic swing block may be inappropriate, and then a sliding-type design will help get out of the situation.

What types of sliding doors to the bathroom are there and whether it is possible to make them yourself - we will discuss these questions now.

Pros and cons of sliding door construction

Sliding door design is widely used and installed in bathrooms. Significant popularity is due to the following advantages:

- The design features of the opening and closing mechanisms provide significant space savings. The door does not take up a single centimeter of extra space - there is simply no dead zone when opening them. It is this reason that explains such a great demand for sliding doors, since modern apartments are generally significantly limited in living space, which forces their owners to try to make the most efficient use of every living meter.

Saving space is perhaps the main reason for the popularity of sliding doors - Aesthetic appeal, harmonious compatibility with any apartment interior.

- Originality, effective execution, conciseness and stylish design.

- Manufacturers offer a huge selection of different models, made from the most modern and attractive materials, in various colors and decorative designs. Selecting a door that perfectly matches the surrounding environment is not difficult and depends entirely on the client’s taste. It is also possible to produce a custom design. When closed, the doors act as one of the interior elements.

- It is possible to easily install a mechanism for automatically opening and closing doors.

- Smooth and silent running.

- Long service life of compartment doors to the bathroom. The design is reliable and can last for several decades.

It should be noted here that, nevertheless, quite often there is a need to replace the rollers.

- Possibility of wide application for any, even not quite standard, openings. The design includes one or more doors, depending on the wishes of the owner and the size of the bathroom.

The original design of a folding door, which when closed looks like a regular swing door

Along with significant advantages, sliding doors used in the bathroom also have several disadvantages.

Disadvantages of using a sliding door design in the bathroom:

- The door does not fit tightly to the doorway and does not have sufficient tightness, so it is not recommended to use this type of door structure in combined bathrooms - unpleasant odors will penetrate through the cracks at the bottom or top of the door (depending on the type of suspension).

- For the same reason, sliding doors are not soundproofed, so you can sing in the bathroom only if you have a more or less acceptable voice and hearing, or if there are no potential listeners.

- Door rollers are subject to rapid wear and will need to be replaced if the door leaf is opened frequently.

- The lower guide rail needs to be constantly cleaned of accumulated dirt.

Installation

Installation of a sliding door is carried out as follows:

- Above the opening, a wooden beam is screwed to the wall with dowels, and the upper guide is screwed to it with self-tapping screws. It can be secured without timber - using brackets, but this option is less reliable.

- The extreme points of the upper guide are projected onto the floor using a plumb line and marked with a marker.

- At the marked points, the lower guide is screwed to the floor.

- Install the blade by inserting the rollers into the guides from the end side.

- They are screwed from the ends of the guides - stops that limit the movement of the rollers.

If it is necessary for the door to be locked, a vertical beam with a cut-out groove is screwed to the wall next to the opening. The width of the latter should be 5 mm greater than the thickness of the door. In this case, instead of a regular handle, a latch is screwed on, and its counterpart is attached to the beam.

A sliding door not only helps solve the problem of lack of space, but also transforms the interior, making it non-standard. Manufacturers offer a wide variety of products to suit every taste and budget. If you want to save money, it’s easy to make such a door yourself by purchasing rollers and guides at a furniture store.

What types of sliding doors to the bathroom are there?

When selecting sliding doors for a bathroom, you must be guided by the operational features of this room: the material of manufacture must be durable, wear-resistant, resistant to moisture and temperature changes. Sliding doors should be light in weight. If glass is used in production, it should be matte or completely opaque.

Bathroom doors must withstand high humidity, steam and elevated temperatures

Depending on the material, sliding doors are divided into two types:

- Solid or homogeneous.

- Paneled.

Solid doors are made from one material, which can be: glass, wood, plastic, linoleum, fibreboard, chipboard, metal, laminate.

Sliding door made of solid wood with finishing to match the bathroom flooring

Paneled ones are made by combining several materials; manufacturers offer very interesting combinations of two or more materials. More popular compared to solid ones.

Sliding doors on a wooden frame with clear glass inserts

Structure care

The main care for a sliding door for a bathroom and toilet consists of servicing the mechanism. The rollers, lock, and other moving elements are regularly lubricated. The supporting bottom rail is cleaned of dirt accumulation. Caring for the canvas usually involves washing. Simple stains are removed with clean water. If it is necessary to use detergents, take into account what material the sash is made of. To make wooden surfaces shine, rub them with furniture polish.

Door leaf materials: brief description, features

Bathroom doors must be made of materials that meet a number of criteria and requirements. Below we will look at the most popular of them for this correspondence.

Solid wood

Suitable for installation in a bathroom with significant restrictions, since wood is afraid of moisture and is susceptible to fungal diseases - as a result, it can become deformed and lose its performance qualities. Treating a wooden door leaf with special antibacterial compounds and waterproof emulsions can correct the situation to some extent and extend the service life of the product.

Solid sliding doors made of natural wood with a lacquered surface

Advantages: naturalness, beauty, stylishness.

Fibreboard, chipboard

Fiberboard – fibreboard (hardboard), obtained by pressing steamed sawdust. The thickness of the fiberboard is seven millimeters 7 mm. Chipboard doors are produced using the frame method. The advantage is the price. Disadvantages: short service life, significant susceptibility to mechanical damage, moisture and steam.

Such doors can be covered with decorative wood-like films or simply painted

Chipboard - chipboard (chipboard), is obtained by pressing dry sawdust and bonding them with formaldehyde resins. Advantages: ease of processing, resistance to water and steam, strength, low cost, wide range of colors.

Glass

Tempered glass is the most preferred material for the production of sliding bathroom doors.

Double-leaf frosted glass sliding door

Advantages:

- Absolute resistance to moisture and temperature changes.

- Not afraid of fungi and mold.

- Grace and aesthetic appeal.

- Strength, durability.

Despite the strength of tempered glass, this option is not suitable for rooms where small children live.

Flaws:

- Difficult to care for.

- Significant weight, creating a load on the door structure.

Metal

It is practically not used in the manufacture of solid doors; mainly, metal elements are used in paneled doors.

Sliding doors of original design on a metal frame with plywood inserts

Plastic

Single-leaf sliding door made of yellow plastic

Advantages:

- Durability.

- Impervious to rotting.

- Easy to care for.

- Cheapness.

- Moisture resistance.

- Lightness of designs.

Laminated materials

Laminated sliding systems can only be installed of good quality. In terms of its characteristics, the material is slightly inferior to plastic. The film used for lamination does not very reliably protect the product from moisture penetration.

Laminated single door compartment type

This option is perhaps the most budget-friendly. What exactly is lamination? This is covering the surface of the door with a special film, which can have a variety of patterns and imitate any material.

Combined options

The most popular combinations: glass-chipboard, glass-laminate, glass-PVC, solid wood - glass.

Combined door on a wooden frame with a mirror insert

Self-production

By making it yourself, you can save money and choose reliable options for materials and accessories on a small budget. When choosing a product, you need to consider the following parameters:

- opening width;

- size of the adjacent room;

- bathroom design;

- requirements for moisture resistance, strength and hygiene of the material.

The number of bathroom users also influences the choice of system. The more often the door opens, the fewer moving and unreliable elements must ensure its movement.

Material selection

Industrial structures are made from metal, glass, plastic, laminated MDF and wood treated with a moisture-resistant composition. At home, the canvas is made from wooden beams and moisture-resistant plywood.

Execution of work

To make a door you need:

- prepare a wooden beam with a cross-section twice as wide as the opening and bars with a cross-section of 5-7 cm;

- buy 2 guides, sheets of moisture-resistant plywood to fit the opening, galvanized or phosphated fasteners (nails, screws), a set of rollers;

- to improve the properties of the door, use thermal insulation and polyurethane foam;

- assemble the door frame from the bars, nail an additional bar in the area where the handle is attached (the length of the door should be 10-15 cm greater than the width of the opening);

- attach a massive wooden beam on top on which the guide will be placed;

- order 3 platbands and a false panel for the top rail;

- cover the door frame with a sheet of plywood, securing it with nails or self-tapping screws (for tightness, you can pre-coat the joint with PVA glue);

- Apply a layer of construction foam to the inside of the sheet and cover it with a layer of thermal insulation (for example, foamed polyethylene, mineral wool or polystyrene);

- fasten the second sheet of plywood by coating the joint around the perimeter with PVA and carefully cutting in the fasteners;

- attach external handles 15-17 cm from the edge (for internal handles you must first cut and trim holes of the required size);

- attach rollers to the upper and lower ends;

- if necessary, paint the plywood by adding pigment to the varnish for the wooden surface.

To work, you will need a hacksaw, tape measure, drill, wood glue or PVA, sandpaper and a jigsaw. If you have an electric jigsaw and a router, the grooves are more accurate. The canvas can be made not solid, but paneled.

Installation and operation

Installation is carried out in the following sequence:

- using anchors and a drill, secure a wide beam over the opening and attach the upper guide to it;

- project the extreme points of the upper element onto the floor with a plumb line, mark with a marker or construction tape, mount the lower guide;

- install platbands and false panels;

- install the manufactured canvas by inserting the rollers from the end of the guides;

- limit the movement of the rollers with stops, mounting them at the extreme points;

- to install a door lock, screw a vertical block with a drilled groove at the level of the handle (the width of the block should be 0.5 cm greater than the thickness of the leaf);

- mount the latch and attach the mating part to the block.

Before use, you need to check how freely the door moves and whether it rests securely on the rollers. If you have to make an effort to open, then the blade is installed unevenly or the guides are not parallel.

Selection of fittings and guides

The list of fittings for sliding doors includes: rails, rollers, special handles, latches. When selecting fittings, it is necessary to take into account the weight of the door, its structural features: dimensions, types of movement along the guides, types of fastenings.

It is best to purchase a sliding door fully equipped with all the necessary fittings

Main types of door designs

- Swing - traditional option. It is considered the most stable and reliable. Such doors close well, providing sound insulation. There are right- and left-handed ones. However, in tight spaces they may not be very convenient, as space is required to open the doors.

Swing doors - Sliding. To open, you need to push or roll back the door. For this purpose they are equipped with a special mechanism. They save space well, but don't close too tightly. This affects the quality of sound insulation.

Sliding doors - Folding - “accordion” or “book” doors. According to user reviews, the worst is provided by a. There are a lot of complaints about the strength of the structure. Some experts do not recommend such doors for the bathroom.

Folding doors

Door decor options

Glass doors provide the greatest scope for creativity. You can apply an ornament to this material, etch a beautiful pattern, or use sandblasting to paint a portrait or a whole picture.

A successful design solution - the corrugated surface of the glass inserts of the door leaf is in harmony with the mosaic of the bathroom flooring

Modern sliding doors have a very attractive design, they look stylish and original.

Materials

The choice of the method of opening sliding doors and the material of the door leaves depends on the imagination of the designer and the taste of the resident. Along with the technical conditions of use (frequent use, resistance to high room humidity, resistance to high temperatures, etc.), the model’s compliance with the style and nature of the room’s decoration and furniture is taken into account.

Glass

For wide, solid panels of overhead and hinged bathroom doors, frosted glass with various artistic design options is often used. Glass is not affected by moisture and temperature. Easily amenable to any cleaning. And thanks to the stylish combination of glass and metal supporting structures, the glass sliding door itself becomes an important element of room decor.

When using glass doors, you should remember their fragility and the noticeable weight of the solid glass sheet.

Wood and MDF

More versatile in application to various models of sliding doors are types of panels made of MDF and wood. To increase the durability of wood and MDF panels, special surface finishing is required. Impregnation with antiseptics against rot and mold, coating with polymer films and moisture-resistant varnishes help to significantly increase the service life of door panels. At the same time, modern materials for finishing wooden surfaces do not spoil the appearance at all, and often improve it.

The varnish of wooden bathroom door leaves must be renewed periodically. Without such measures, the slightest scratch on the surface threatens to cause warping.

Plastic

Plastic doors are distinguished from all others by their lightness and unpretentiousness. Plastic doesn’t care about temperature or humidity. It is easy to clean with any household detergent.

However, plastic also has its weak point. The soft surface of a plastic door leaf can easily be damaged by mechanical damage. When used carelessly, jams and scratches are noticeable and almost impossible to remove.

Advice! If you need bathroom renovation specialists, there is a very convenient service for selecting specialists from PROFI.RU. Just fill out the order details, the experts will respond and you can choose who to collaborate with. Each specialist in the system has a rating, reviews and examples of work, which will help with the choice. Looks like a mini tender. Placing an application is FREE and does not oblige you to anything. Works in almost all cities of Russia.

If you are a master, follow this link, register in the system and be able to accept orders.

Photo of sliding doors in the bathroom

Color selection

Many people are faced with the problem of choosing the color of their doors. It’s not clear what to focus on: the interior of the bathroom or the hall? Or maybe all the doors in the room should be the same?

If you follow all the recommendations, you can avoid annoying mistakes when buying a door:

- Doors located in the same hall should be combined in style and color.

- Try to match the door model to the bathroom interior.

- If you cannot find a door that suits the design of both rooms, it is possible to make a custom-made door with double finishing.

Whatever door you choose, it should be reliable, suitable for the interior and give you aesthetic pleasure.

Mounting a door on an open track

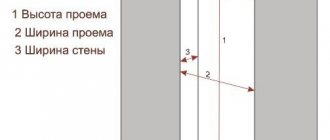

The first step in preparing to install such a door is to measure the doorway, which is not difficult to do using a regular tape measure.

These will be the dimensions of the canvas. A typical sliding door is usually 2 m in height, and the width can vary between 600-700-800 mm.

If you need to close an opening with larger or smaller dimensions, you should make a custom-made cloth, do it yourself, or remake an existing standard cloth.

You can even use an old or new leaf from a regular swing door.

The upper guide along which the door leaf moves is a metal rail. If the wall is not too smooth, the guide is fixed at a short distance from the wall

Making a sliding mechanism yourself is a complex, time-consuming, and sometimes simply impossible task.

It’s easier to purchase a ready-made set of rollers, guides and other system elements. The length of the sliding mechanism should be twice the width of the door leaf.

Experts recommend that novice craftsmen even take a guide with a small margin. Cutting off an unnecessary piece is not at all difficult, but if the bar turns out to be short, you will have to purchase a new one.

The figure clearly shows a diagram of the upper guide of the sliding door mechanism, the glass panel of which is held by the guide knife

You will also need fittings: handles and a door lock designed specifically for a sliding door. This element is not always necessary for an interior door, but in a bathroom it is quite relevant.

To install a mortise lock on a sliding door, you must first apply markings to the door, indicating the place where it will be located. Then a recess is made from the end of the door, the dimensions and configuration of which correspond to the parameters of the lock.

After this, another recess is made in the door frame beam (or in the second leaf, if a double door is installed) for the latch.

Both parts of the mechanism are inserted into the places prepared for them and secured with suitable fasteners.

When installing the lock and handles, you must ensure that these structures do not interfere with the free movement of the door leaf along the guides.

In addition, you should pay time and attention to finishing the doorway. To do this, you need a strip of width corresponding to the thickness of the doorway wall, as well as a special thrust strip for mounting the lock latch.

For the sake of the beauty of the interior, you need to take care of a beautiful platband. For a mechanism that is mounted on top of a wall, you should buy or make a decorative strip.

How to prepare the door leaf?

Most often, a wooden door is chosen for self-installation, since wood is accessible and easy to process.

In the process of preparing the canvas, several grooves are made in its ends. It is most convenient to perform them using a hand router. If this is not available, you can use other tools: drill, grinder, chisel and hammer.

In this case, the grooves are not always as neat as when working with a router. A three-millimeter groove is made in the center of the lower end for the lower guide.

This way the blade will acquire the stability necessary for precise movement. After this, the rollers and brackets from the sliding mechanism kit are connected to each other.

The rollers are inserted into the holes on the brackets and secured with nuts and washers, which are usually included in the kit. The assembled rollers must be installed on the upper end of the door leaf. To do this, grooves are made along the contour of the structure, the depth of which corresponds to the thickness of the mounting element.

It should be noted that such grooves, made with a chisel and hammer, do not look very neat. Perhaps the appearance of the canvas will suffer less if the rollers are simply screwed to the upper end without any grooves.

The installation technology makes it possible to do this.

Special locks are produced for sliding doors. Installing this type of mortise lock is not very difficult; you can do it yourself

After this, a lock and handles are installed. Due to the nature of the operation of such a door, the handles must also be recessed into the leaf so that they do not interfere with movement along the wall or in the frame.

To install door handles, make two symmetrical recesses on opposite sides of the door or one through hole. Such a hole is not difficult to make using a jigsaw and drill.

First you need to mark the outline of the hole, then drill the blade with a drill. After this, the cutting part of the jigsaw is inserted into the hole and a part of the blade is cut out along the contour.

After this, the door leaf can be considered ready for installation and installation of the sliding mechanism can begin.

For a sliding door, handles recessed into the thickness of the door leaf are usually chosen. Such handles do not interfere with the free movement of doors in different directions.

Installation procedure for the hanging system

To install a sliding door mechanism in a bathroom, you need to secure the appropriate guides above the doorway and on the floor.

If the walls and floor are level, installation will be easier. The main guide bar, which is usually located at the top, should protrude the width of the opening on one side and five centimeters on the other.

If you are installing a double-leaf door, the guide should protrude on both sides of the opening to the width of the leaf.

The installation height of the upper guide consists of the length of the door leaf, taking into account the size of the rollers, as well as a small gap at the bottom, which is usually 1-2 cm.

The top guide of a sliding door is usually hidden behind a decorative strip, which looks quite aesthetically pleasing and can decorate almost any interior.

You can attach the guide to a flat wall without any additional manipulations. If there is a slight curvature of the wall, the guides should be installed at a distance from the wall that will allow the canvas to move freely without touching the walls.

This distance is adjusted using a regular wooden strip, which is placed between the guide and the wall.

Completion of installation work

When the top guide is installed, the door leaf is hung on it. To do this, the rollers are simply placed on the side of the bar and moved in the desired direction.

After this, it is necessary to install a stop on the floor, for which a groove has already been cut at the lower end of the canvas. Perform this step as follows:

- The door leaf is moved to the maximum open position.

- The rubber stopper is secured to the top guide using a metal screw.

- Place the lower stop into the groove on the door leaf.

- Secure the stop to the floor with a dowel on the side in which the sash will move when opened.

- Move the canvas to the closed position.

- Install another rubber stop on the top guide.

- Secure the remaining end of the stop.

- Additionally, the position of the stop is secured with a couple more dowels.

After this, all that remains is to install a decorative strip that will hide the guide, and the work can be considered complete.

How to install a sliding door hidden behind a false wall is described in detail in the following video:

What is needed to create a design

Tools you will need to make the door:

- Measuring tape;

- Circular saw;

- Wood glue;

- Screwdriver and screws;

- Knife;

- Spray foam;

- Sandpaper or sanding block;

- Materials for primers, paints and varnishes;

- Drill.

Many sliding door designs can be made by hand

Materials:

- Wooden sheets, plywood sheets;

- Foam insulation;

- Door knob;

- Roller skates;

- Round brackets;

- Galvanized pipe;

- Round base plates.

The main factors of quality functioning

- Precise geometry of the entire structure, as well as individual parts of the sliding system.

- Strength and reliability of guides.

- The quality of the videos.

- Performance qualities of the materials used to make the doors.

Sliding doors to the bathroom and toilet cannot “break” completely at once. The most common breakdown is failure of the rollers. This element should never be underestimated, since a bad roller can lead to a chain reaction and failure of the most important parts of the sliding door system: the guide, the leaf. It is important to carefully and regularly maintain such structures.

1 of 3

Sliding doors, cassette systems and advantages

The main advantage of sliding cassette doors is that they do not take up even 1 cm of space. Such a door is mounted inside the wall and made at the factory in the form of a single block (cassette). The disadvantages of the design include the removal of part of the wall, which cannot always be done. For example, in houses with an old layout, the bathroom has a sloping shape, and installing a cassette door requires a complete redevelopment.

Installing a cassette door is done as follows:

- First, you should prepare an opening in the wall according to the size of the cassette - let it be a little larger so that nothing interferes with installation.

- You can install a cassette door into the finished opening. It is attached around the perimeter of the opening at the ends. Everything is clear here, and the only thing to consider is the installation level. Everything must be accurate, since even minimal distortions can shorten the service life several times.

- Next, we massage the hidden part in the form of an interior partition. Ideally, it should be covered with plasterboard, which can then be puttied and covered with tiles.

Door decoration is possible using platbands and slats. It's like a real arch, only not solid, but made of two parts, and a door moves between them.